Glass floor

A technology for glass and flooring, applied in floors, coverings/linings, buildings, etc., can solve problems that are not beneficial to human health, can not achieve zero pollution, formaldehyde pollution, etc., and meet different performance requirements and price requirements, with rich patterns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

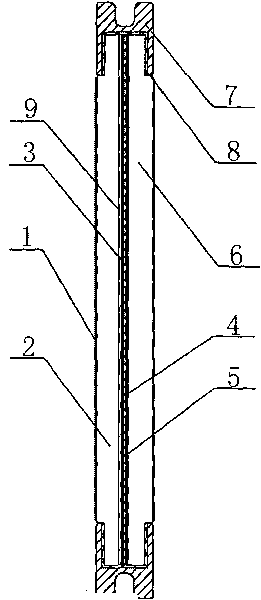

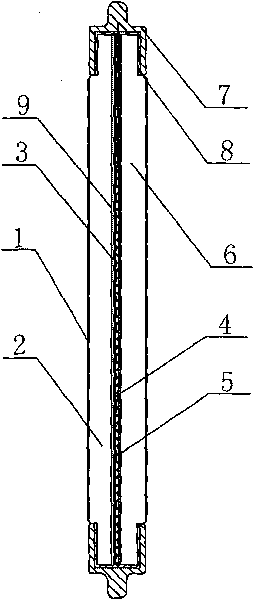

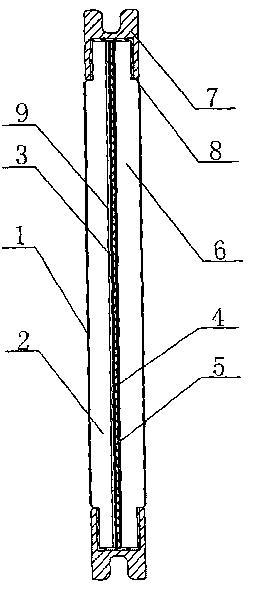

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Depend on figure 1 and figure 2 It can be seen that the glass floor is mainly composed of non-slip decorative surface layer 1, surface layer glass 2, laminated layer 3, decorative middle layer 4, laminated layer 5, base glass 6, tenon buckle 7, and buffer rubber strip 8. , the non-slip decorative surface layer 1 is combined with the surface glass 2 by spraying, printing or bonding, and the surface glass 2, the decorative middle layer 4 and the base glass 6 are combined through the interlayer 3 and the interlayer 5, which is For the main unit, the tenon buckle 7 is assembled around the main unit, and the buffer rubber strip 8 is arranged between the tenon buckle 7 and the main unit.

[0018] Depend on figure 1 It can also be seen that the anti-slip decorative surface layer 1 can also be separately arranged as an anti-slip layer 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com