Pure wood energy-saving lifting window

An energy-saving window and pure wood technology, applied in the direction of the wing frame, the arrangement of the wing leaves, the parallel glass structure, etc., can solve the problems of sliding window cleaning difficulties, reduced sealing performance, waste of manufacturing materials, etc., and achieve humanized use functions , excellent durability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

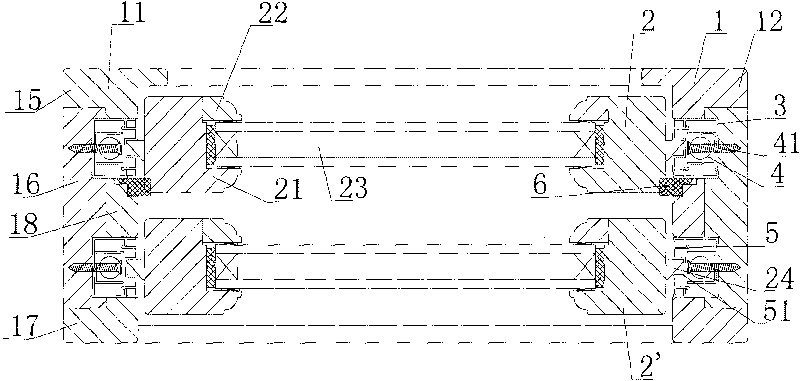

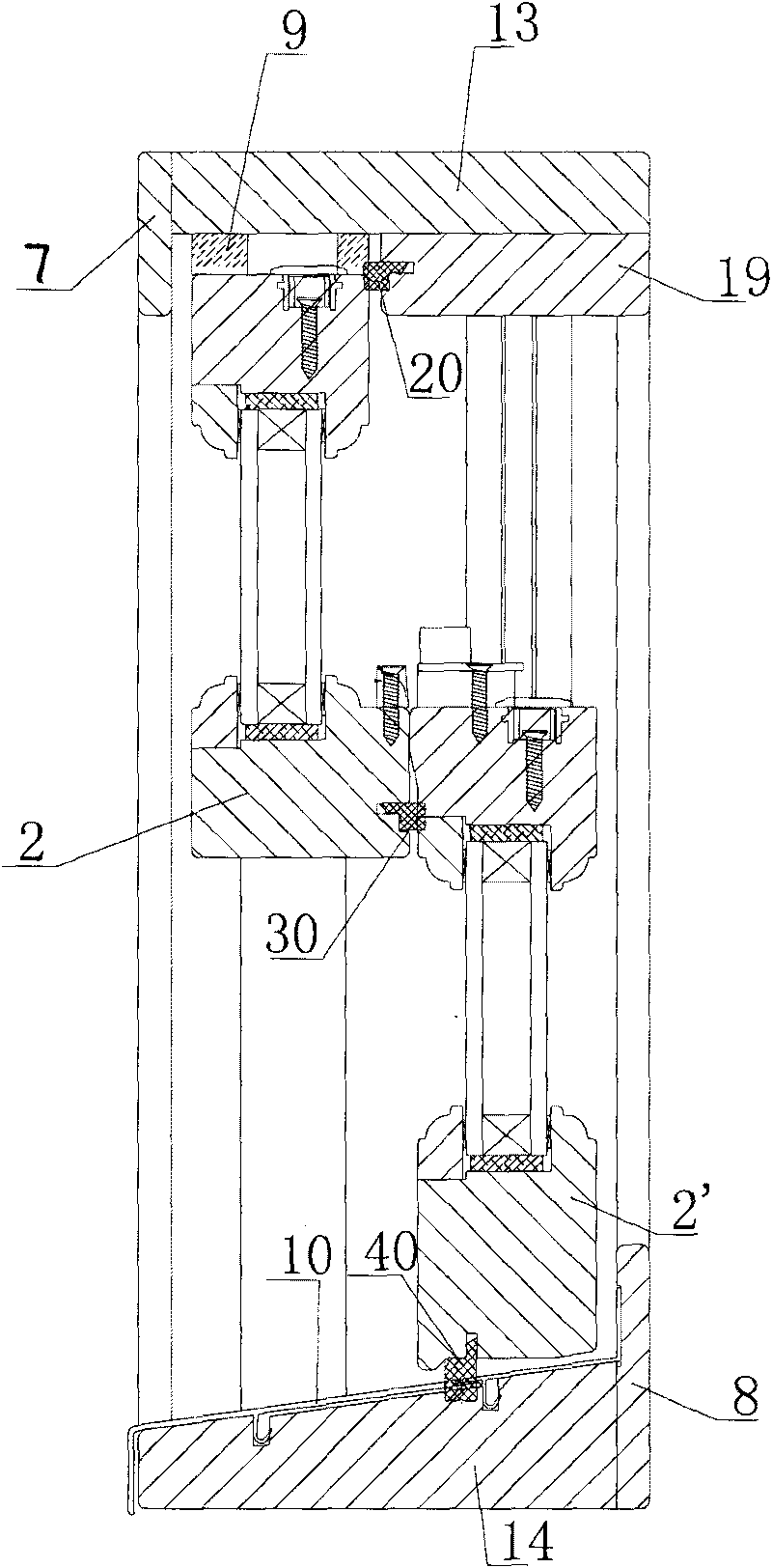

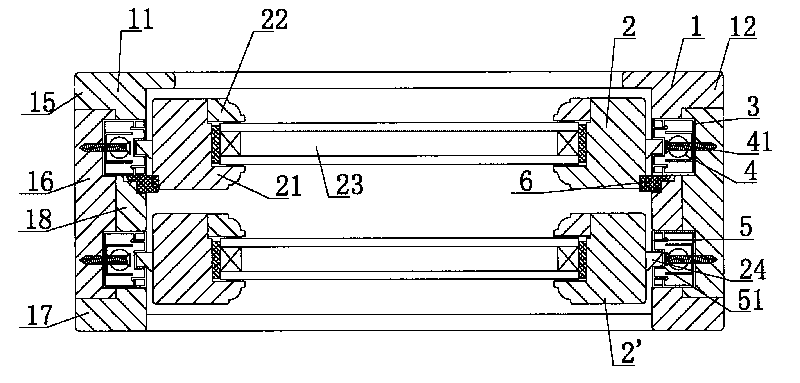

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 A pure wood lifting energy-saving window is shown. The lifting energy-saving window is composed of a window frame 1, an inner sash 2' and an outer sash 2. The inner and outer sides of the window frame 1 are respectively provided with sliding rails 3 in the vertical direction. The window sash 2' and the outer window sash 2 are composed of a wooden fan 21, a wooden pressing line 22 and a hollow glass 23 respectively. The inner sash 2' and the outer sash 2 are respectively arranged on the inner and outer slide rails 3 by a balanced puller 4. The balanced lifter 4 adopts a balanced lifter purchased from the market, and the balanced lifter 4 is fixed on the window frame 1 by screws 41 . Window frame 1 is made of wooden left mullion 11, right mullion 12, upper horizontal frame 13 and lower horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com