Method for manufacturing liquid crystal display panel

A technology for liquid crystal display panels and manufacturing methods, which is applied to the photoplate-making process of patterned surfaces, optics, and optomechanical equipment, etc., and can solve problems such as color shift, multi-domain vertical alignment type liquid crystal display panel picture brightness changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

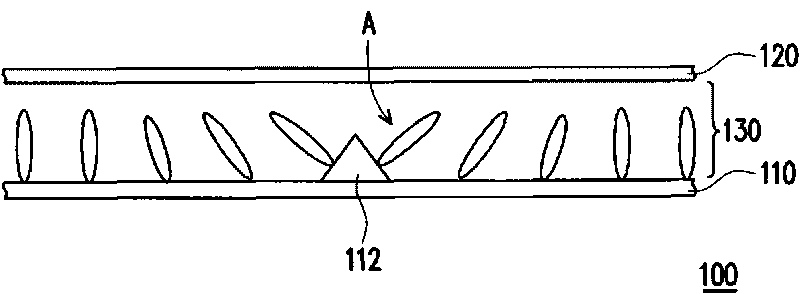

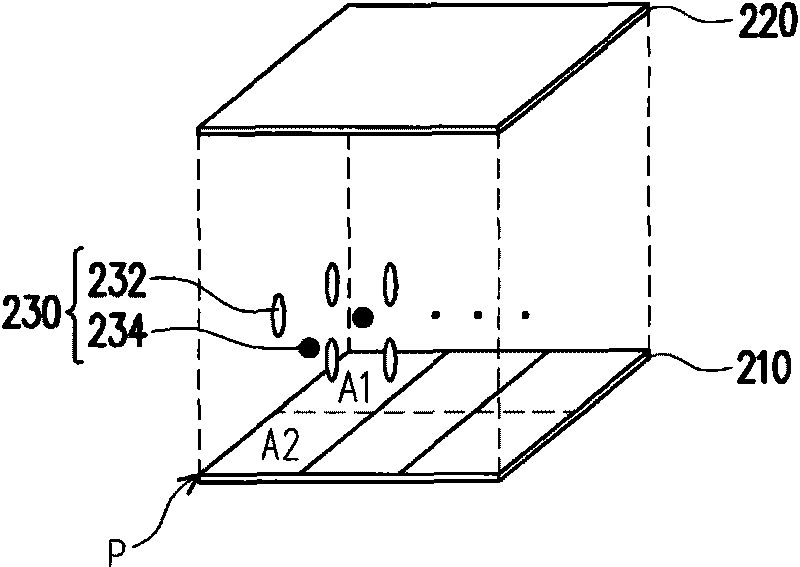

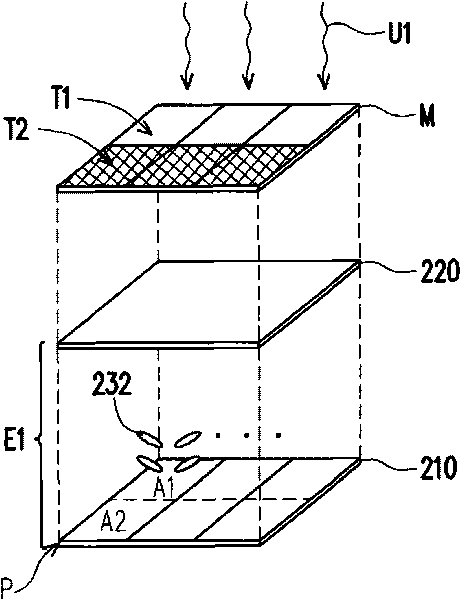

[0038] Figure 2A-2C It is a schematic flow chart of the manufacturing method of the liquid crystal display panel according to the first embodiment of the present invention. Please refer to Figure 2A Firstly, a first substrate 210 and a second substrate 220 are provided. Wherein the first substrate 210 has a plurality of pixels P. As shown in FIG. In particular, each pixel P can be divided into a first area A1 and a second area A2, Figure 2A are shown as two regions, but not limited thereto). In other embodiments, each pixel P can be divided into more than two regions, such as three, four or more regions. In practice, the first substrate 210 is, for example, an active device array substrate, and the second substrate 220 is a color filter substrate. In other embodiments, the first substrate 210 can also be an active device array substrate (manufactured by COA technology) with a color filter layer, and the second substrate 220 is a transparent substrate with a shared elec...

no. 2 example

[0044] The second embodiment is similar to the first embodiment, and the similarities will not be repeated here. The main difference between the two is: the position of the mask during the exposure process. Figure 4A is the position of the photomask in the first light irradiation step in the second embodiment of the present invention. Such as Figure 4A As shown, the photomask M may be located under the first substrate 210 for exposure. Wherein, the light-transmitting area T1 of the mask M corresponds to the first area A1.

[0045] Figure 4B is the position of the photomask in the second light irradiation step of the second embodiment of the present invention. Please refer to Figure 4B , the mask M is located above the first substrate 210 . Wherein, the light-transmitting area T1 of the mask M corresponds to the second area A2. This also enables the first light irradiation step and the second light irradiation step to proceed smoothly, so that the liquid crystal mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com