Method for on-site manufacturing low-voltage branch cable head

A technology for on-site production and branch cables, which is applied to the equipment for connecting/terminating cables, and the connection and connection are completed by deformation. It can solve the problems of inaccurate positioning, deviation of installation position, waste of branch cables, etc., to improve moisture resistance. , The effect of high insulation strength and flexible installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below according to the drawings and specific embodiments.

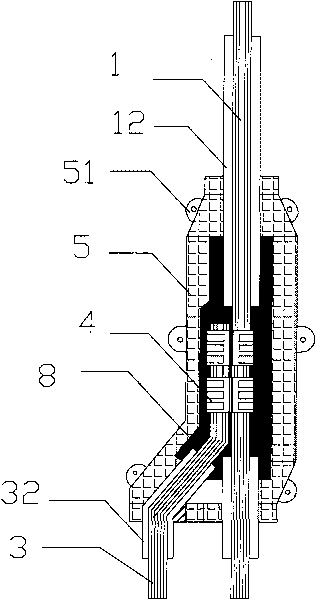

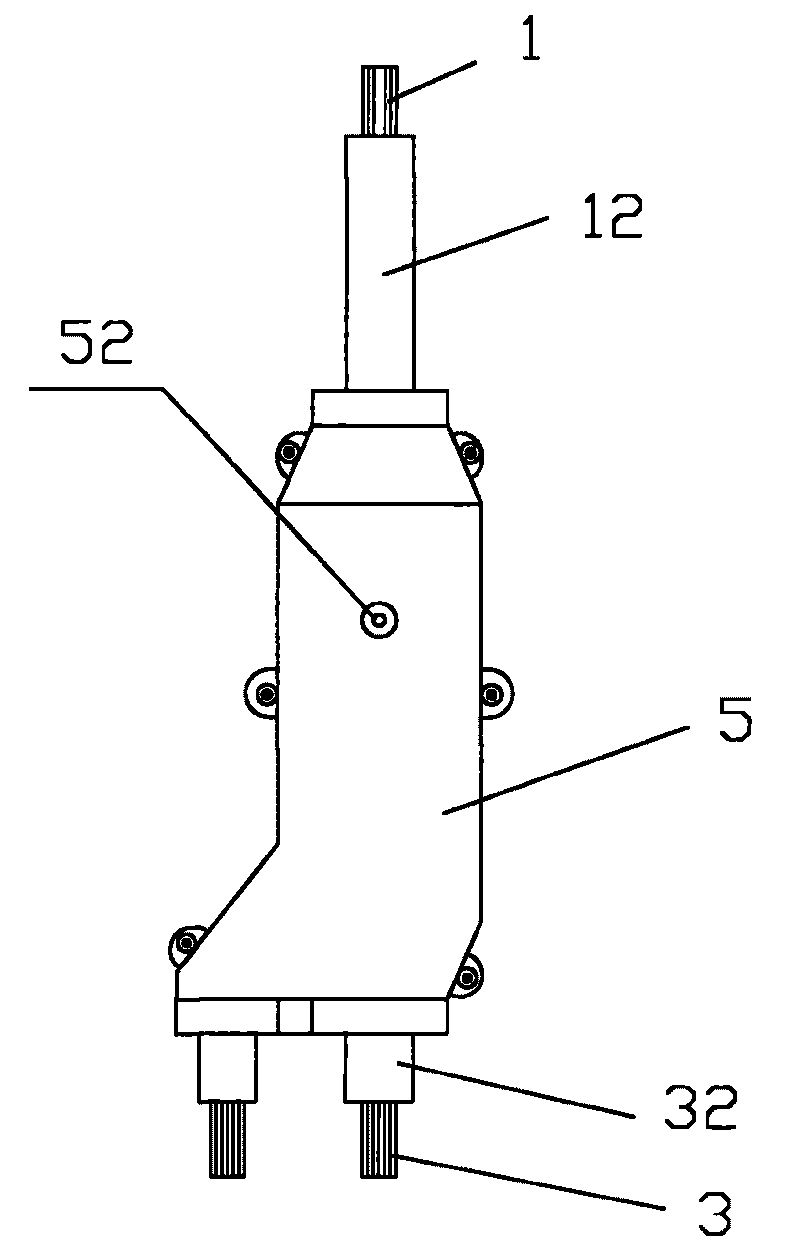

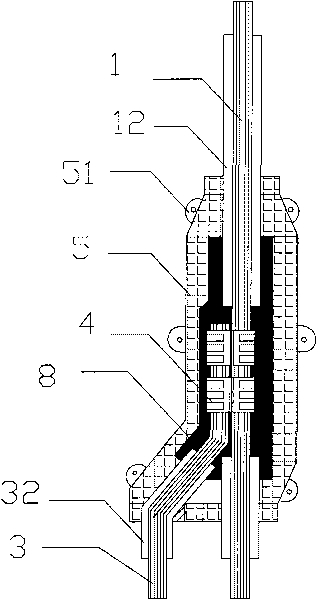

[0017] like figure 1 and figure 2 Shown, a kind of method of making low-voltage branch cable head on the spot of the present invention comprises the following steps: one, remove insulation sheath: remove insulation sheath 12,32 at main cable 1 needs branch and the end of branch cable 3; Two, Connect the main cable 1 and the branch cable 3 at the joint: use the branch C-shaped connection clamp 4 to crimp and fix the main cable 1 and the branch cable 3 at the joint; Two separate PVC injection-molded branch covers 5 are covered, and the joints 51 of the two branch covers 5 are fixed by screws; 4. The mixture 8 of room temperature vulcanized silicone rubber on-site and coupling agent is matched with a pressure injection tool Inject into the mold cavity that is made up of two branch covers 5 through the injection port 52 on the branch cover 5, and form insulation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com