Method for detecting poor contact of battery voltage testing terminals

A technology for testing terminals and poor contact, applied in the direction of measuring current/voltage, measuring electricity, measuring electrical variables, etc., it can solve the problems of not being able to collect battery voltage signals, and the contact resistance between terminals and batteries is large, and achieves good test results. Short test time and easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

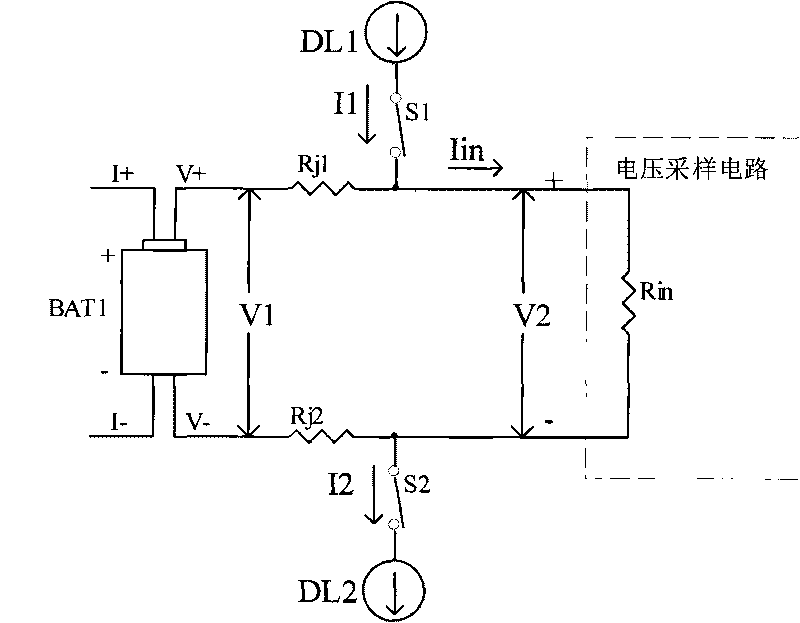

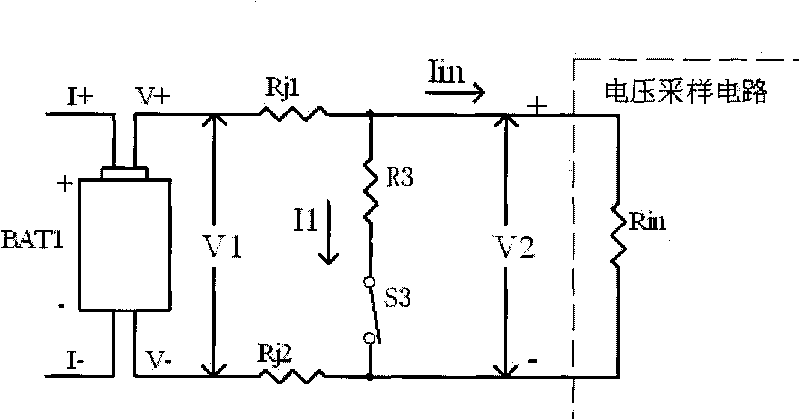

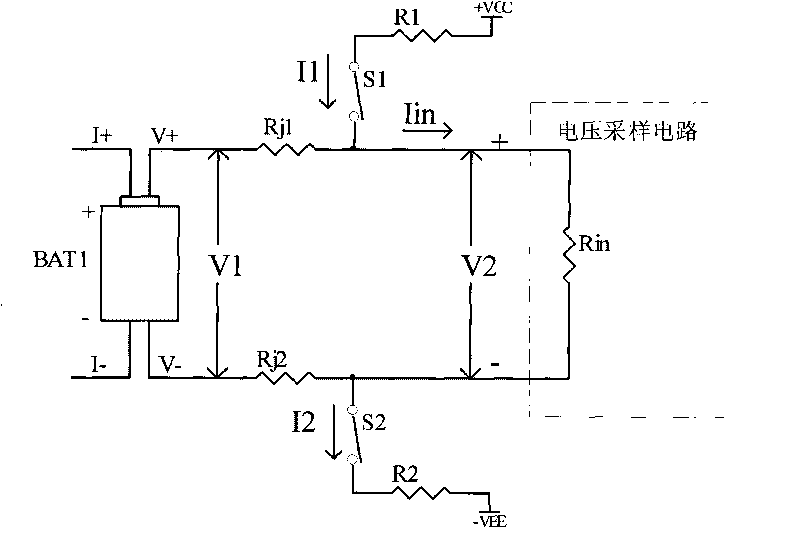

[0019] Such as figure 1 As shown, the principle of the method for detecting poor contact of battery voltage test terminals in the present invention is: since the battery is a voltage source with very small internal resistance, flowing a small current in a short time will not cause voltage fluctuations at both ends of the battery, so it can Add a test circuit that can control on-off, inject a small current into the battery through the battery voltage test line, and then measure and compare the voltage at both ends of the positive and negative voltage test lines before and after the current is on and off. If the voltage input value before and after the current on-off If there is no change, it indicates that the voltage terminal is in good contact. If the voltage changes significantly, it indicates that there is a large contact resistance between the voltage test termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com