Directional current based shutting method of high-speed switching device of industrial enterprise power supply,

A fast switching and current technology, applied in circuit devices, emergency power supply arrangements, electrical components, etc., can solve problems such as interference in industrial enterprises, inability to lead out protection action contacts, and no protection, and achieve the effect of avoiding the expansion of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

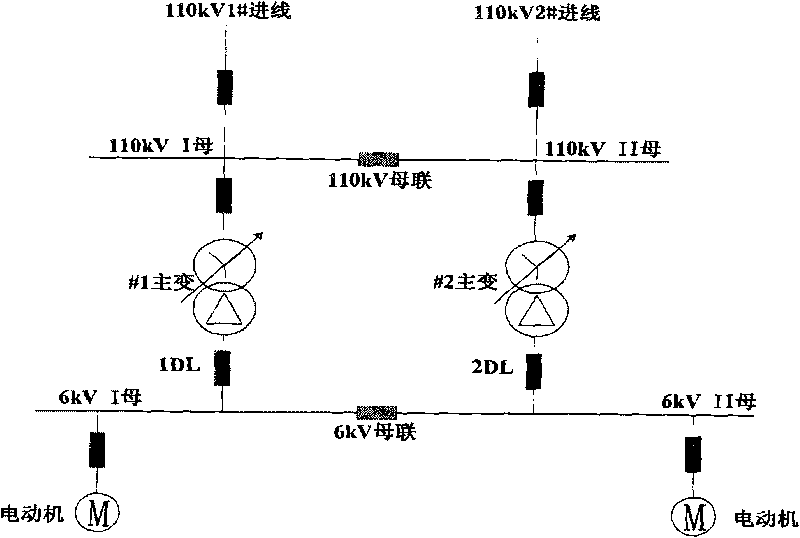

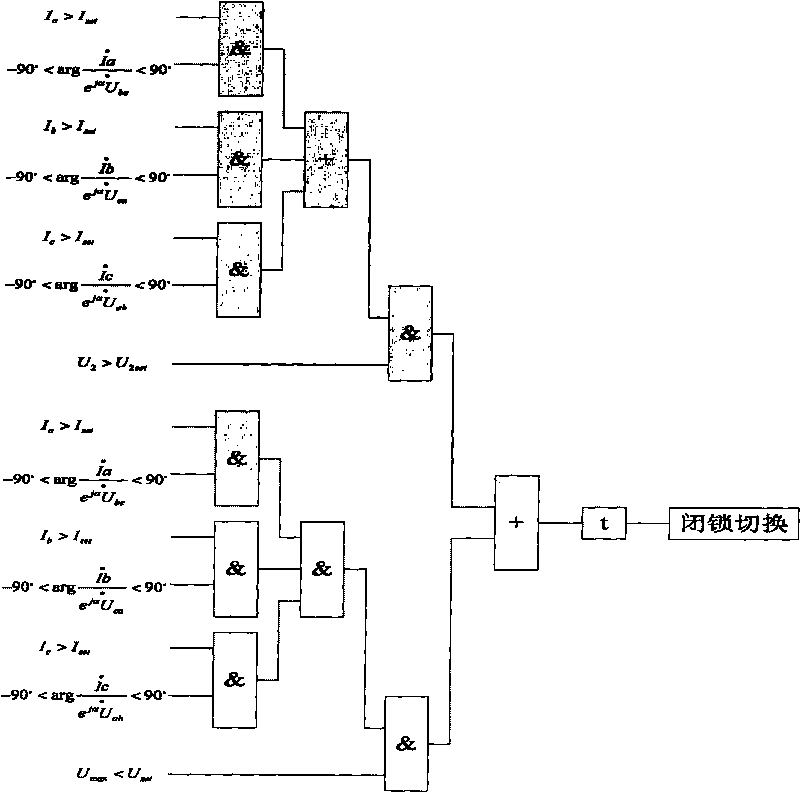

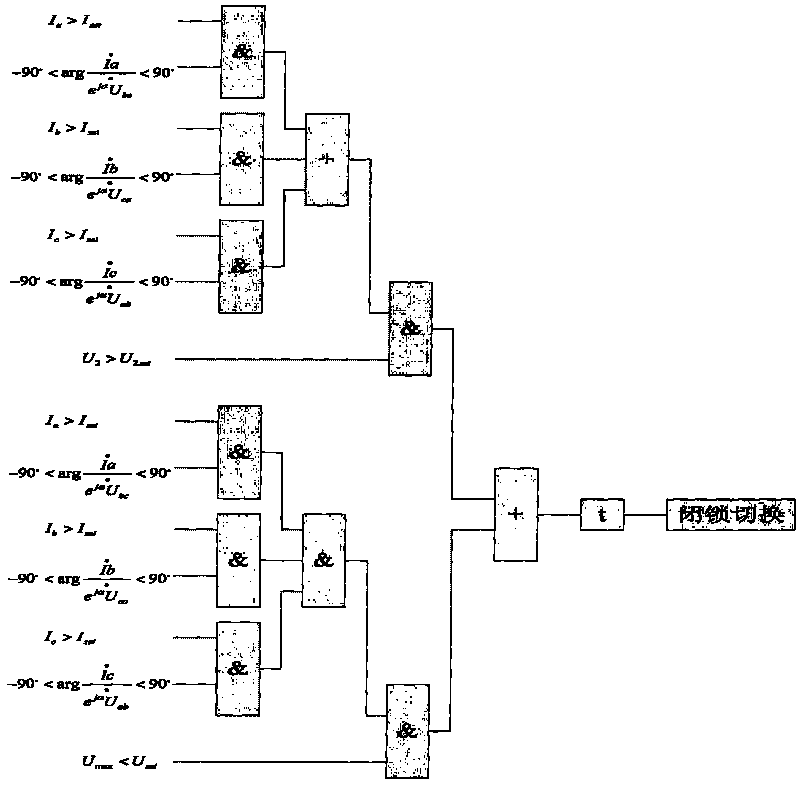

[0020] The invention integrates the directional current criterion, the negative sequence voltage criterion and the low voltage criterion into the fast switching device of the power supply to form a locking logic; during normal operation, the current amplitude at the incoming line switch is less than the rated value, and the direction flows to the working bus, and the working The busbar voltage amplitude is between 95% and 105%, and the phase sequence is positive sequence. When an asymmetric fault or a symmetrical fault occurs on the working bus and its equipment, the current amplitude increases, and the direction flows to the working bus, and a large negative sequence voltage or low voltage appears on the bus.

[0021] The current amplitude increase and direction flow to the working bus are taken as the main criterion for external power failure detection.

[0022] The bus negative sequence voltage and low voltage criteria are used as the means to prevent misjudgment.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com