Scrap remover of film sticking machine

A film laminating machine and electrode technology, which is applied in the manufacture of ships or lead-in wires, can solve problems such as falling on the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

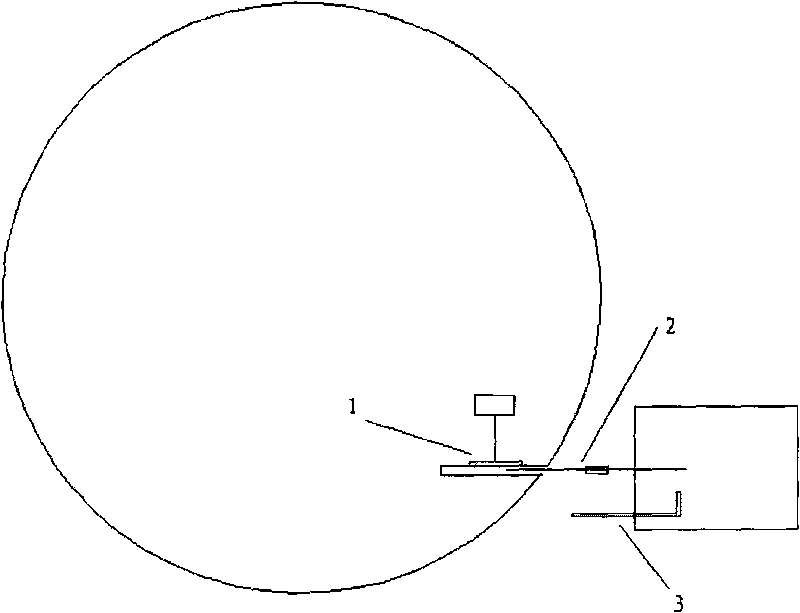

[0014] figure 1 It shows a schematic diagram of a chip removal device for a film laminating machine according to an embodiment of the present invention, including:

[0015] The first electrode 1 is located in the rotary vacuum suction barrel of the film laminating machine;

[0016] a second electrode 3, which is located on the guide rail of the cutting blade 2 of the film applicator, and whose polarity is opposite to that of the first electrode; and

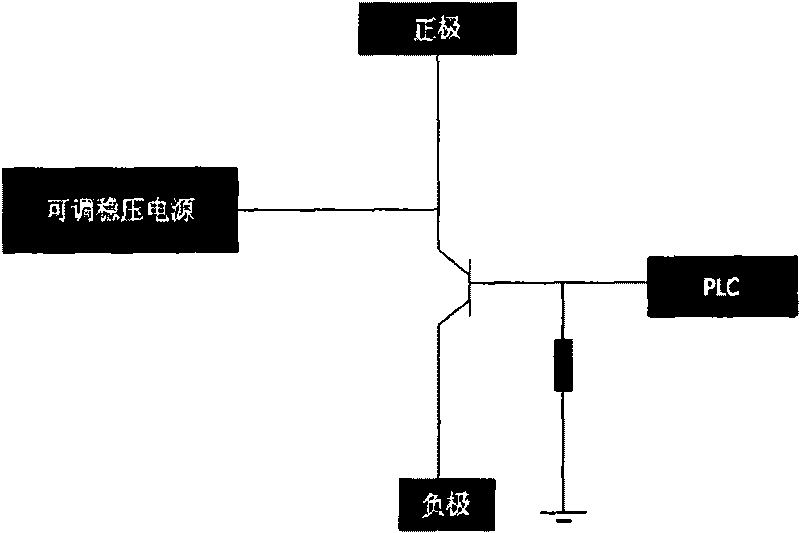

[0017] A power supply (not shown in the figure), which is used to supply power to the first electrode 1 and the second electrode 3 .

[0018] The above-mentioned embodiment forms positive and negative electrodes, and adopts the method of electrostatic attraction, so that the fine chips generated after cutting are adsorbed on the electrodes, so that they will not adhere to the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com