Portable ultraphonic phased array detection imager

An ultrasonic phased array, portable technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of complicated operation and inconvenient use, and achieve the effect of strong engineering applicability and natural human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

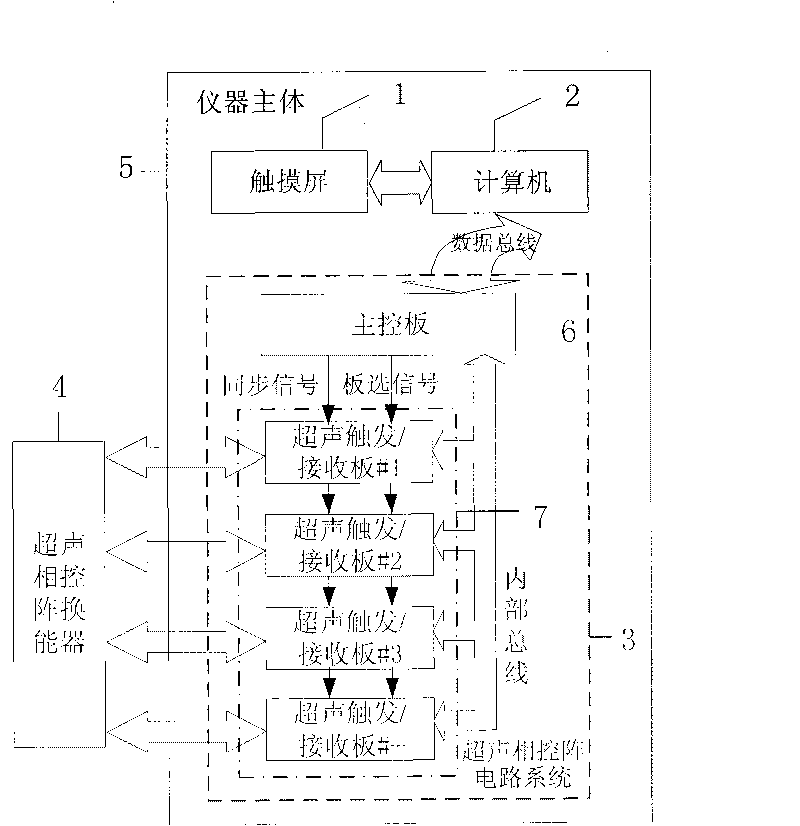

[0018] Example 1: Combining figure 1 , the portable ultrasonic phased array detection imager of the present invention, it is made up of touch screen (1), computer (2), ultrasonic phased array circuit system (3) and ultrasonic phased array probe (4) and detection imaging software. The touch screen (1) is connected to the computer (2), the computer (2) is connected to the ultrasonic phased array circuit system (3) through the data bus, and the touch screen (1), the computer (2) and the ultrasonic phased array circuit system (3) are integrated One body, constituting the main body (5) of the instrument, the ultrasonic phased array probe (4) is externally connected through the cable, and the detection and imaging software is installed on the computer.

[0019] The present invention also has the following technical characteristics:

[0020] The ultrasonic phased array probe (4) is composed of a multi-chip array element group, which is a linear array transducer or a phased array tra...

Embodiment 2

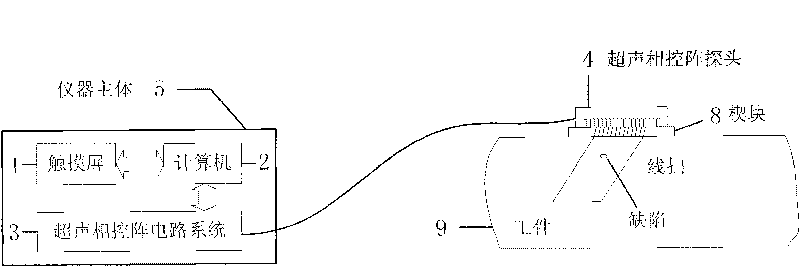

[0025] combine figure 2 , The invention is composed of a touch screen (1), a computer (2), an ultrasonic phased array circuit system (3), an ultrasonic phased array probe (4) and detection and imaging software. Wherein the touch screen (1), the computer (2) and the ultrasonic phased array circuit system (3) are integrated to form an instrument main body (5), and the ultrasonic phased array probe (4) is externally connected.

[0026] In this implementation, an ultrasonic linear array probe with a working frequency of 2.25MHz and 64 elements is connected to the instrument. The performance of the ultrasonic phased array circuit system is shown in Table 1. It consists of a main control board and two ultrasonic trigger / receiver boards. Each ultrasonic trigger / receiver board can realize the triggering of 8-channel signals and the collection of echo signals. . In the system, every 4 phased array elements share a signal processing channel through switching control.

[0027] Table ...

Embodiment 3

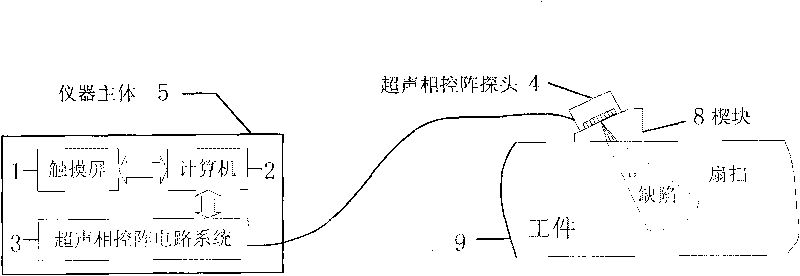

[0031] combine image 3 In this embodiment, the ultrasonic phased array probe (4) with a working frequency of 5 MHz and 32 array elements is connected to the instrument. The performance of the ultrasonic phased array circuit system (3) is shown in Table 2. It consists of a main control board and four ultrasonic triggering / receiving boards. Each ultrasonic triggering / receiving board can realize the triggering and echoing of 8-channel signals. signal collection. In the system, every two phased array elements share a signal processing channel through switching control.

[0032] Table 2 Performance parameters of the circuit system of Embodiment 3

[0033]

[0034] combine image 3 , due to the use of shear waves to detect defects in the workpiece, the probe is installed on the wedge 8 for wave mode conversion, and coupled with the workpiece (9) with a couplant. In this embodiment, the flaw detector manually operates the ultrasonic phased array probe (4) on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com