Aluminate long afterglow luminescent material and preparing method thereof

A long afterglow luminescence, aluminate technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

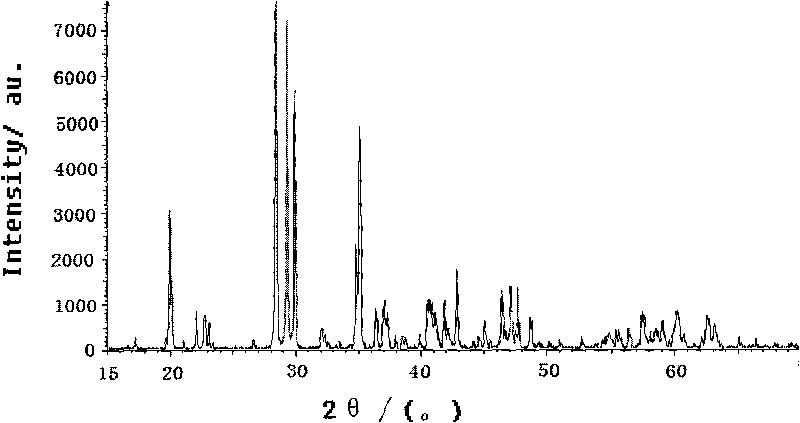

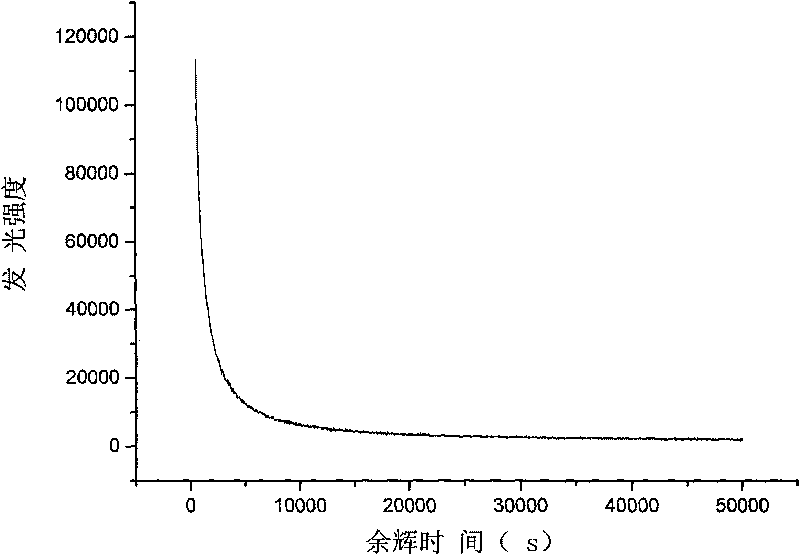

Embodiment 1

[0026] According to the general formula M (1-x-y) al 2 o 4 :Eu x , Dy y First weigh ①Sr(NO 3 ) 2 20.845g, ②Al(NO 3 ) 3 9H 2 O 75.022g, ③Eu(NO 3 ) 3 ·6H 2 O 0.139g ④Dy(NO 3 ) 3 ·6H 2 O0.273g, dissolve respectively with deionized water; Wherein the solid-liquid ratio is 1: 1~2; After mixing each solution again, add to 600ml (NH 2 ) 2 CO solution, the (NH 2 ) 2 The concentration of the CO solution is 0.4mol / L, the molar ratio of the added amount of the urea solution to the soluble material is 5-8:1, then heated to 96°C and stirred to form a precipitate, and the precipitate is separated from the liquid; Wash 1-2 times with deionized water, and then dry the washed product in a vacuum drying oven at a drying temperature of 90°C to obtain composite precursor fractions with fine and uniform particle sizes. Then at 90% N 2 ~10%H 2 Under a mixed atmosphere, keep it in a sintering furnace at 1300°C for 4 hours to obtain SrAl 2 o 4 :Eu 2+ , Dy 3+ The long-lasting l...

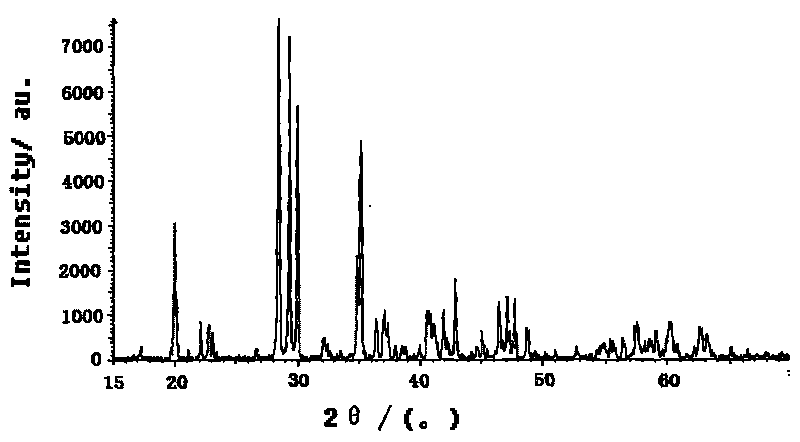

Embodiment 2

[0028] According to the general formula M (1-x-y) al 2 o 4 :Eu x , Dy y First weigh ①Ca(NO 3 ) 2 23.260g, ②Al(NO 3 ) 3 9H 2 O 75.022g, ③Eu(NO 3 ) 3 ·6H 2 O 0.139g ④Dy(NO 3 ) 3 ·6H 2 O0.273g was dissolved in deionized water respectively, wherein the solid-to-liquid ratio was 1:1-2; after the solutions were mixed, they were added to 800ml (NH 2 ) 2 CO solution, the (NH 2 ) 2 The concentration of the CO solution is 0.6mol / L, the molar ratio of the added amount of the urea solution to the soluble material is 5-8:1, then heated to 99°C and stirred to form a precipitate, and the precipitate is separated from the liquid; Wash with deionized water for 1-3 times, and then dry the washed product in a vacuum drying oven at a drying temperature of 120° C. to obtain a precursor powder. Then at 90% N 2 -10%H 2 Under a mixed atmosphere, keep it in a sintering furnace at 1400°C for 3 hours to obtain CaAl 2 o 4 :Eu 2+ , Dy 3+ The long-lasting luminescent material is gro...

Embodiment 3

[0030] According to the general formula M (1-x-y) al 2 o 4 :Eu x , Dy y First weigh ①Ba(NO 3 ) 2 25.741g, ②Al(NO 3 ) 3 9H 2 O 75.022g, ③Eu(NO 3 ) 3 ·6H 2 O 0.139g ④Dy(NO 3 ) 3 ·6H 2O0.273g was dissolved in deionized water respectively, wherein the solid-to-liquid ratio was 1:1-2; after the solutions were mixed, they were added to 800ml (NH 2 ) 2 CO solution, the (NH 2 ) 2 The concentration of the CO solution is 1mol / L, the molar ratio of the amount of the urea solution added to the soluble material is 5-8:1, then heated to 80°C and stirred to form a precipitate, and the precipitate is separated from the liquid; Washing with deionized water for 1-3 times, and then drying the washed product in a vacuum drying oven to obtain the precursor powder. Then at 90% N 2 -10%H 2 Under a mixed atmosphere, keep it in a sintering furnace at 1600°C for 5 hours to obtain CaAl 2 o 4 :Eu 2+ , Dy 3+ The long-lasting luminescent material is ground and sieved to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com