Directional punching shear and processing method for iron core pieces of stator and rotor of rotary motor

A technology of rotating electrical machines and processing methods, which is applied in the manufacture of stator/rotor bodies, etc., and can solve problems such as uneven mold gaps, small punching and shearing forces, and high concentricity of iron chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

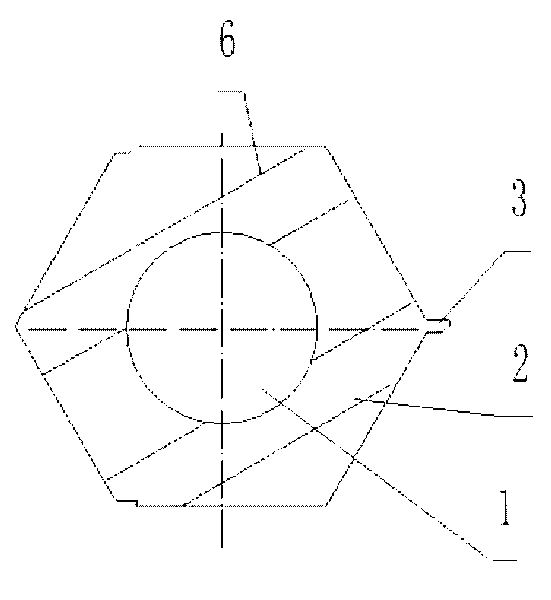

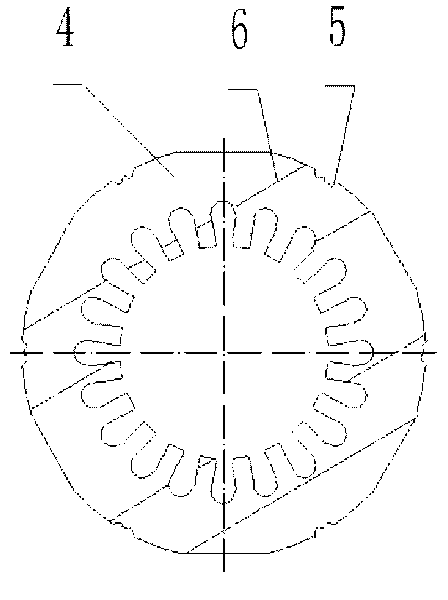

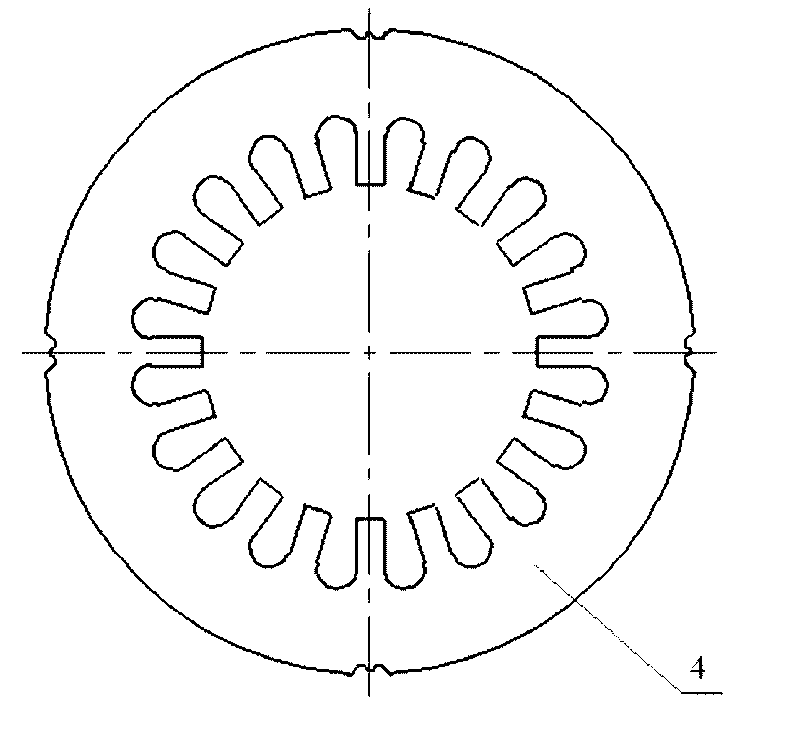

[0023] refer to Figure 1 to Figure 9 , a method for directional punching and shearing processing of stator and rotor core sheets of a rotating electrical machine, characterized in that: firstly, punching an annular blank sheet 2 of the stator core with a rotor mounting through hole 1 in the middle, and the annular blank sheet 2 is provided with The positioning mark 3 of the rotation orientation is used for forming between the annular blank sheet 2 and the punch mold according to the determined rotation orientation during molding, and the positioning mark 3 is used to limit the ring blank sheet 2 and the punch mold when the blank sheet 2 is formed. Rotation orientation between, and limit the rotation orientation of annular blank sheet 2 between annular blank sheet 2 and punching die of stator iron sheet when stator iron sheet 4 is formed simultaneously, on the stator iron sheet 4 of described molding Marks 5 are made for the correct splicing of the stator core sheets of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com