Semi water gas generating system

A generation system, semi-water gas technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of reducing the quality of semi-water gas, increasing compressor power consumption, reducing system production efficiency, etc., to reduce blowing time and increase gas production time , the effect of simple pipeline configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

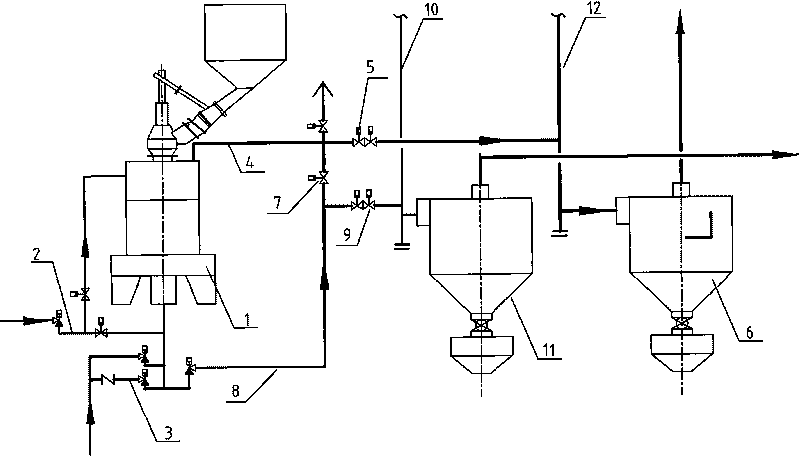

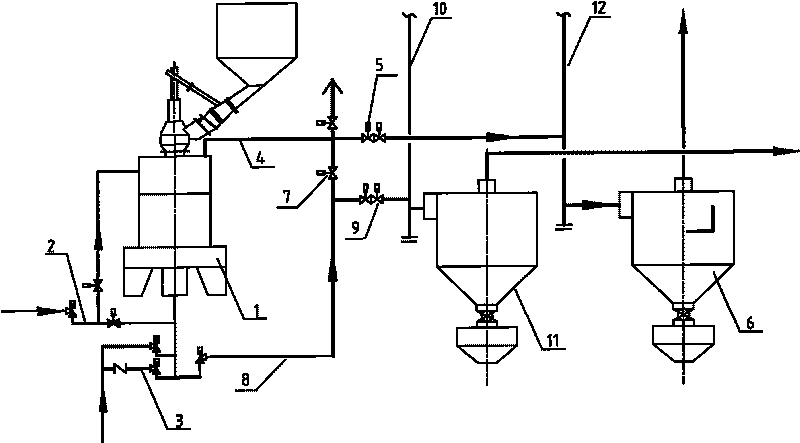

[0013] Such as figure 1 As shown, the present invention comprises a gas furnace 1, a steam pipe 2 and an air inlet pipe 3 are connected to the gas furnace 1, and a plurality of gas furnaces 1 form a single system, and the upstream pipe 4 of the gas furnace 1 passes through the air return valve 5 and the air return valve 5 all the way. Blowing gas main pipe 12 is connected, and blowing gas main pipe 12 is connected with blowing main pipe dust collector 6. The other way of the upward gas pipe 4 of the gas furnace 1 is merged with the upward gas valve 7 and the downward gas pipe 8, and then enters the single-system gas main pipe through the coal main valve 9. 10. The single-system gas main pipe 10 communicates with the gas main pipe dust collector 11. Four gas furnaces 1 form a single system. The upward gas valve 7 and the blowing return valve 5 are delay valves.

[0014] The working principle of the present invention is as follows: steam passes through the steam pipe 2, and ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com