Boiler with double fire grates and double combustion chambers

A dual-combustion chamber and dual-grate technology, which is used in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of low furnace temperature and difficulty in air supply, and achieve the improvement of furnace temperature and utilization rate. The effect of expanding the range of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

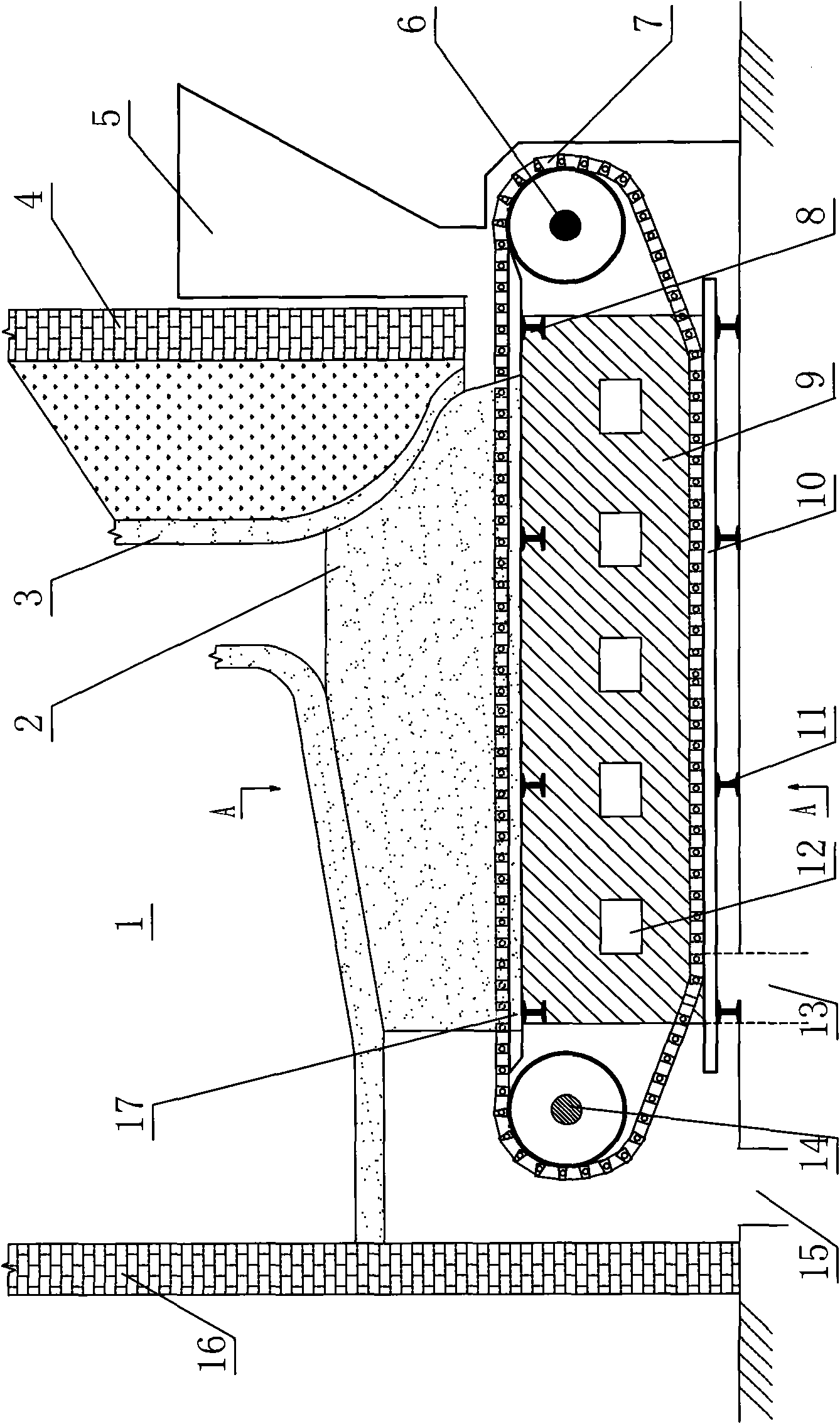

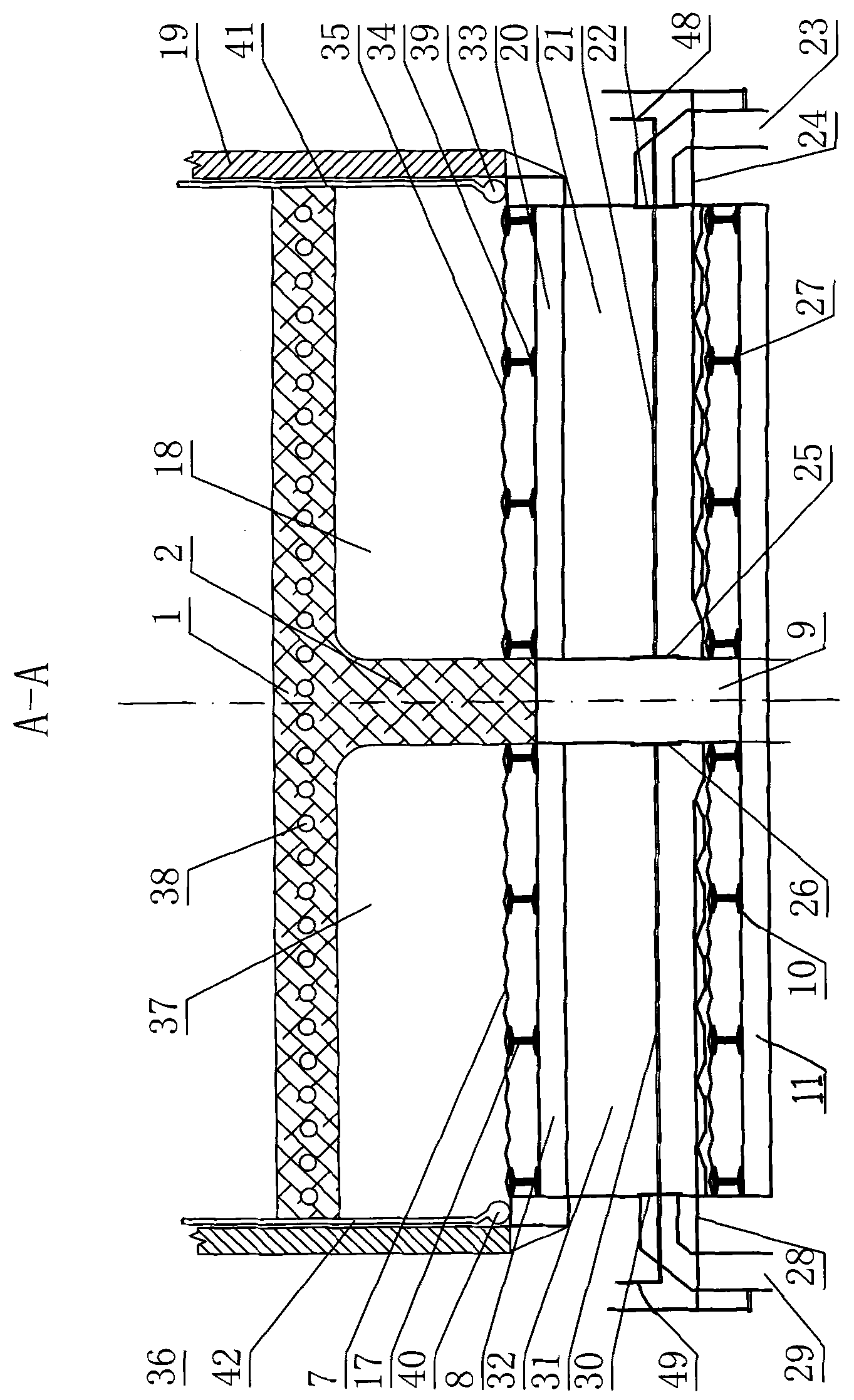

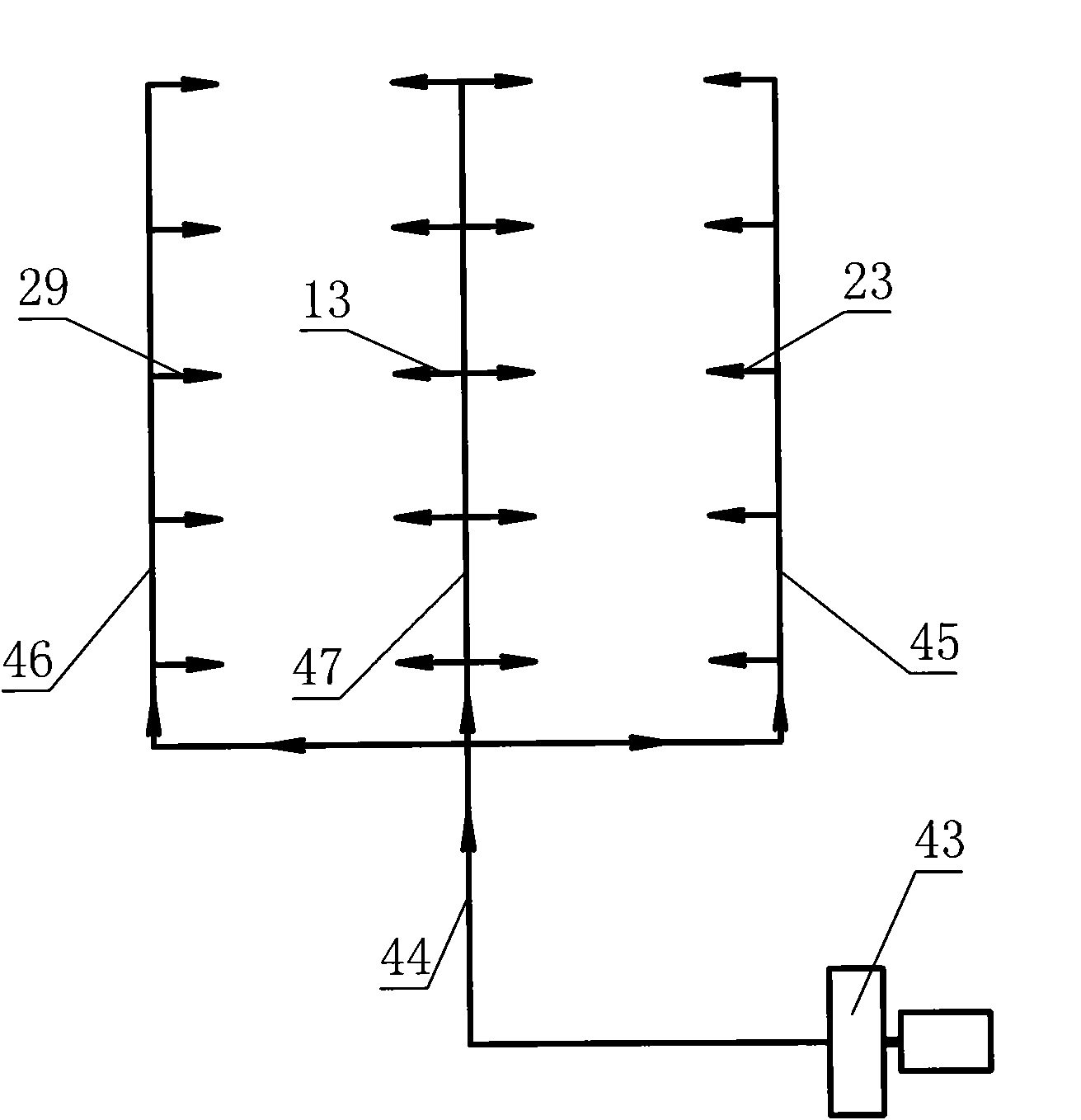

[0015] according to Figure 1~3 The specific structure of the present invention will be described in detail. The present invention reforms the existing coal-fired seam-fired boiler, still including the combustion chamber surrounded by the front furnace wall 4, the rear furnace wall 16, the left furnace wall 36, the right furnace wall 19, the front arch 3, and the rear arch 1, and the combustion chamber The double-layer fire grate driven by the front and rear shafts 6 and 14, the air chambers between the upper and lower layers of the fire grate, and the boiler blower 43 are set under the chamber to keep the boiler shape structure, the fire grate shape and the size of the front and rear shafts 6 , The original state of 14 remains unchanged.

[0016] The upper and lower layers of the fire grate are disconnected in the middle to form the left and right fire grate 7, 35, and the middle bellows 9 is set between the left and right fire grate 7, 35. The left and right sides of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com