Device and method for measuring cornea curvature

A technology of cornea and curvature, which is applied in the field of measuring corneal curvature, can solve the problems of increased product cost, longer measurement time, increased measurement calculation error and mechanical failure, and achieves the effect of saving manufacturing cost and maintenance cost, and the method and device are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A more complete understanding of the present invention and its attendant advantages will be obtained by reference to the following detailed description taken in conjunction with the accompanying drawings.

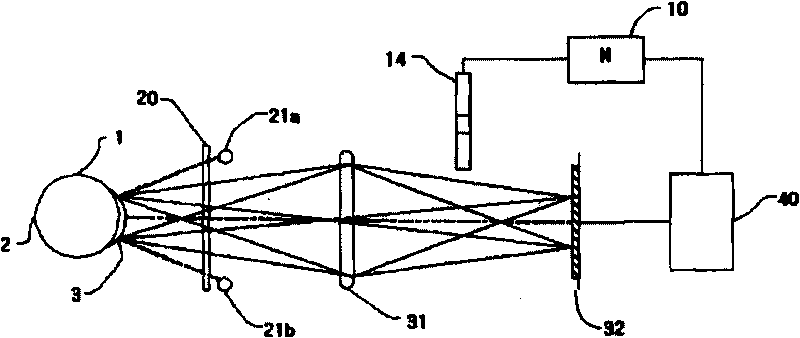

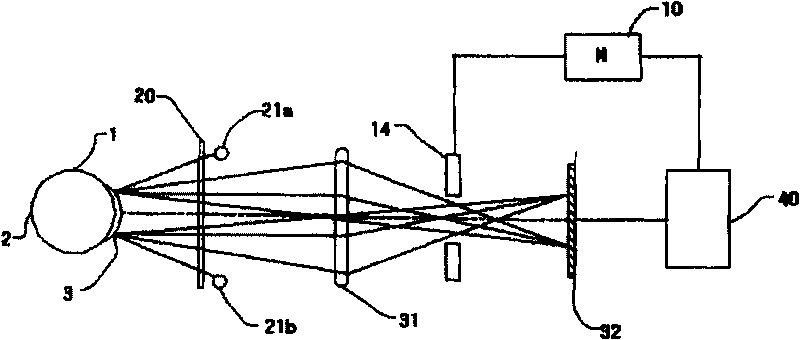

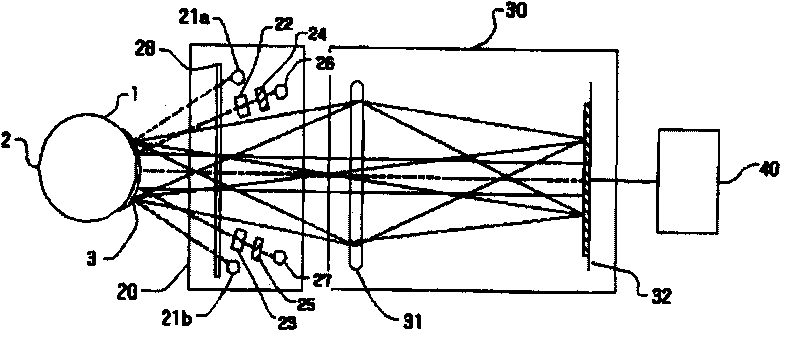

[0026] image 3 is a diagram illustrating a corneal curvature measuring device according to an embodiment of the present invention. Figure 4 is a diagram illustrating a situation where micro-inverted ring light and focused light are incident on the cornea in a keratometry device according to an embodiment of the present invention.

[0027] Such as image 3 Said, according to one embodiment of the present invention, the corneal curvature measuring device includes a micro-inverted ring optical system 20, an imaging optical system 30, and a computing and control unit 40, and also includes a light transmission device for reflecting the measured eye 1 back The measurement light is transmitted to the mirror and relay lens of the imaging optical system 30.

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com