Method of forming car steering knuckle forging die cavity

A forming method and steering knuckle technology, which are used in forging/pressing/hammer devices, forging/pressing/hammering machines, manufacturing tools, etc., can solve the problems of high scrapping ratio, large displacement force, and difficulty of forgings. Achieve the effect of improving the life of the die, balancing the dislocation force, and reducing the failure rate of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

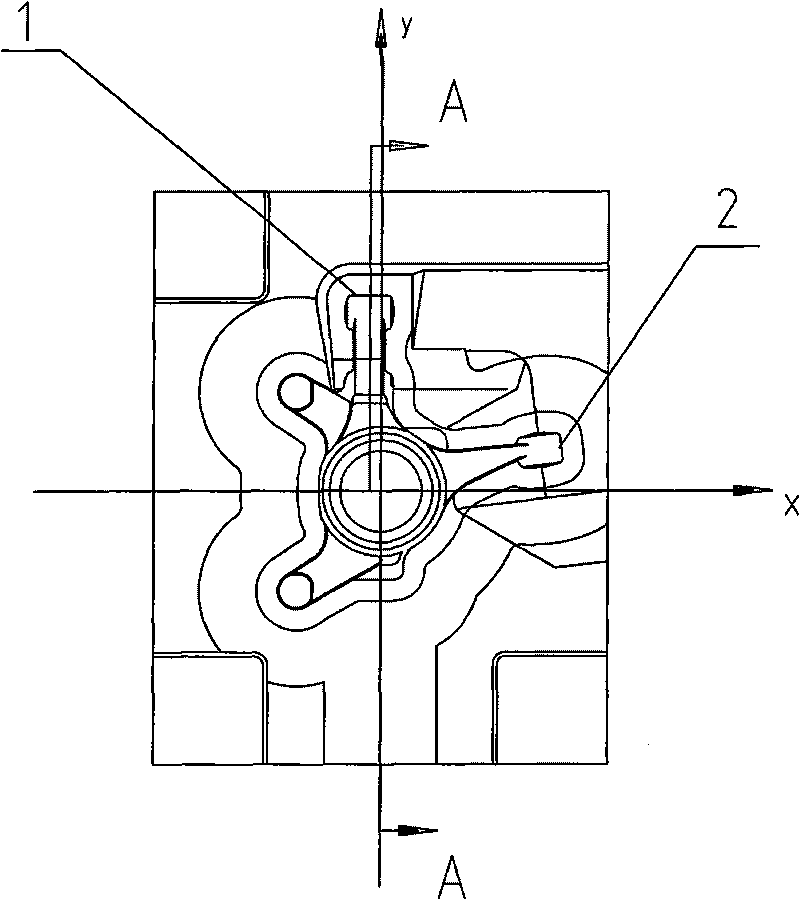

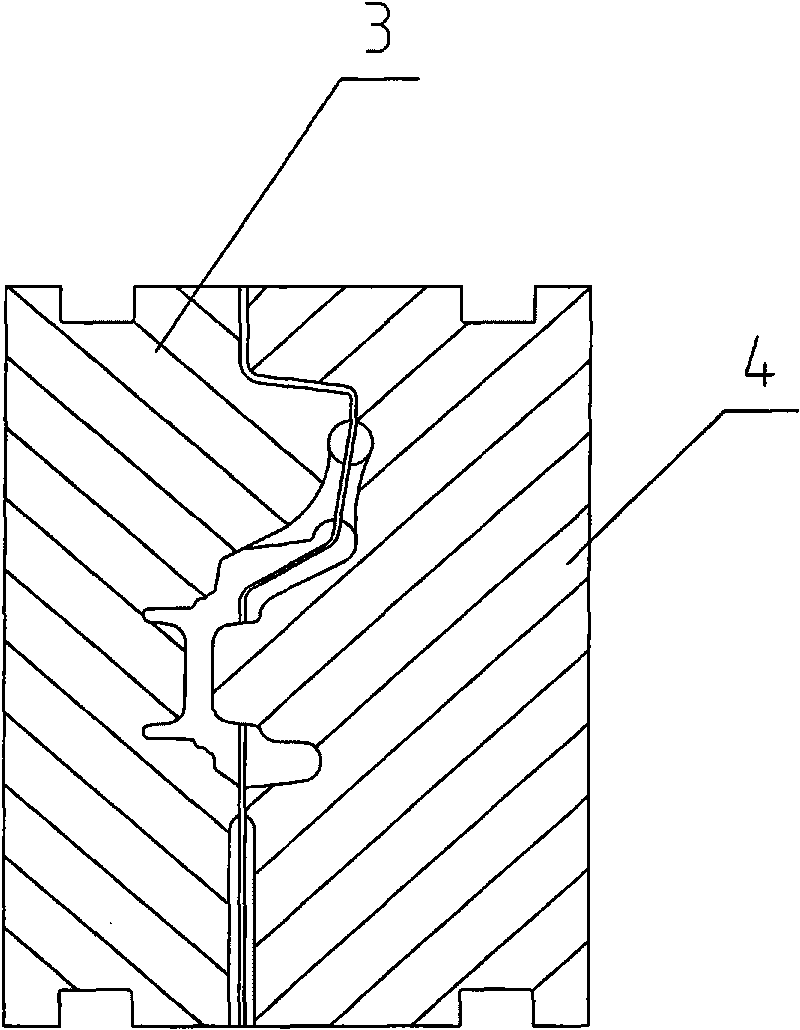

[0027] The car steering knuckle forging model cavity forming method of the present invention combines Figure 3 to Figure 10 The specific description is as follows: the method changes the step of blank extrusion molding into the step of metal direct filling, and changes the arrangement direction of the pre-forging and final forging mold cavities, so as to reduce the difficulty of forming and reduce the misalignment force.

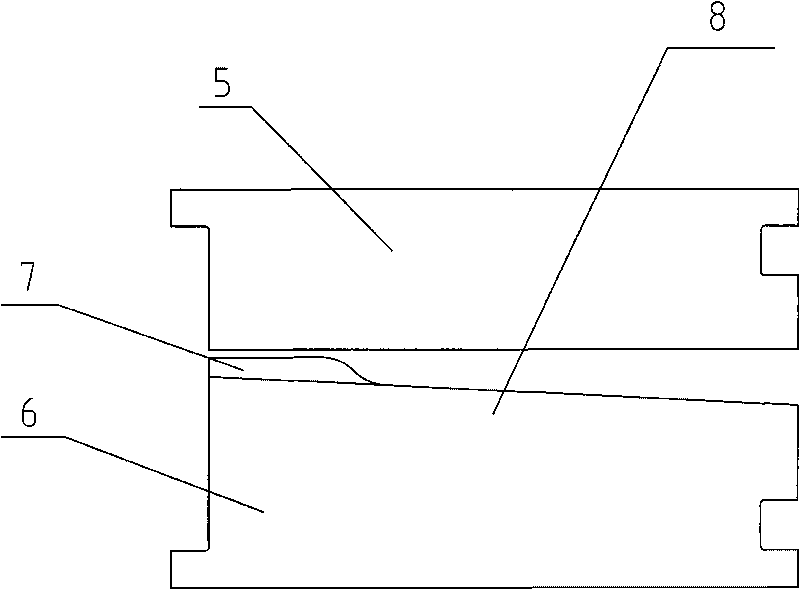

[0028] When implementing the present invention, the material is cut first, then the blank is heated to a high temperature of 1180-1250° C., and then placed on the splitting table 8 to press out the preliminary formed shoots. The splitting table 8 consists of an upper mold 5 and a lower mold. Die 6 is formed, and described lower die 6 is a working surface that is obliquely downward, and there is a small boss 7 at the end of this working surface that is obliquely upward. The shape and size of the splitting table are determined according to the projection of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com