Oil evacuation and nitrogen injection control device of oil-immersed transformer

A technology of oil-immersed transformers, oil discharge and nitrogen injection, which is applied in transformer/inductor cooling, program control, computer control, etc., can solve the problem of inability to realize information management and remote monitoring and operation, being easily affected by environmental temperature changes, It is not convenient for equipment maintenance and accountability, and achieves the effect of facilitating program modification and supplementary functions, improving reliability and maintainability, and facilitating archiving and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

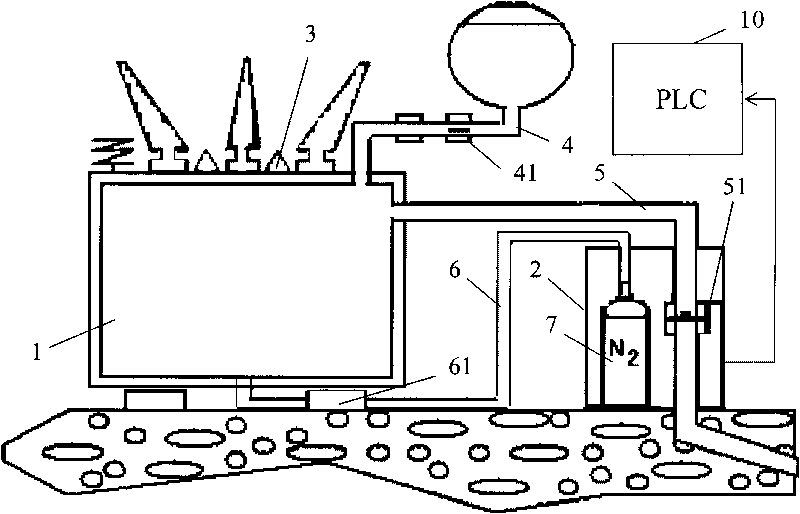

[0029] Such as figure 1 Shown is a schematic structural view of the first embodiment of the oil discharge and nitrogen injection control device of the present invention, which includes: an on-site detector 3, an oil drain valve 51, a shut-off valve 41 and a nitrogen inlet valve 61, and the on-site detector 3 is set On the oil-immersed transformer 1, the oil drain valve 51 is arranged on the oil discharge pipeline 5, the shut-off valve 41 is arranged on the oil inlet pipeline 4, and the nitrogen inlet valve 61 is arranged on the nitrogen inlet pipeline 6. 3 The detected signal controls the PLC (programmable logic controller) 10 for the action of the oil drain valve 51, the shut-off valve 41 and the nitrogen inlet valve 61, the on-site detector 3, the oil drain valve 51, the shut-off valve 41 and the nitrogen inlet valve The valve 61 is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com