A lithium ion battery negative electrode slurry and a preparation method thereof

A lithium-ion battery and negative electrode slurry technology, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as unstable improvement effects, high equipment performance requirements, and poor appearance of negative electrode sheets, so as to avoid pockmarked appearance Defects, low production cost, and improved coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

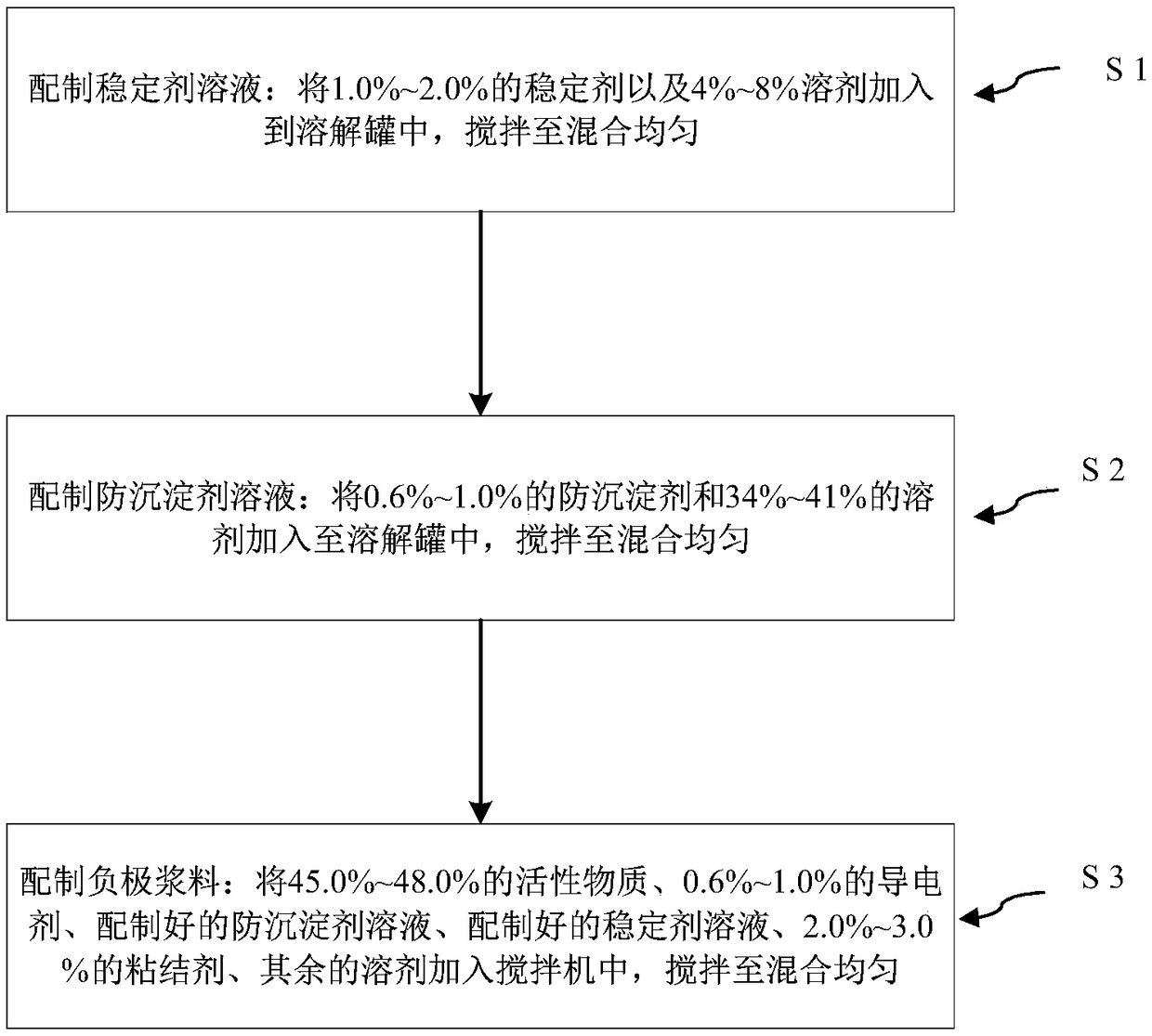

[0080] The preparation method of the lithium ion battery negative electrode slurry of the present embodiment, it comprises the following steps:

[0081] S1. Preparation of stabilizer solution: Add 1.0%-2.0% stabilizer and 4%-8% solvent into the dissolving tank, and stir until evenly mixed.

[0082] Wherein, the stabilizer is ethylene carbonate, and the solvent is deionized water; specifically, the solid ethylene carbonate is placed in a high-temperature room or an oven until the ethylene carbonate is completely dissolved; then the dissolved ethylene carbonate solution is mixed with Add deionized water into the dissolution tank together, set the rotation speed at 30±2 rpm, and stir for 60 minutes to prepare an aqueous solution of ethylene carbonate.

[0083] S2. Prepare anti-precipitation agent solution: add 0.6%-1.0% anti-precipitation agent and 34%-41% solvent into the dissolving tank, stir until mixed evenly.

[0084] Among them, the anti-precipitation agent is sodium hydro...

Embodiment 1

[0109] Ethylene carbonate aqueous solution preparation:

[0110] Place the solid ethylene carbonate in a high-temperature room or oven, set the baking temperature at 50±5°C until the ethylene carbonate is completely dissolved; take 3.0Kg of dissolved ethylene carbonate liquid and 12.0Kg of deionized water into 30L for dissolution In the tank, set the rotation speed at 30±2rpm, and stir for 60min to obtain an aqueous solution of ethylene carbonate;

[0111] WSC-C solution preparation:

[0112] Add 1.5Kg of WSC-C powder and 81.83Kg of deionized water into a 100L dissolution tank, set the rotation speed at 30±2rpm, and stir for 360min to prepare the WSC-C solution;

[0113] Negative electrode slurry preparation:

[0114] Add 94Kg graphite (FSNC-1) and 2.0Kg Super-P into the 350L mixer, set the revolution to 30±2rpm, the rotation to 200±20rpm, and stir for 30min; Revolution 30±2rpm, autorotation 200±20rpm, stir for 120min; after stirring, add 32.50Kg WSC-C solution, 15.0Kg ethy...

Embodiment 2

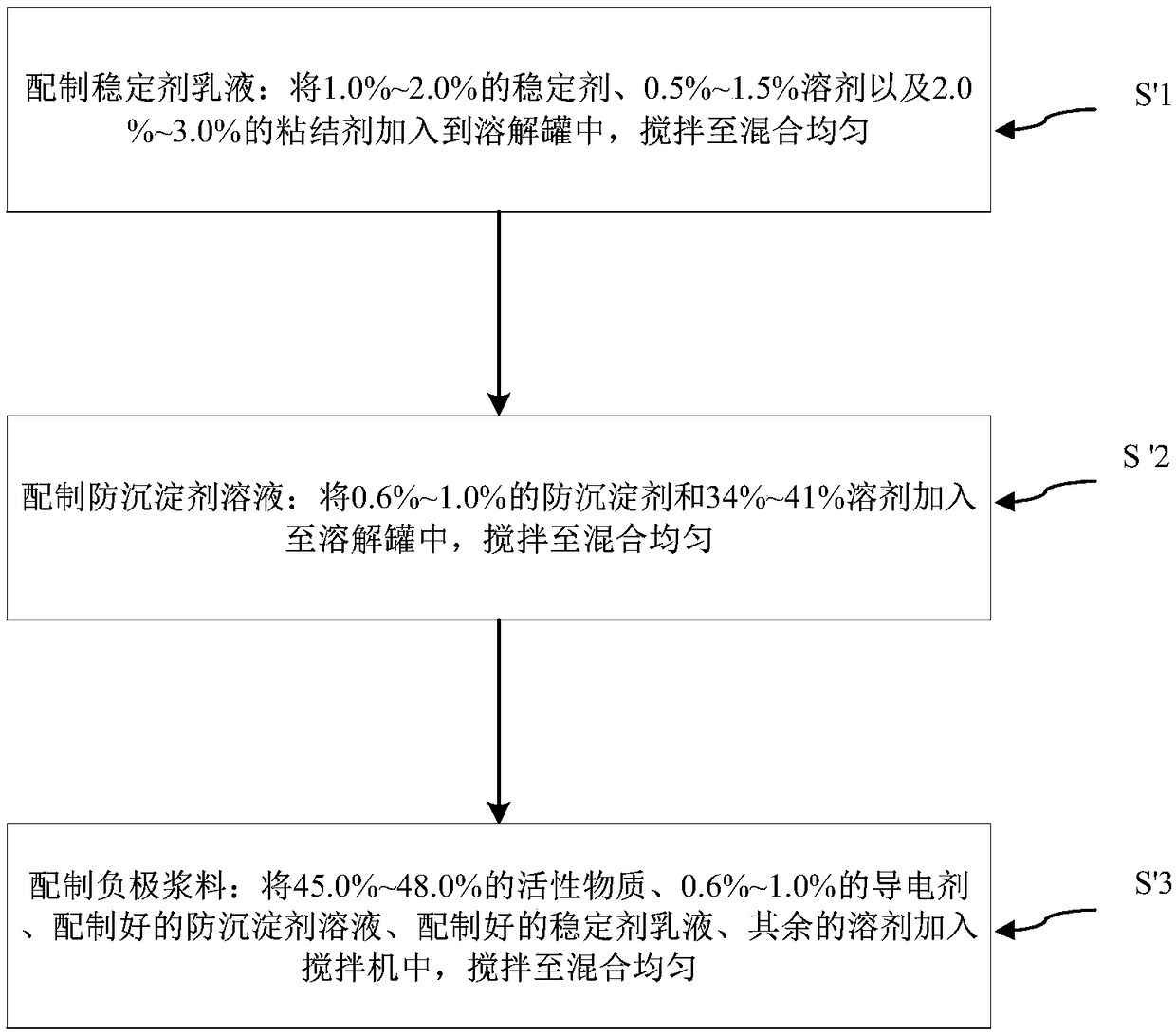

[0116] Preparation of Ethylene Carbonate SBR Emulsion:

[0117] Place the solid ethylene carbonate in a high-temperature room or oven, set the baking temperature at 50±5°C until the ethylene carbonate is completely dissolved; take 3.0Kg of the dissolved ethylene carbonate liquid, 5.0Kg of styrene-butadiene rubber emulsion and deionized Add 2.0Kg of water into a 15L dissolving tank, set the speed at 30±2rpm, and stir for 60min to prepare ethylene carbonate styrene-butadiene rubber emulsion;

[0118] WSC-C solution preparation:

[0119] Add 1.5Kg of WSC-C powder and 81.83Kg of deionized water into a 100L dissolution tank, set the rotation speed at 30±2rpm, and stir for 360min to prepare the WSC-C solution;

[0120] Negative electrode slurry preparation:

[0121] Add 94.50Kg of graphite (AML-400) and 1.50Kg of Super-P into a 350L dissolving tank, set the revolution at 30±2rpm, rotate at 200±20rpm, and stir for 30min; after stirring, add 50.83K WSC-C solution into the mixer , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com