External bottle brushing machine

An external bottle brushing machine and bottle brushing machine technology are applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems that the bottles cannot be completely cleaned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

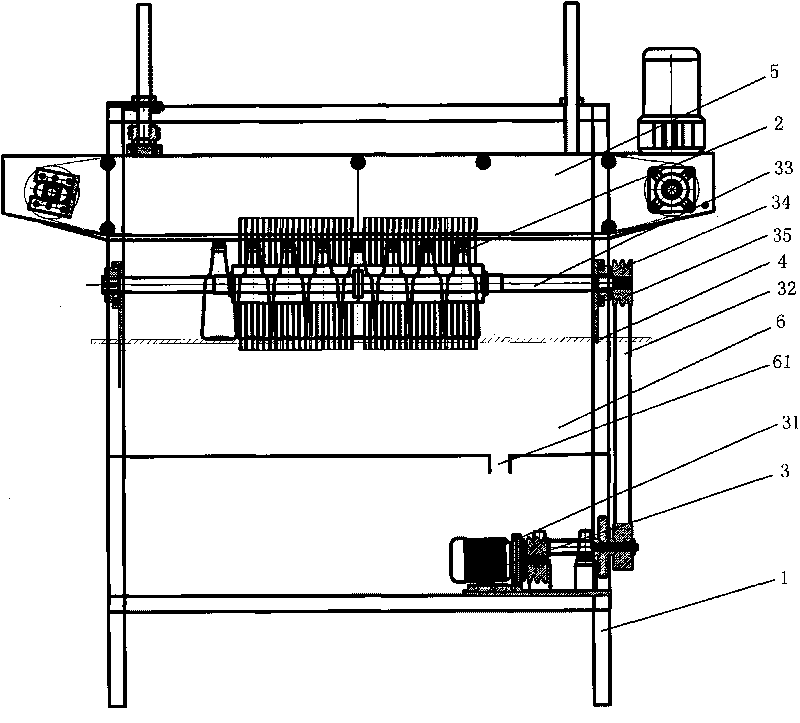

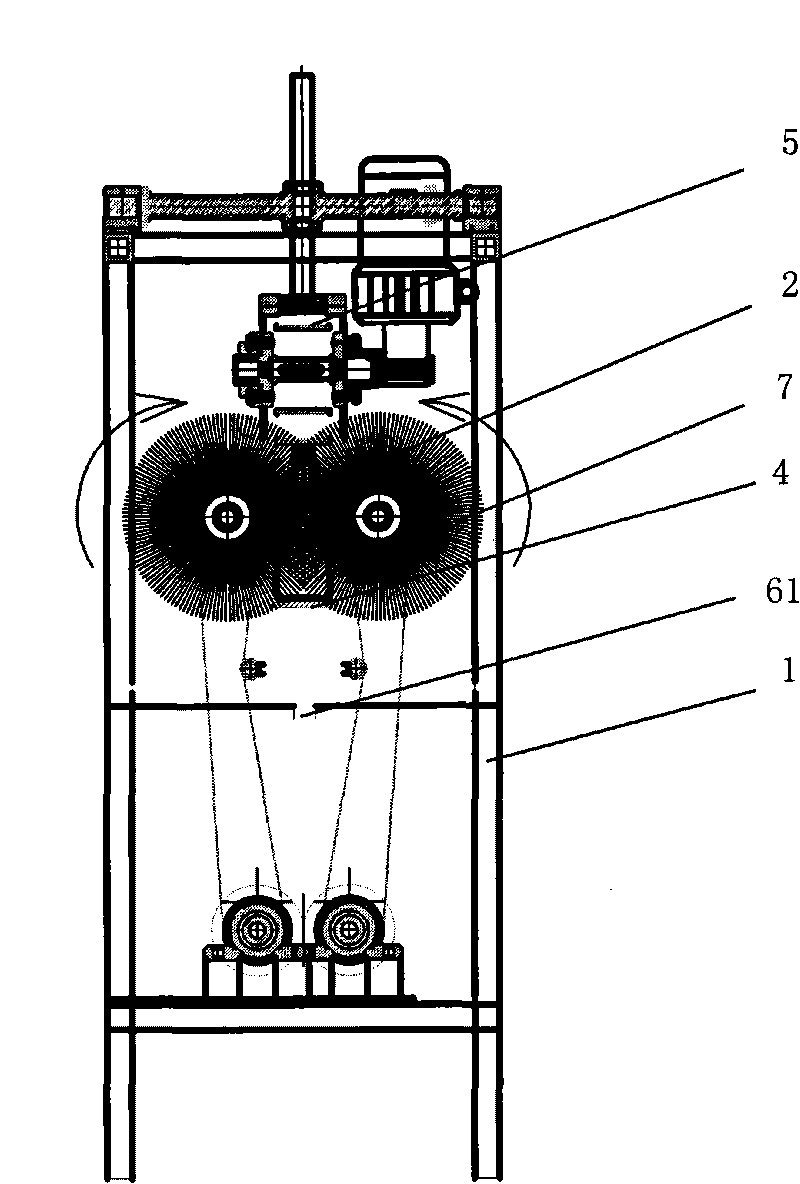

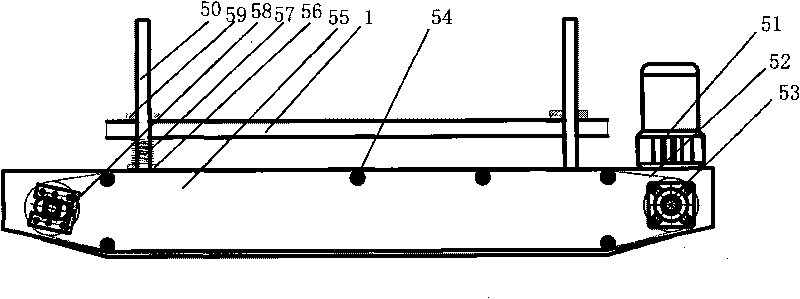

[0018] Below in conjunction with accompanying drawing, the present invention is further elaborated, with figure 1 is the standard, and the front is towards the viewer.

[0019] like figure 1 and figure 2 As shown, the outer bottle brushing machine of the present invention includes a frame 1, the left and right directions of the middle position of the frame 1 run through a conveyor belt 4 that is driven to the right by an external drive, and two side-by-side brushes 2 are respectively arranged on the top of the conveyor belt. The brush 2 can contact the outside of the bottle placed on the conveyor belt. The brush 2 is driven by the transmission mechanism 3 and rotates inward with the conveyor belt 4 as the center. The purpose of cleaning is achieved by rubbing the outside of the bottle 7. Of course, if this part is hairy The longer the length of the brush 2, the longer the cleaning time and the better the cleaning effect. In addition, a water receiving pool 6 is provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com