Processing system for changing chrome tanning wastewater into resource and processing technique thereof

A treatment system and treatment process technology, applied in the field of chrome tanning wastewater treatment, can solve the problems of large amount of CaO sludge, increased treatment costs, poor settling properties, etc., and achieve the effects of fast settling speed, reduced treatment cost, and dense settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

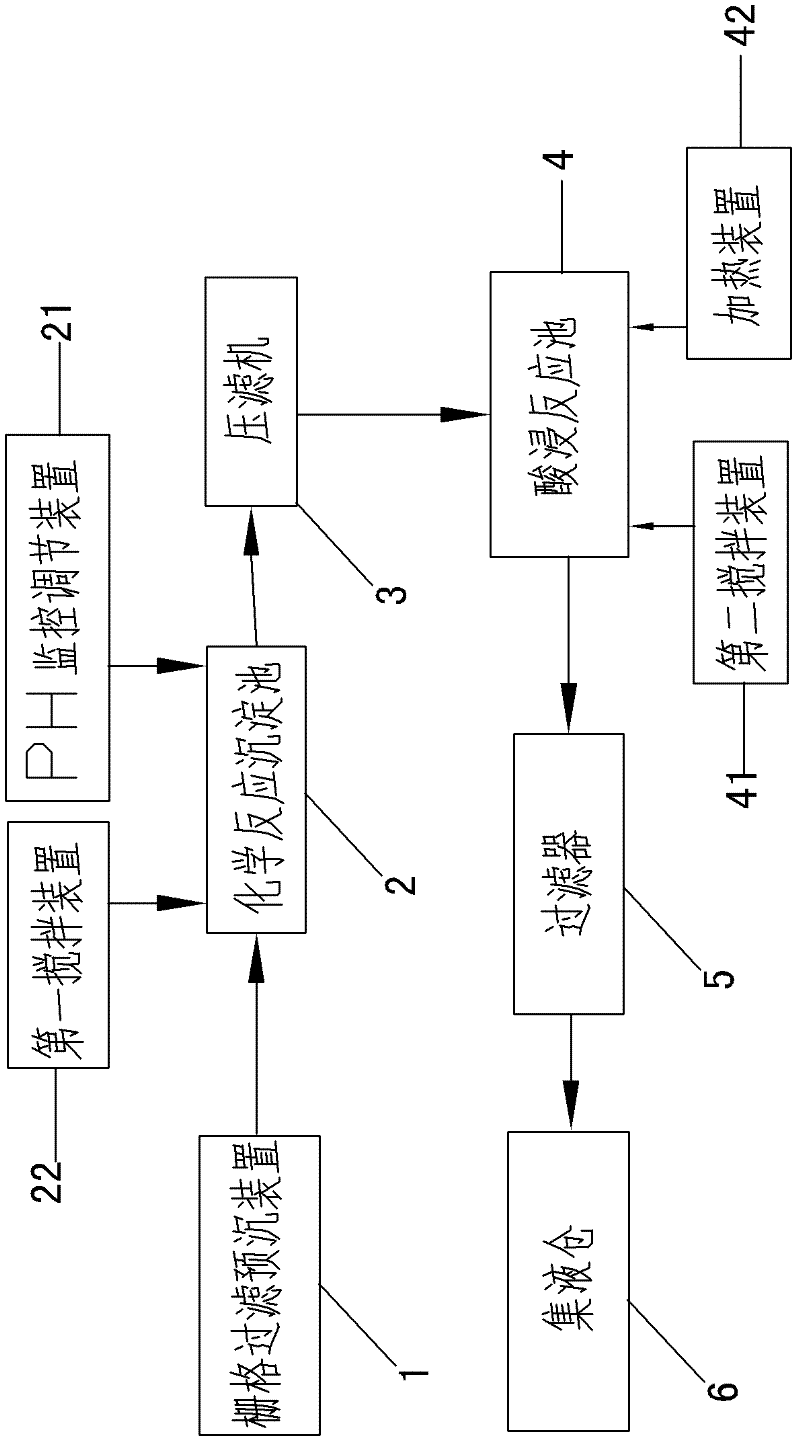

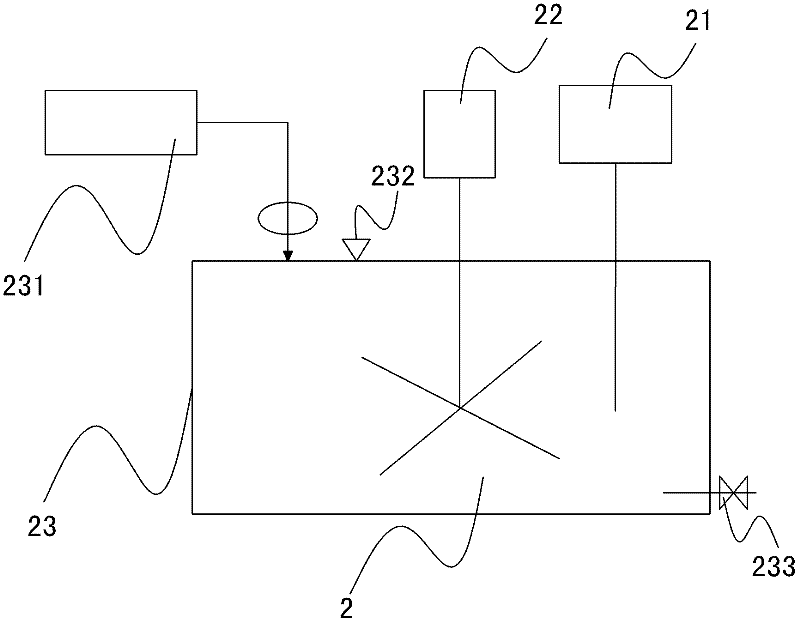

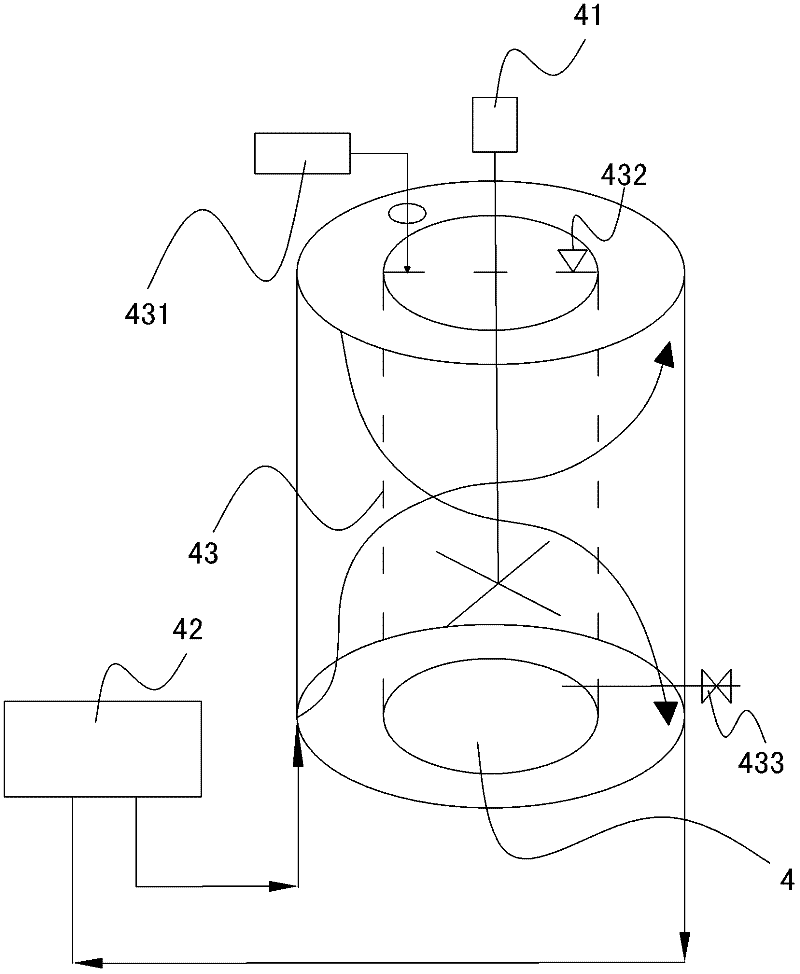

[0025] refer to figure 1 , figure 2 and image 3 , a resource treatment system for chrome tanning wastewater of the present invention, comprising a grid filter pre-sedimentation device 1, a chemical reaction sedimentation tank 2, a filter press 3, an acid leaching reaction tank 4, a filter 5 and a liquid collection bin 6, The output port of the grid filtration pre-sedimentation device 1 is connected with the liquid inlet of the chemical reaction sedimentation tank 2, and the output port of the chemical reaction sedimentation tank 2 is connected with the input port of the acid leaching reaction tank 4 through the filter press 3, and the The output port of the acid leaching reaction tank 4 is connected with the liquid collection bin 6 through the filter 5 . Described chemical reaction sedimentation tank 2 is made of pH monitoring and regulating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com