Optical fiber wire core-implanted transposition conducting wire

A technology of transposed wires and optical fibers, applied in the direction of transformer/inductor coil/winding/connection, electrical components, circuits, etc., can solve the problems of repeated equipment investment and load waste, lack of detection transformers, sudden power failure society, etc. Simple structure, excellent mechanical strength, and the effect of increasing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

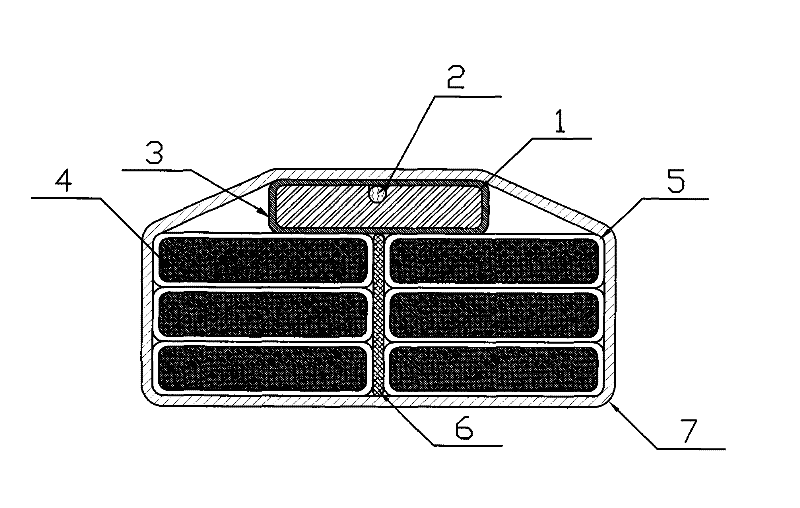

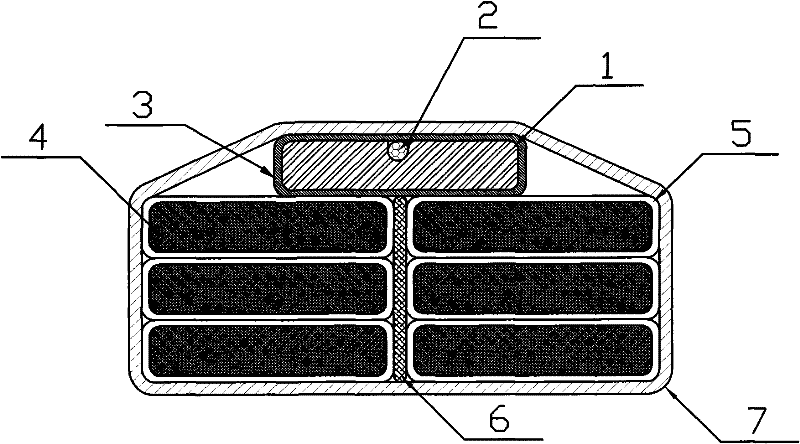

[0010] Such as figure 1 As shown, including slotted special-shaped copper flat wire 1, optical fiber core 2, film sintered wrapping insulation layer 3, oxygen-free copper flat wire 4, insulating varnish layer 5, isolated cable paper 6, high-density insulating paper wrapping layer 7.

[0011] The optical fiber core 2 of the present invention is embedded in the slotted special-shaped copper flat wire 1 slot; the film sintered wrapping insulating layer 3 is coated with 46 The adhesive film is wrapped and sintered by high-frequency induction heating equipment, and the film is closely attached to the surface of the slotted special-shaped copper flat wire 1 implanted in the optical fiber core 2 to make a thin film sintered copper flat wire implanted in the optical fiber core. The insulating varnish layer 5 is coated with insulating varnish on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com