Novel steel bar group of cathode block

A technology of cathode carbon block and cathode steel rod, which is applied in the field of new cathode carbon block and steel rod group, which can solve the problems of high pressure drop value and large resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

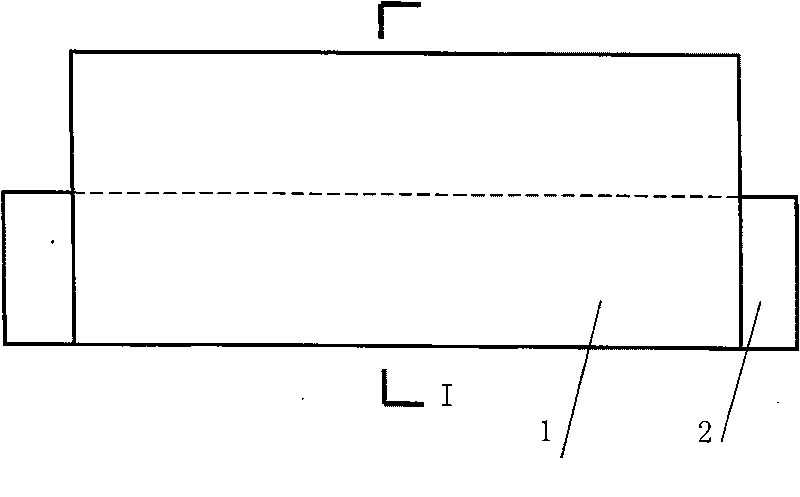

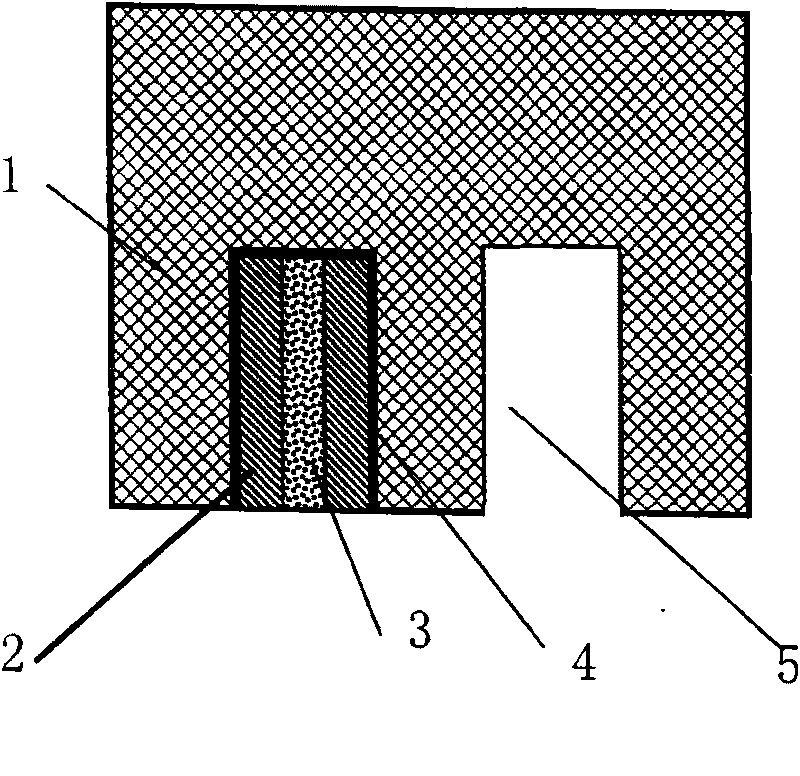

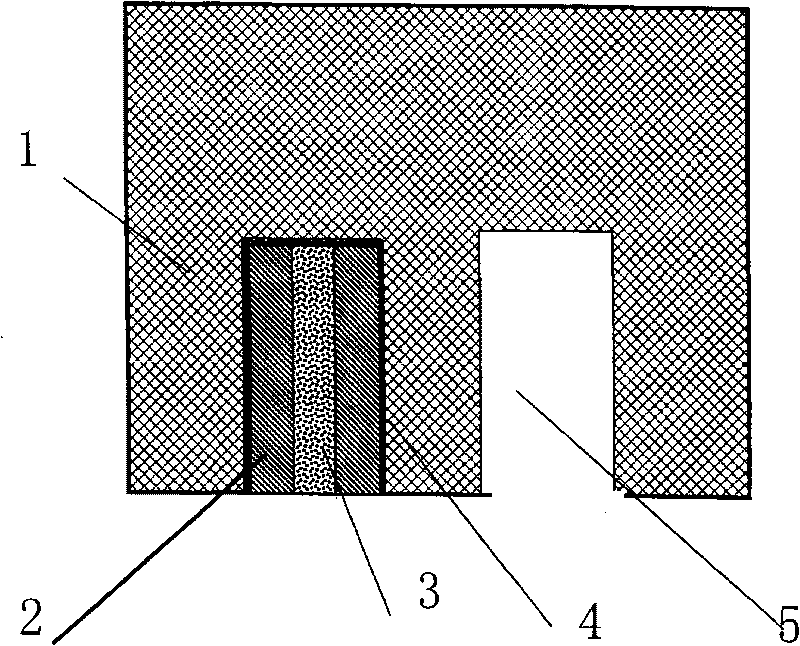

[0012] The technical scheme of a new type of cathode carbon block steel rod group is shown in the attached drawing figure 1 , figure 2 Shown, the biggest difference with existing common cathode carbon block steel rod group is that only a cathode steel rod (2) was set in the past in the same cathode carbon block (1) steel rod groove (5), and steel rod (2) two There are steel rods tamping paste (3) on both sides, which are connected with the cathode carbon block (1). And what new technology scheme adopted is two cathode steel rods (2), there is steel rod tamping paste (3) in the middle of two steel rods (2), and what the outer surface of two cathode steel rods (2) adopts high temperature resistant The conductive glue (4) is connected with the cathode carbon block (1).

[0013] The conductive glue (4) between iron and carbon must have high temperature resistance. Usually, resin is used as a bonding agent, graphite powder or boron carbide powder is used as aggregate, and it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com