Auto trimming oscillator

A technology of oscillator and oscillator frequency, which is applied in the automatic control of power, electrical components, etc., can solve problems such as difficult to find solutions, and achieve the effect of low-cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

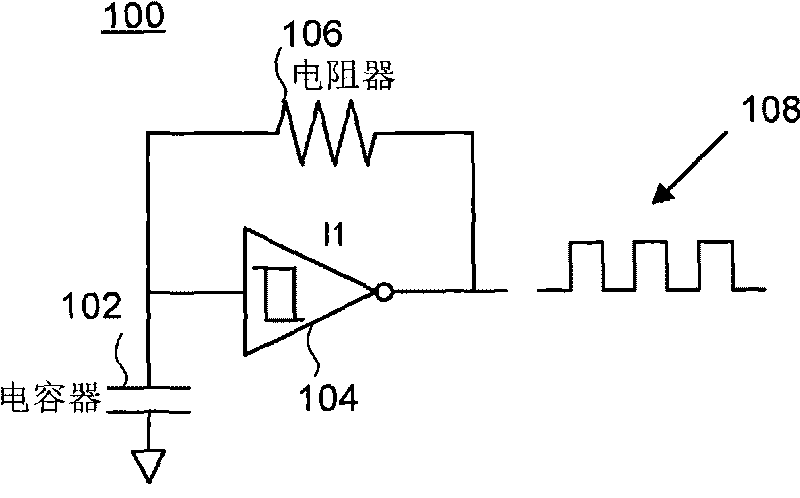

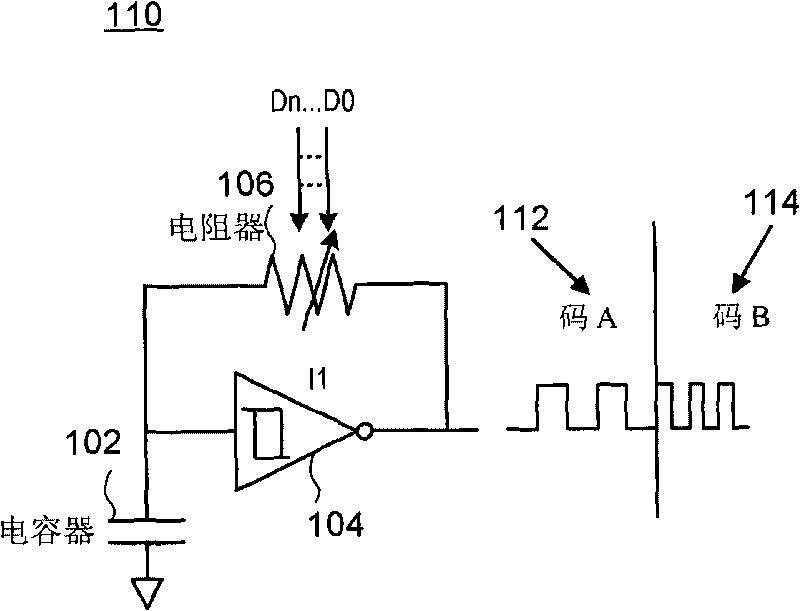

[0013] Example automatic fine tuning oscillator

[0014] image 3 It is a block diagram of an exemplary automatic fine-tuning oscillator using SAR. In some implementations, the automatic fine-tuning oscillator 300 may include an oscillator 302, a frequency detector 304, a comparator 306, and a SAR 308. In the exemplary configuration shown, the SAR 308 outputs a digital code that can be used to iteratively fine-tune the oscillator 302 based on the difference between the oscillator 302 frequency (Fosc) and the reference clock frequency (Fref). In some implementations, the oscillator 302 may be a conventional RC oscillator, such as the RC oscillator 110 shown in FIG. 1B. Other types of oscillators (for example, Wien Bridge oscillator, Twin-T oscillator, phase shift oscillator) can also be used.

[0015] In some embodiments, the frequency detector 304 is figure 2 The number of edges of both the oscillator 302 clock and the reference clock are counted in the time period T defined by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com