Method for producing liquid milk product containing grains

A technology for dairy products and granules, which is applied in the field of producing liquid milk products containing granules, can solve problems such as waste and unqualified fruit content in products, and achieve the effects of reducing waste, having multiple product forms and having good taste.

Inactive Publication Date: 2010-06-02

INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, if the workers make mistakes or the machine fails, such as the wrong configuration of the concentration of the granular material, the online mixing ratio is not carried out according to the preset setting, and the sterilizer has problems after the online mixing, etc., it will directly cause the fruit content of the produced products to be unqualified. , will cause unavoidable waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

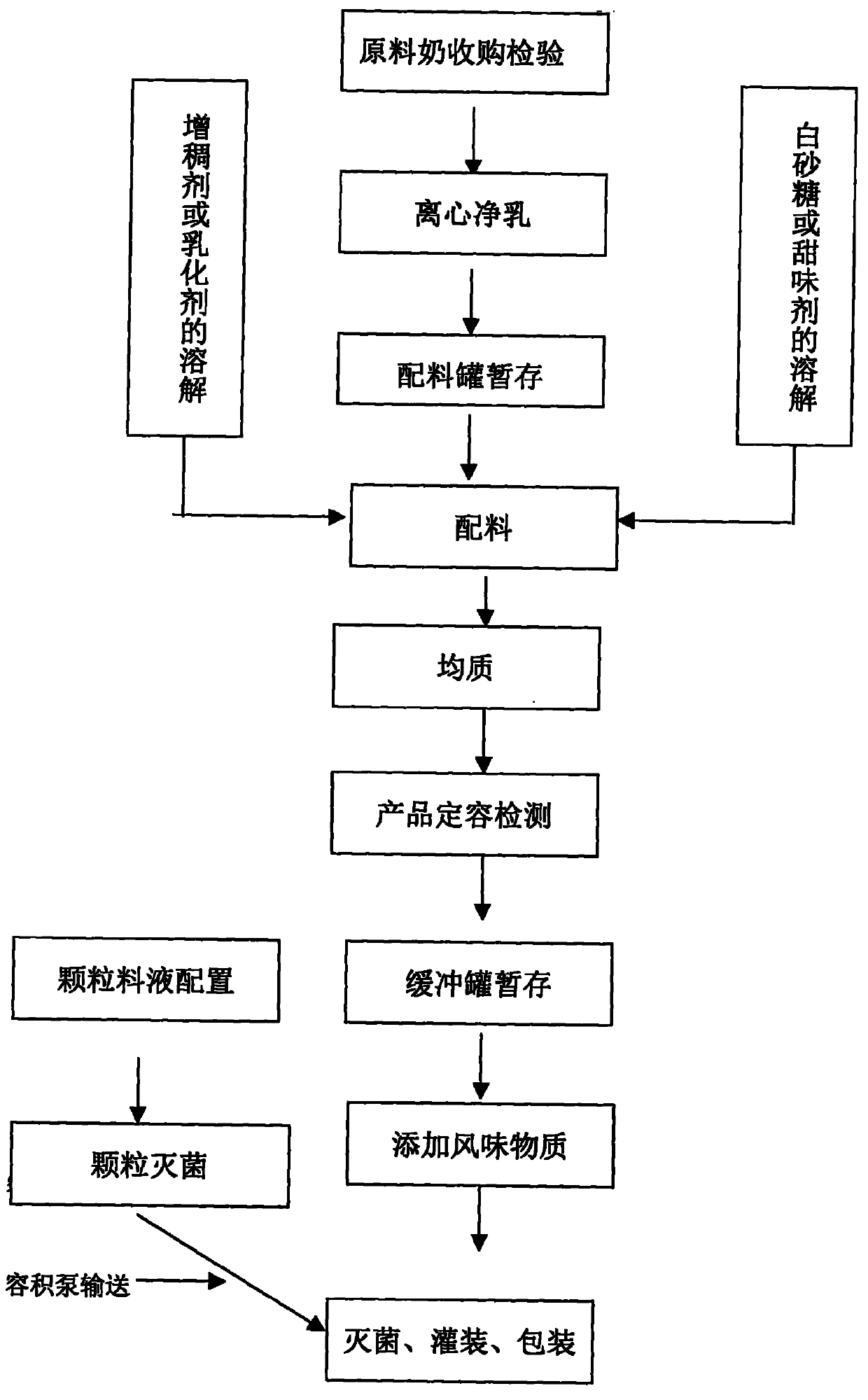

The invention relates to the field of production methods of liquid milk, in particular to a method for producing liquid milk product containing grains, comprising the following steps of: (1) preparing grain solution, adding grains into a grain dosing tank, adding water, preparing the required concentration and then slowly stirring to evenly distributing the grains in the solution; (2) preparing a base material: mixing a stabilizing agent and / or an acidity regulating agent with milk, evenly stirring and homogenizing; (3) sterilizing grain liquid and the prepared grain liquid by using a tubular sterilizing machine; (4) filling: filling the sterilized grain liquid to a packaging unit and then filling the sterilized base material; and (5) overturning the packaging unit to evenly mixing the grains and the base material. By the method, dependent preparation, dependent sterilization and dependent filling of the base material and the grain liquid can be realized and the addition of the grains can be better controlled in the production process, thereby reducing the inevitable waste caused by errors in the production process.

Description

technical field The invention relates to the field of liquid milk production methods, in particular, the invention relates to a method for producing liquid milk products containing particles. Background technique At present, there are many liquid milk products with added particles on the market, but the production process of the products is basically the same, mainly including the following steps: raw milk inspection, ingredients, constant volume, temporary storage or adding flavor substances, sterilization, filling, among which, generally Add particles before constant volume, and the sterilization equipment adopts casing type sterilization, which will cause the amount of particles in each position in the batching tank to be basically the same even under the condition of agitation and rotation in the batching tank, and finally in the batching tank. Each packaging unit in the finished product cannot guarantee that the content of the particles is basically the same, and the st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23C9/152

Inventor 巴根纳赵六永刘华孙远征马国文

Owner INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com