In-line planting device of transplanter

A planting device and in-line technology, which is applied in the field of in-line planting devices of transplanters, can solve the problems of complex control mechanism, leakage of seedlings, and difficulty in meeting the needs of large-area dense transplanting and planting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

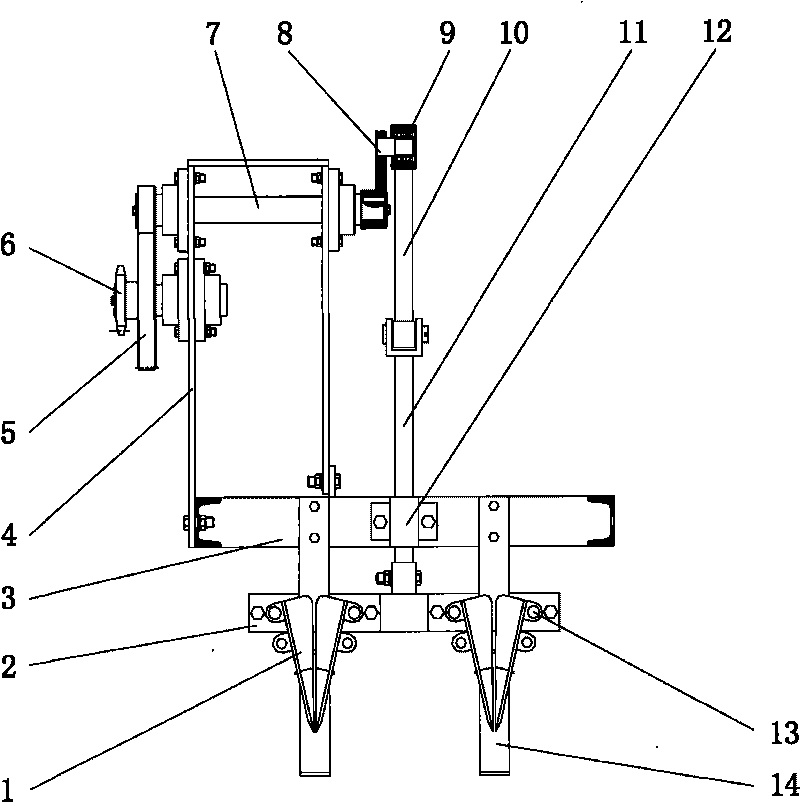

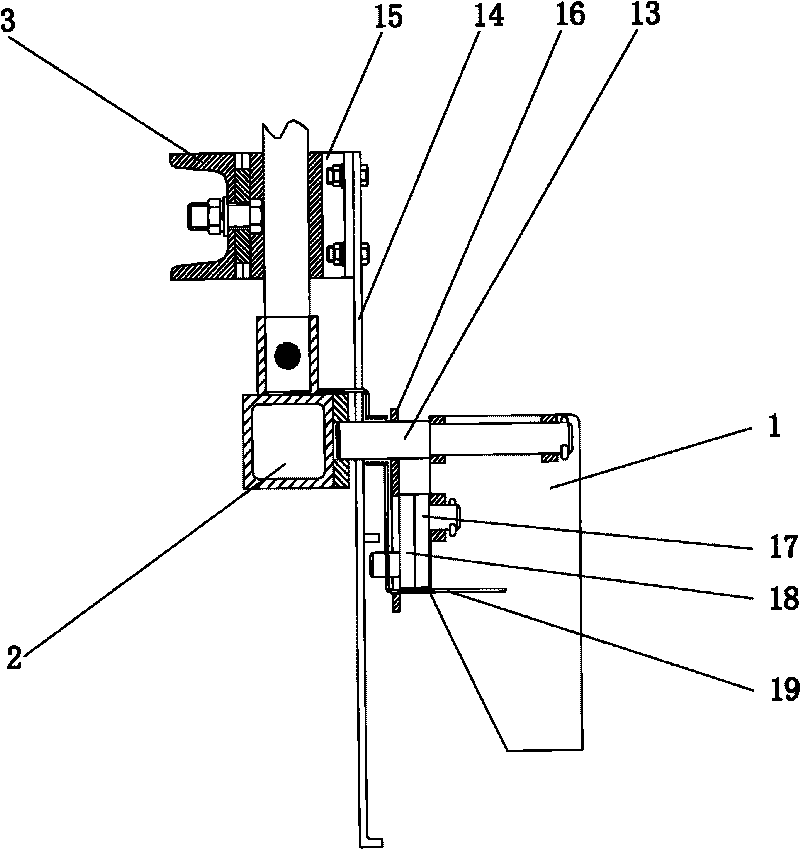

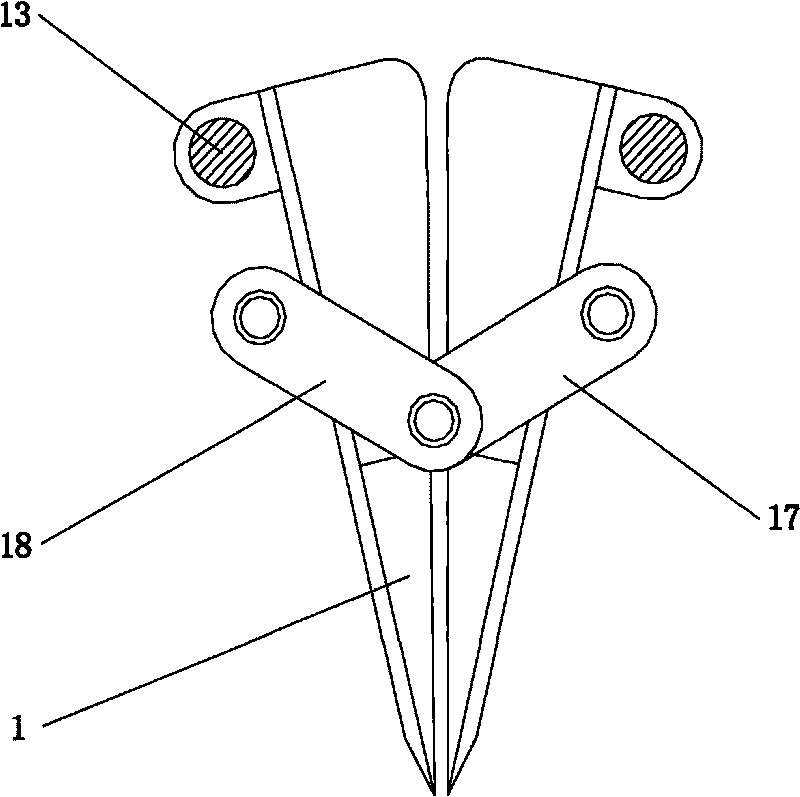

[0017] Attached figure 1 It is an embodiment of the present invention. The in-line planting device of the transplanting machine of the present invention is driven by the sprocket 6, the gear 5, and the shaft 7 to drive the crank connecting rod mechanism to move. The rotating crank 8 drives the push rod 11 through the connecting rod 10 to make a reciprocating linear movement, thereby realizing the reciprocating linear movement of the planting device. The planter 1, the limiting plate 16, and the spring 19 are all installed on the planter support 13 and are fixedly connected with the push rod 11 through the cross beam 2 to form an integrated planting device, and the entire reciprocating movement follows the push rod 11. The positioning rod 14 is fixed on the frame 3 and is located between the limit plate 16 and the fixed plate of the planter support 13. In order to avoid collision or friction during the movement, there is sufficient clearance between them. When the planter 1 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com