Dust collector collision board based on fulcrum conversion

A collision plate and vacuum cleaner technology, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc., can solve problems such as failure to provide restoring force, jamming, and failure to provide vertical displacement, so as to improve flexibility and sensitivity and reduce friction power, improved reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

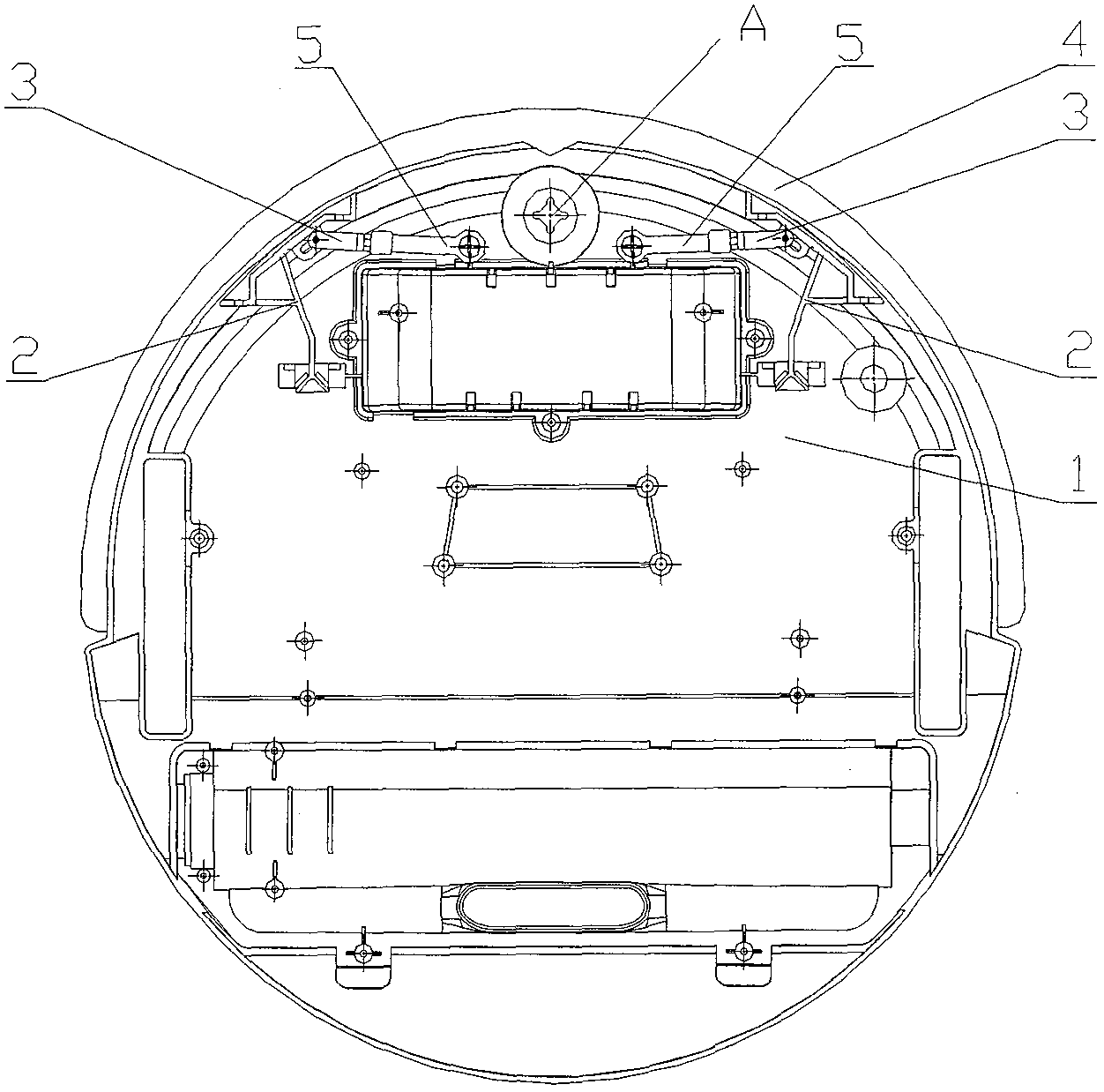

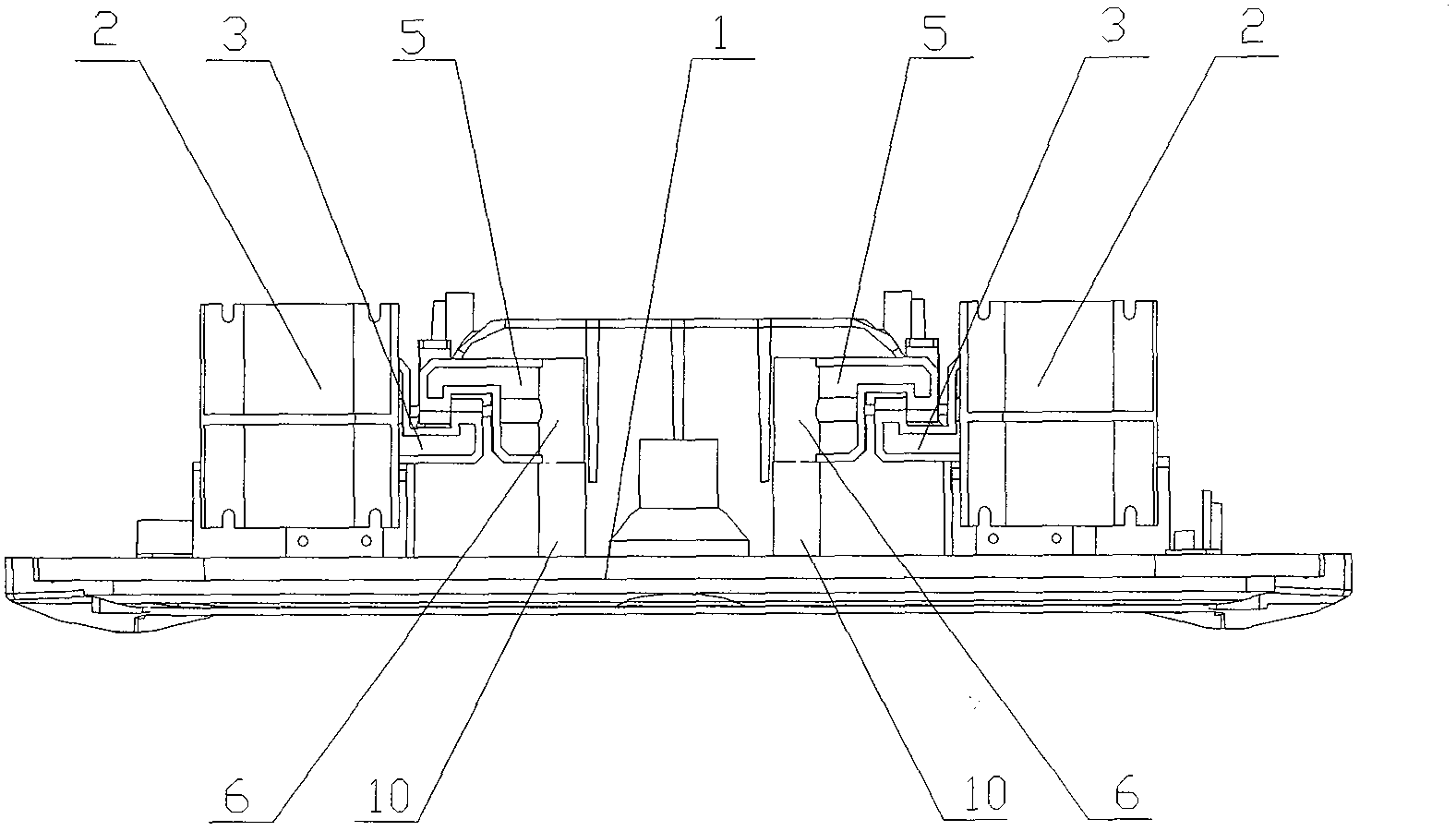

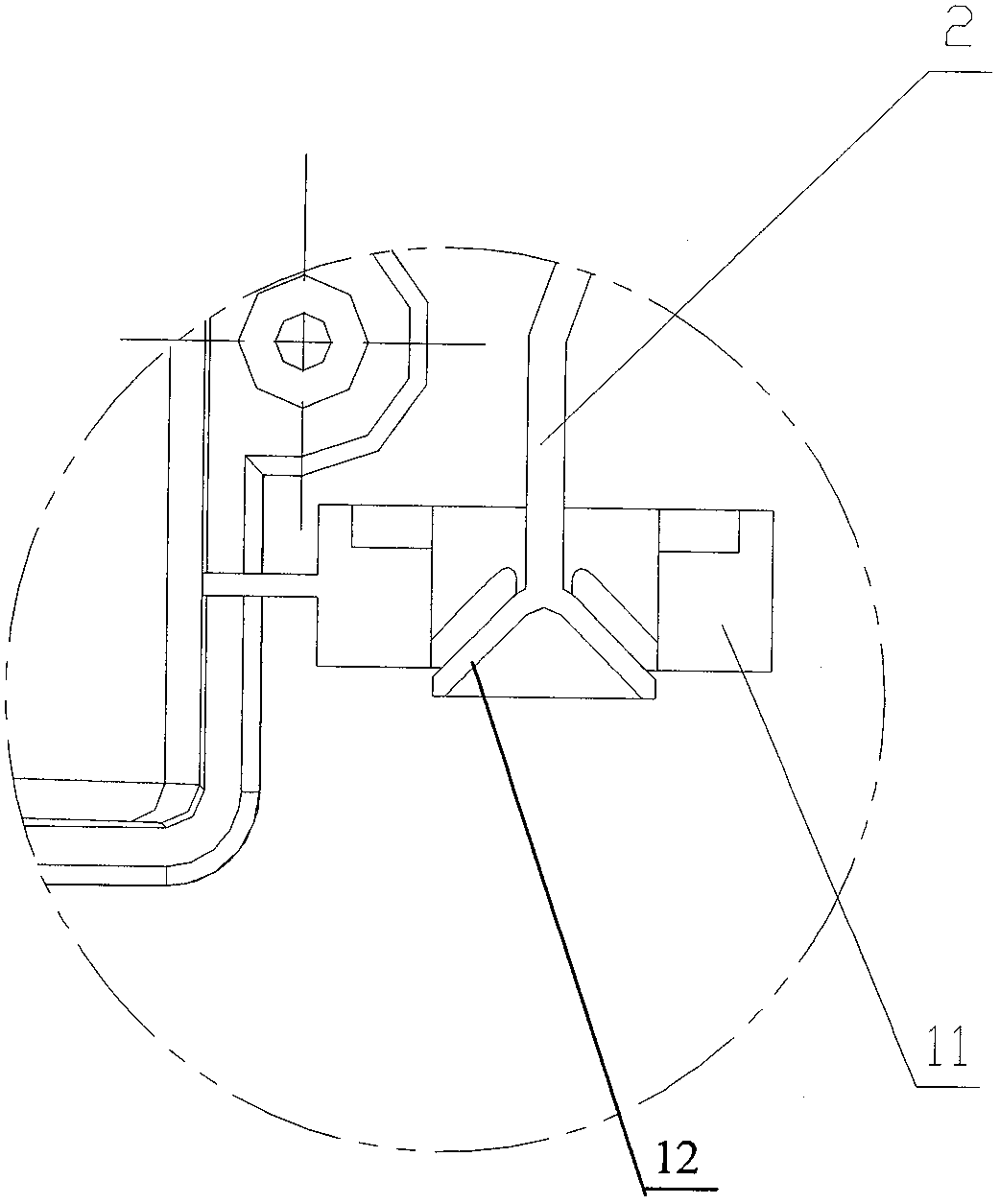

[0020] The vacuum cleaner collision plate based on fulcrum transformation of the present invention includes a collision plate main body, a support bar, a sliding link, a hinge link, a cylindrical pin, a tapered pin, a V-shaped support block, a torsion spring and a vacuum cleaner chassis. The main body of the collision plate is supported on the chassis by 4 fulcrums, two of which are formed by the contact between the V-shaped structure at the end of the support bar and the V-shaped support block; the cylindrical shaft on the hinge rod is matched with the round hole on the chassis The connection forms the other two fulcrums. The main body of the collision plate can flexibly move up and down, left and right around these four fulcrums, and can be connected with the chassis by sliding with multiple degrees of freedom. The back-moving spring is a torsion spring, which is installed on both sides of the chassis, one end is fixed with the upper cover, and the other end is obliquely pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com