Environmental humidity control method and device for sealed cavity

A technology of environmental humidity and control method, applied in the direction of humidity control, non-electric variable control, control/regulation system, etc., can solve the problem of not being able to accurately control the humidity, etc., achieve fast humidity regulation speed, wide regulation humidity range, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below with the mode of embodiment:

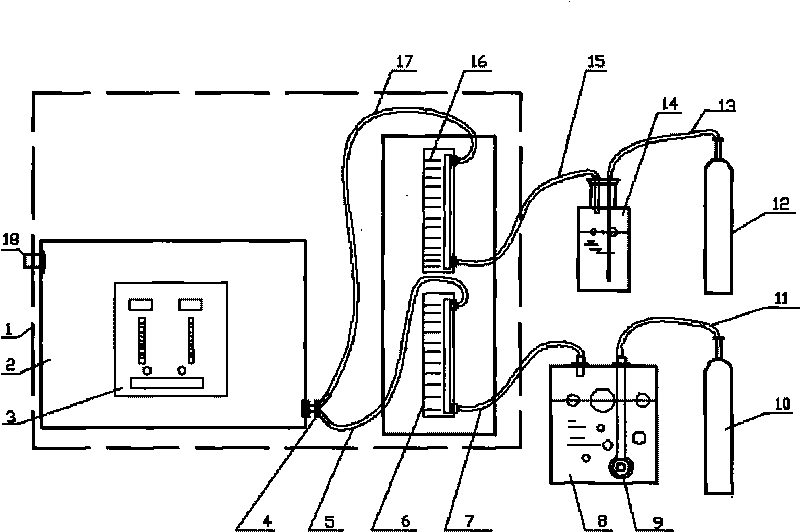

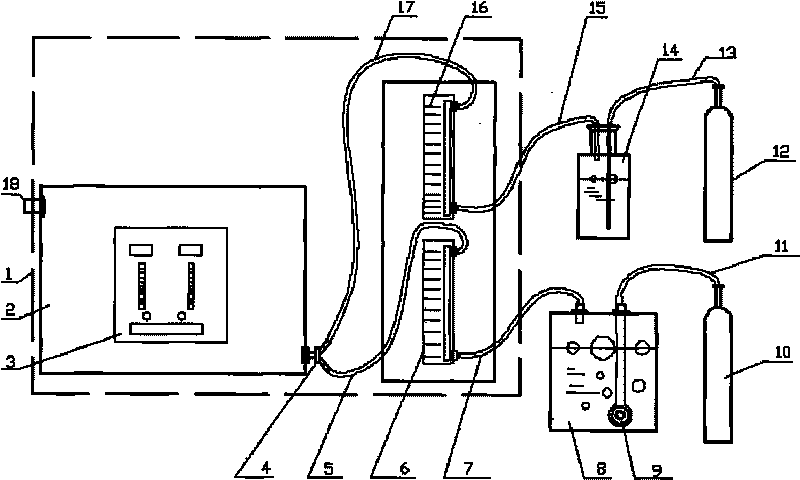

[0012] The gas is divided into two branches of drying and humidification and enters the air chamber of the airtight cavity. Use high-pressure gas cylinders or gas compressors to adjust the required test gas to the specified pressure to ensure that the pressure of the gas source is stable, thereby providing a basic guarantee for accurate humidity control. Among them, the dry gas branch passes concentrated H 2 SO 4 After drying, it is regulated by the gas flow meter and then connected to the three-way gas joint; the humidified gas branch is humidified through the water tank and then connected to the three-way gas joint after being regulated by the flow meter. Cavity environment air chamber. The humidity control in the air chamber of the airtight chamber ring chamber is adjusted by adjusting the flow rate ratio of dry and wet gas through two flowmeters. Gas source components can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com