Suction cleaner

A technology of vacuum cleaners and filters, applied in the directions of vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of not being able to cool the motor and circuit board, affecting normal use, and easy to heat the motor and circuit board, so as to prolong the service life and avoid Simple and reasonable structure of overheating and air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

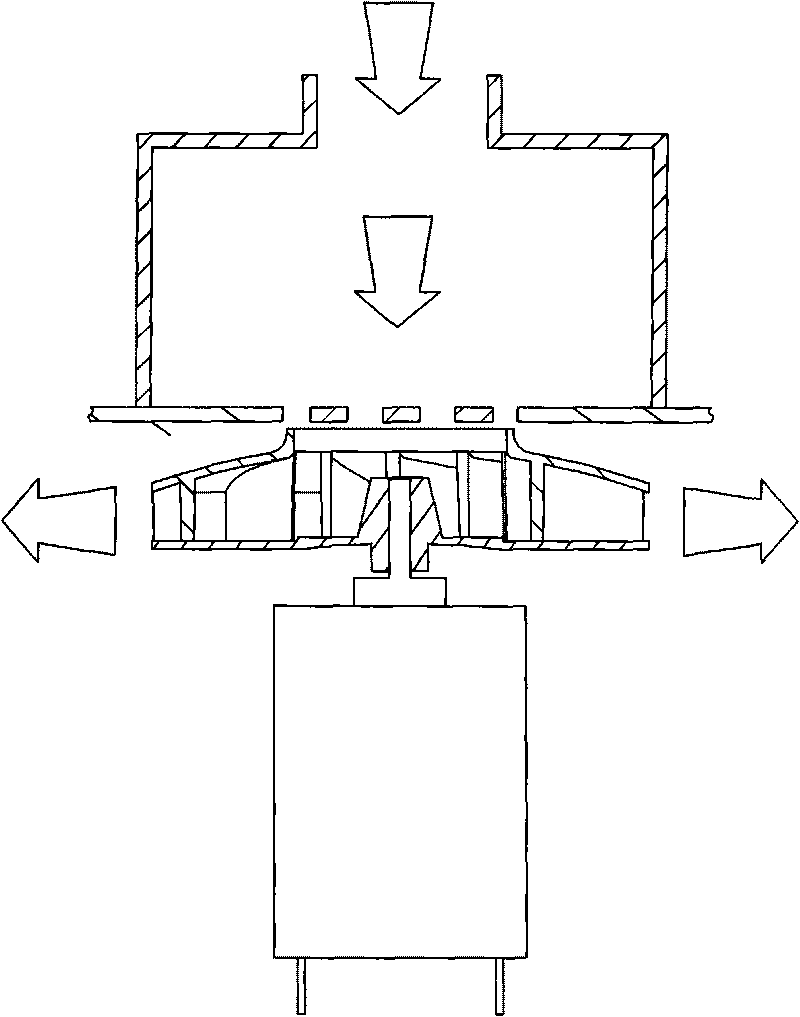

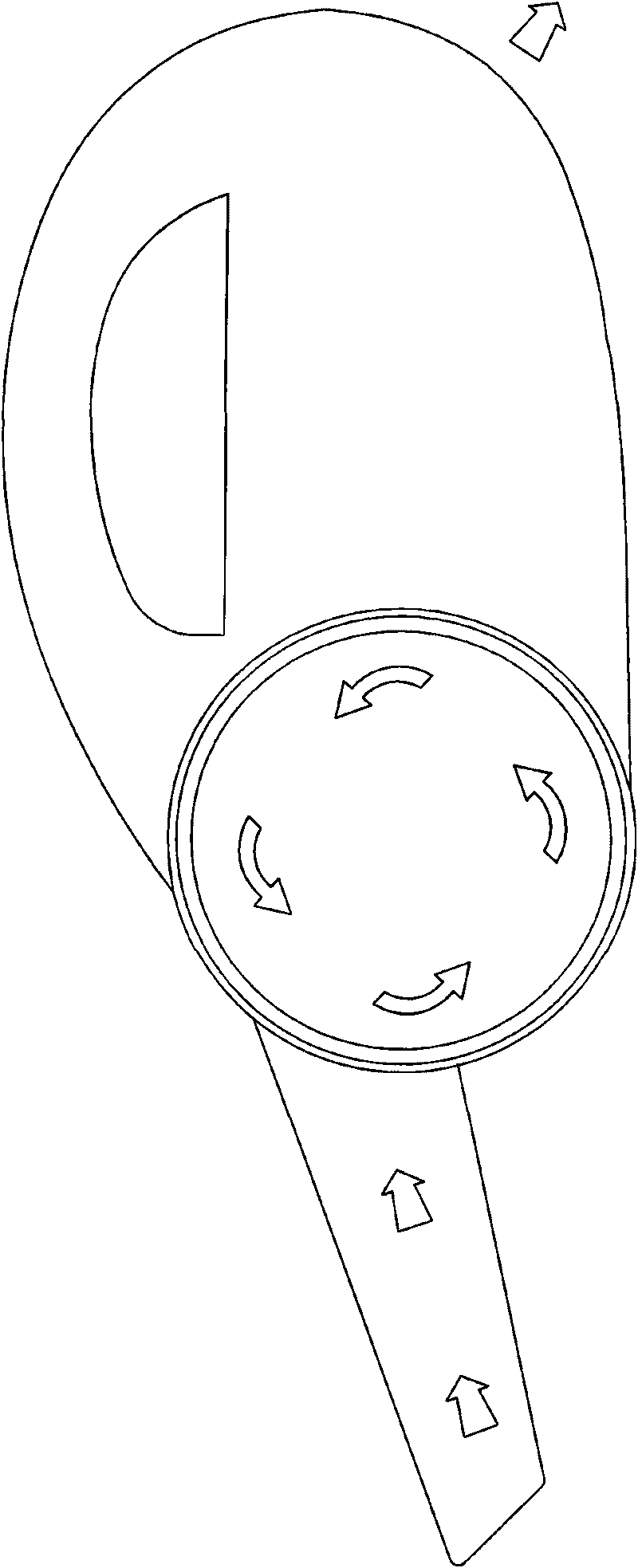

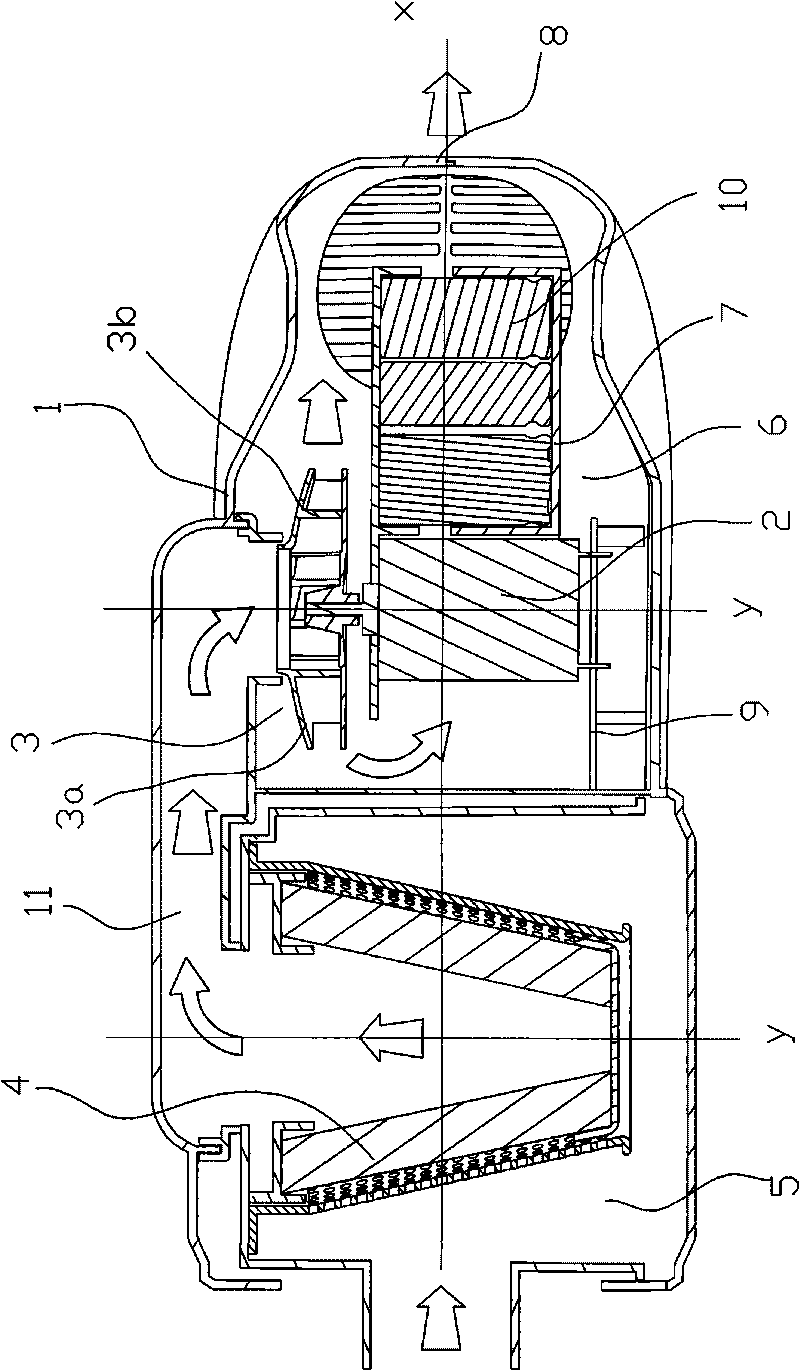

[0017] As shown in the figure, the horizontal direction described herein is the X-axis, and the vertical direction is the Y-axis, whichever is shown in the figure. This kind of vacuum cleaner includes main components such as a housing 1, a motor 2, fan blades 3, and a filter 4. The front of the housing 1 is a dust collection and separation chamber 5, the rear of the housing is a cavity 6, and the rear of the housing 1 The motor 2 is set in the internal cavity 6 through the motor frame 7, and the output shaft of the motor 2 is equipped with the fan blade 3 that discharges the air flow. The key point of the invention is that the fan blade 3 and the motor 2 are arranged in the longitudinal direction in the cavity. , and the fan blade 3 is at least provided with an oblique blade surface 3a that presses the cavity inlet airflow to the motor itself,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com