Coupling layer and printed circuit board with same

A technology of printed circuit board and coupling layer, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problems of large area of printed circuit board, small area of power layer 20 can not meet the design requirements, etc., to suppress electromagnetic radiation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

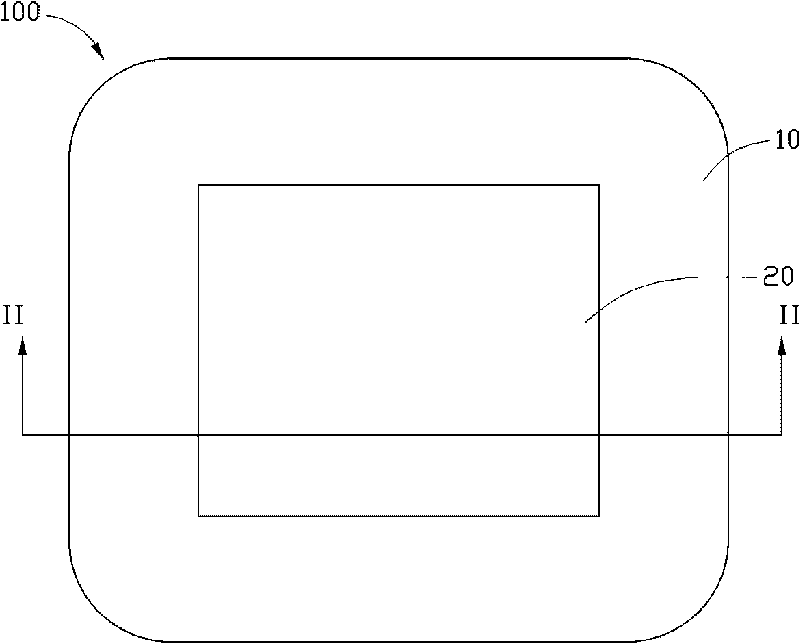

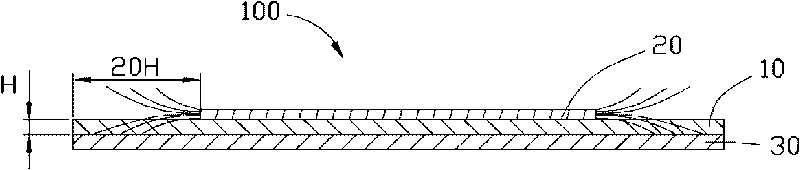

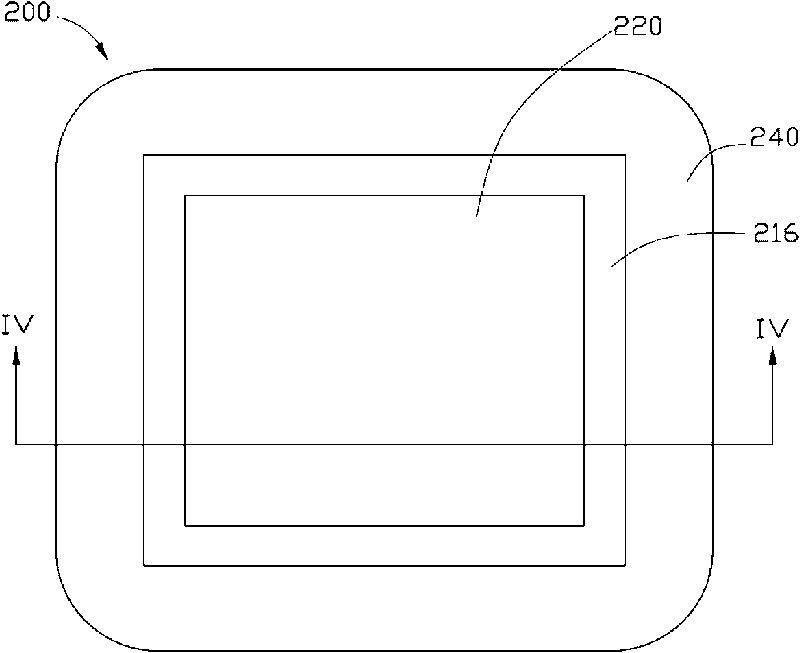

[0014] combine image 3 and Figure 4 , the present invention provides a coupling layer 200 for a printed circuit board, which includes: a first dielectric layer 210 , a power layer 220 and a ground layer 230 . The first dielectric layer 210 includes a first surface 212 and a second surface 214 opposite to the first surface 212 . The power layer 220 and the ground layer 230 cover the first surface 212 and the second surface 214 respectively. The thickness of the first dielectric layer 210 is H. On the first surface 212 , the power layer 220 is indented a distance from the ground layer 230 to form a bare area 216 . Preferably, the distance is selected as 20H. It can be understood that the distance can also be greater than 20H. The coupling layer 200 also includes a via hole 250 . The exposed area 216 is covered with a conductive layer 240 insulated from the power layer 220 , and the conductive layer 240 is electrically connected to the ground layer 230 through the via hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com