Surface light source device and liquid crystal display device assembly

A technology for liquid crystal display devices and surface light sources, which is applied to the components of lighting devices, lighting devices, optics, etc., and can solve problems such as uneven color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

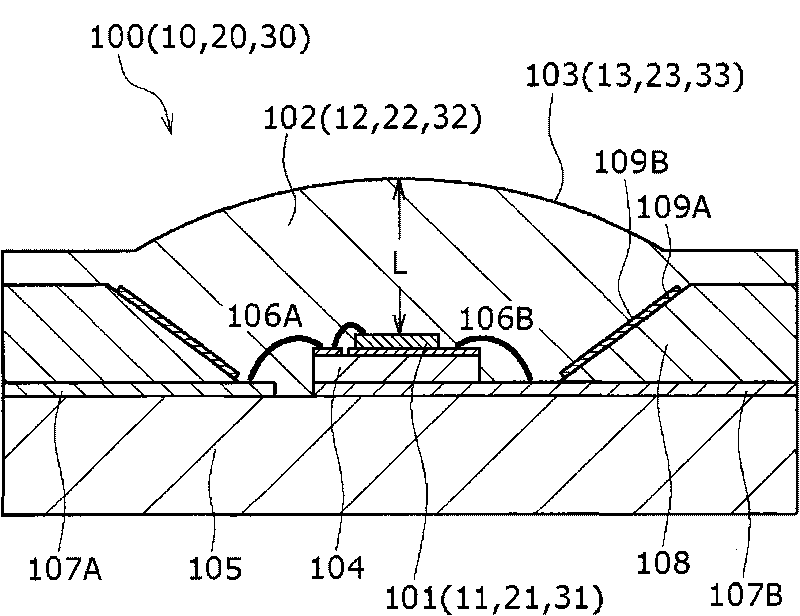

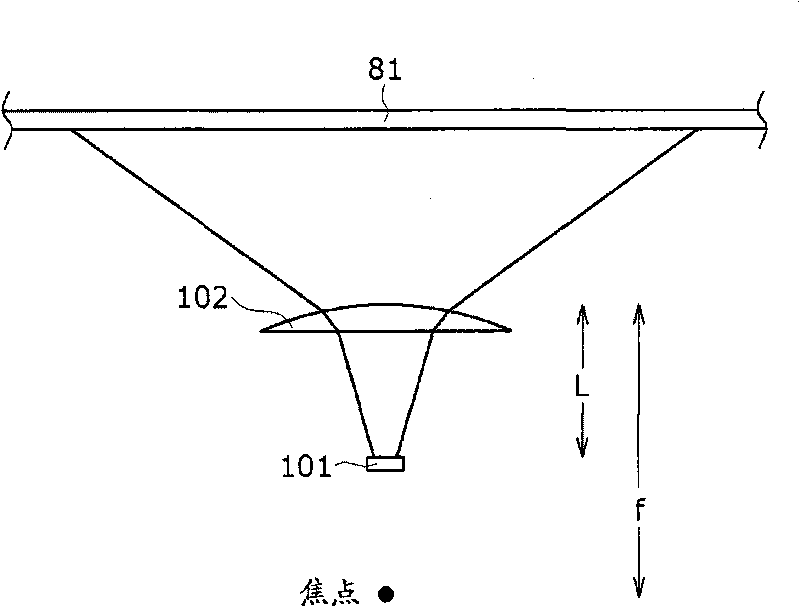

[0073] A first embodiment of the present invention relates to a surface light source device and a liquid crystal display device assembly according to the first and second embodiments of the present invention. The principle diagram of the liquid crystal display device assembly of the first embodiment is as follows figure 2 and image 3 shown. The schematic cross-sectional view of the light-emitting element assembly is shown in Figure 1A shown. A schematic partial end view of a liquid crystal display device assembly such as Figure 4 shown. A schematic partial end view of a liquid crystal display device such as Figure 5 shown.

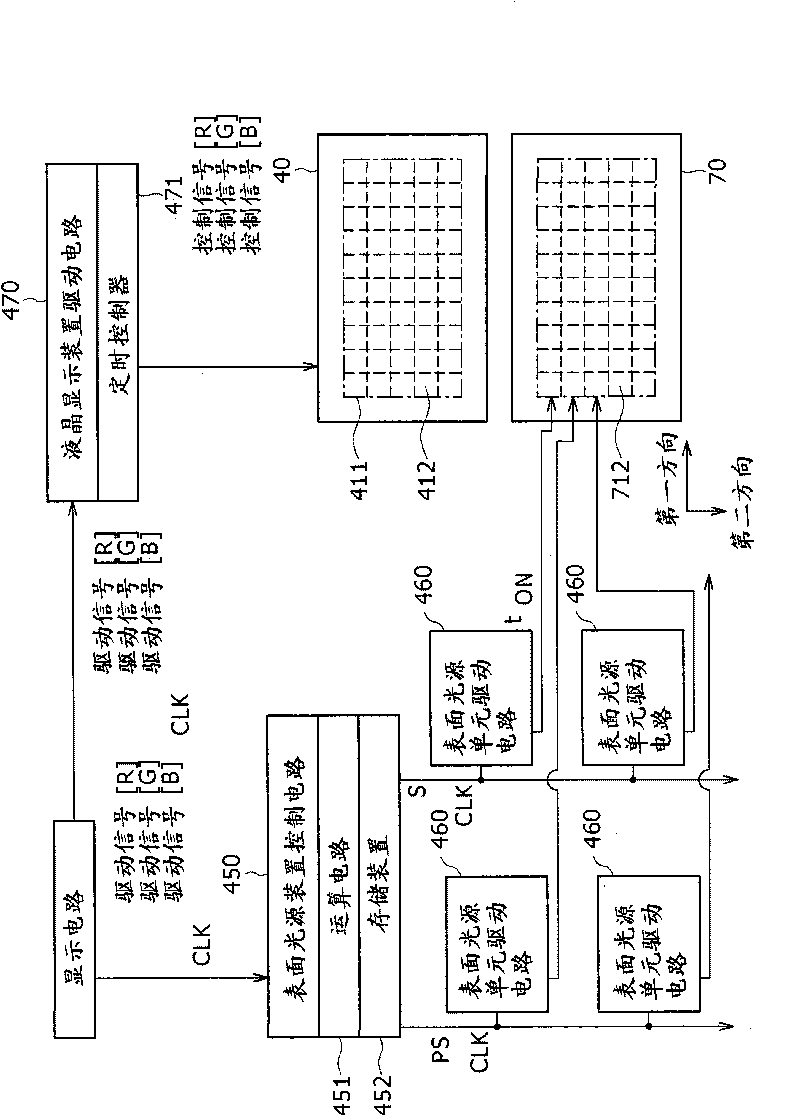

[0074] The surface light source device of the first embodiment illuminates a transmissive liquid crystal display device having a display area 411 formed of pixels arranged in a two-dimensional matrix from the backside thereof. further, such as figure 2 and image 3 As shown in the schematic diagram, the liquid crystal display device assembly ...

no. 2 example

[0159] The second embodiment of the present invention is a modification of the first embodiment. In the first embodiment, the light emitting element 101 is covered by the lens 102 without an intermediate gap therebetween. On the other hand, in the second embodiment, as Figure 11A As shown in the schematic cross-sectional view of , the light-emitting element 101 is opposite to the lens 102 with a light-transmitting medium layer 130 in between. Specifically, the recess 103A provided below the lower surface of the lens 102 is filled with the light-transmitting medium layer 130 . The light-transmitting medium layer 130 includes silicone gel resin (refractive index: 1.41), and the lens 102 includes polycarbonate resin with a refractive index of 1.59. Except for the above features, the same configuration and structure as the lens 102 and light emitting element assembly 100 in the first embodiment can be adopted as the configuration and structure of the lens 102 and light emitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com