Multifunction windrower

A windrower and multi-functional technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increasing the production cost of the whole machine, poor linkage, poor reliability of steering operation, etc., and achieve a simple and compact header structure , reduce production costs, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

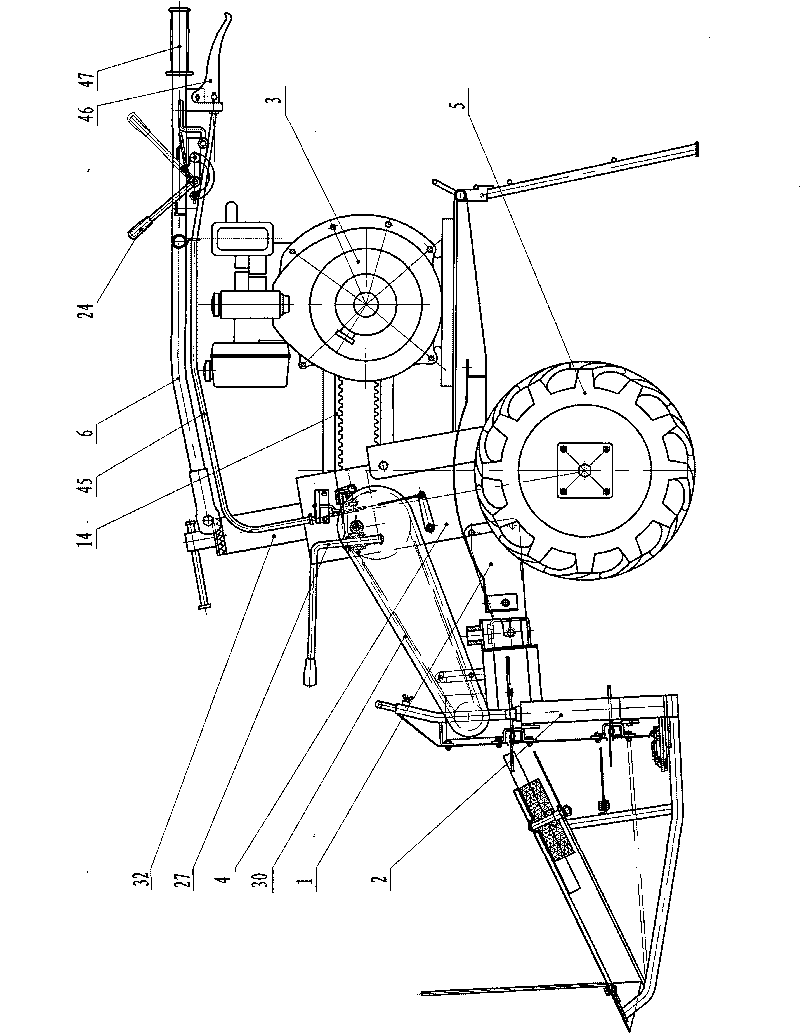

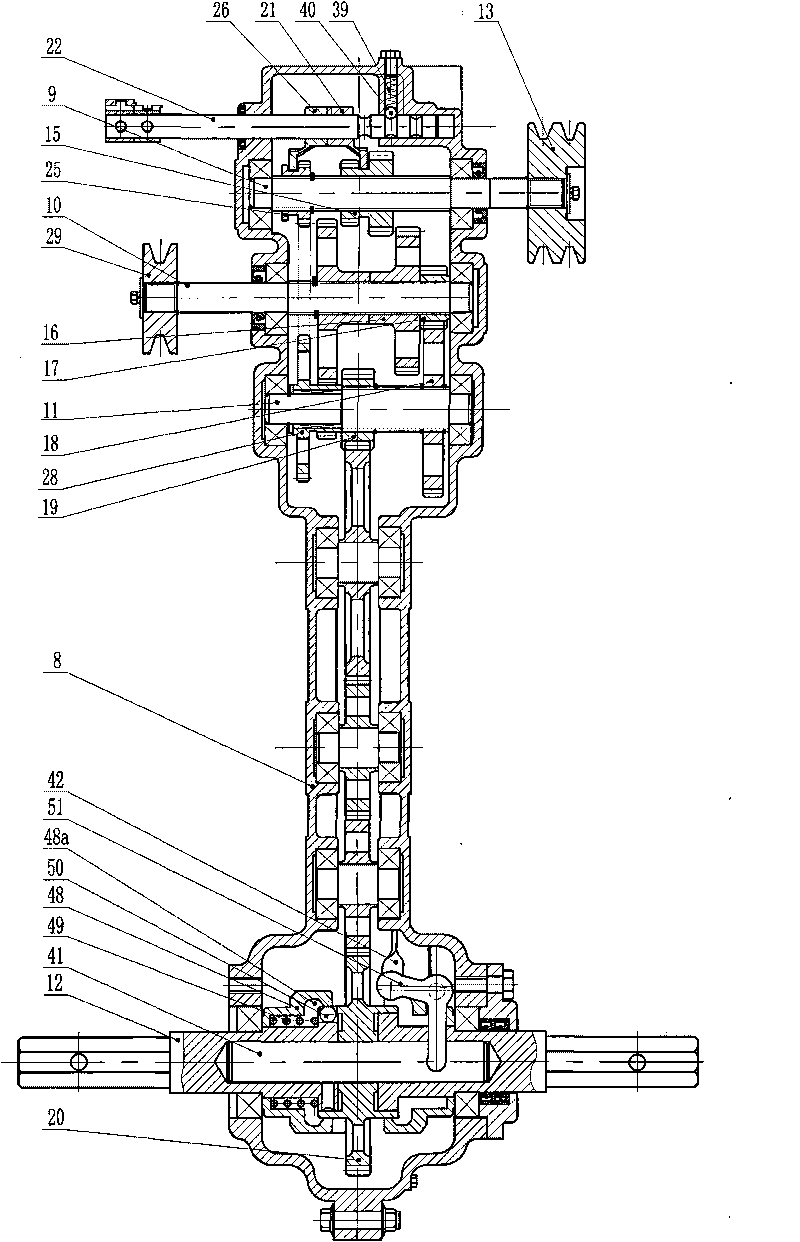

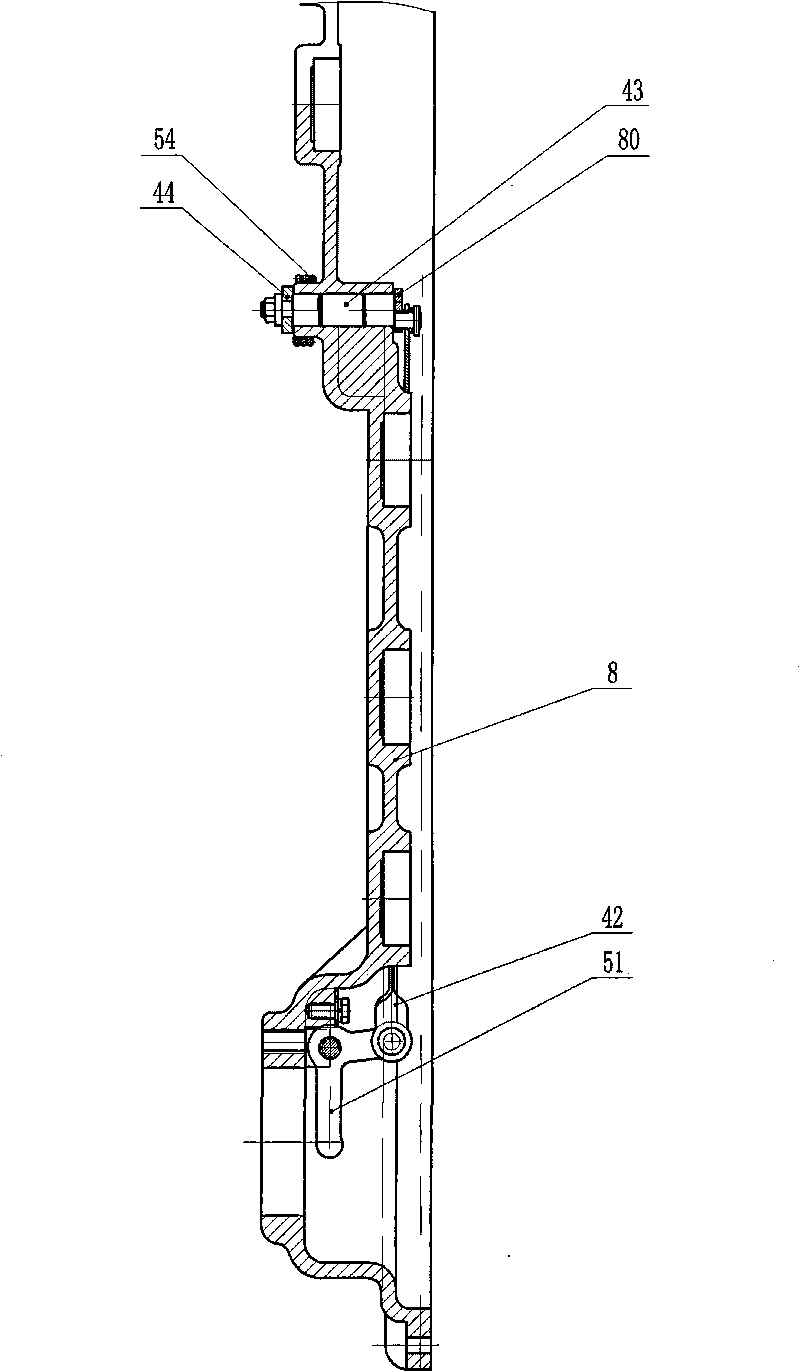

[0043] Such as figure 1 , Figure 6 , Figure 7 , Figure 8 As shown, the header 2 is detachably installed at the front end of the frame 1, the rear end of the frame 1 is fixedly supporting the engine 3, and the middle part of the frame 1 is equipped with a gearbox 4. Fix the armrest seat 32 on the top of the casing 8 of the gearbox 4, the top of the armrest seat 32 is welded with the first grinding disc tooth 33, and the center of the first grinding disc tooth 33 is fixedly pierced with the first bolt 34 from bottom to top. The upper end of a bolt 34 extends into the first positioning sleeve 35 and is locked by a nut provided inside the first positioning sleeve 35 . A second grinding wheel tooth 36 is arranged at the bottom of the first positioning sleeve 35 , and the second grinding wheel tooth 36 meshes with the first grinding wheel tooth 33 . A first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com