Method for treating catalytic ozone oxidation water

A technology for oxidizing water and ozone, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of activated sludge poisoning, affecting the mineralization degree of water body, and cannot be treated. Achieve the effect of high ozone utilization rate, solve the inhibition effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

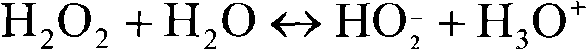

Problems solved by technology

Method used

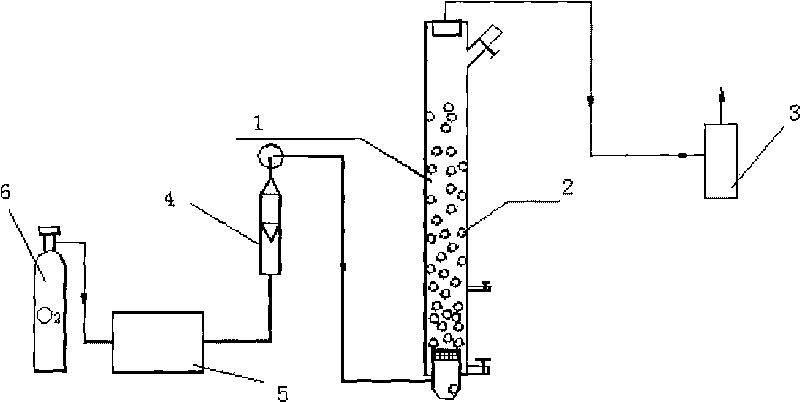

Image

Examples

Embodiment 1

[0029] Prepare 500mL of acetic acid solution containing 50mg / L, add acid solution to adjust the pH to 0.5, then add it to the ozone reactor, add 2.5mg of hydrogen peroxide and 0.25mg of Ti 4+ The titanyl sulfate is stirred until the titanyl sulfate is completely dissolved, and ozone is introduced.

[0030]The dosage of ozone is 25mg / min. At the beginning of the experiment, samples were taken for detection after 30 minutes of reaction.

[0031] As a comparison effect, under the same experimental conditions, the experiments of hydrogen peroxide catalyzed ozonation and titanium ion catalyzed ozonation to remove the same concentration of acetic acid were compared.

[0032] Detection method: acetic acid adopts ICS1500 ion chromatography.

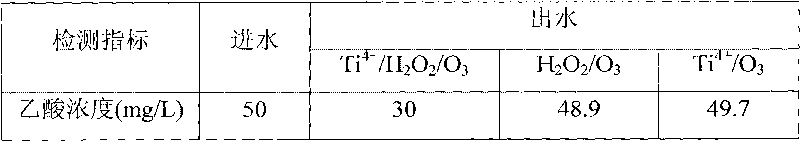

[0033] The effect after water sample treatment for 30 minutes is shown in Table 1:

[0034] Table 1

[0035]

Embodiment 2

[0037] Prepare 500mL of acetic acid solution containing 200mg / L, add acid solution to adjust the pH to 2.5, then add it to the ozone reactor, add 200mg of hydrogen peroxide and 50mg of Ti 4+ The titanyl sulfate is stirred until the titanyl sulfate is completely dissolved, and ozone is introduced.

[0038] The dosage of ozone is 100mg / min. At the beginning of the experiment, samples were taken for detection after 30 minutes of reaction.

[0039] As a comparison effect, under the same experimental conditions, the experiments of hydrogen peroxide catalyzed ozonation and titanium ion catalyzed ozonation to remove the same concentration of acetic acid were compared.

[0040] Detection method: acetic acid adopts ICS1500 ion chromatography.

[0041] The effect after water sample treatment for 30 minutes is shown in Table 2:

[0042] Table 2

[0043]

Embodiment 3

[0045] Prepare 500mL of acetic acid solution containing 400mg / L, add acid solution to adjust the pH to 3.5, then add it to the ozone reactor, add 100mg of hydrogen peroxide and 40mg of Ti 4+ The titanyl sulfate is stirred until the titanyl sulfate is completely dissolved, and ozone is introduced.

[0046] The dosage of ozone is 95mg / min. At the beginning of the experiment, samples were taken for detection after 30 minutes of reaction.

[0047] As a comparison effect, under the same experimental conditions, the experiments of hydrogen peroxide catalyzed ozonation and titanium ion catalyzed ozonation to remove the same concentration of acetic acid were compared.

[0048] Detection method: acetic acid adopts ICS1500 ion chromatography.

[0049] The effect after water sample treatment for 10 minutes is shown in Table 3:

[0050] table 3

[0051]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap