Isothermal forging method for titanium alloy blade

A technology of isothermal forging and titanium alloy, which is applied in the field of warm forging, can solve the problems that the structure performance cannot meet the higher technical requirements, the mold has no better fixing method, and the temperature difference is large, so as to reduce the machining steps and improve the mechanical properties. The effect of improving and improving the precision of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Apply a lubricant on the surface of the pre-forged titanium alloy blade blank, and the thickness of the lubricant is 0.3mm; preheat the high-temperature rotary hearth furnace to 950±10°C, and then place the blade blank in the high-temperature rotary hearth furnace. The blade blank is heated to 950±10°C.

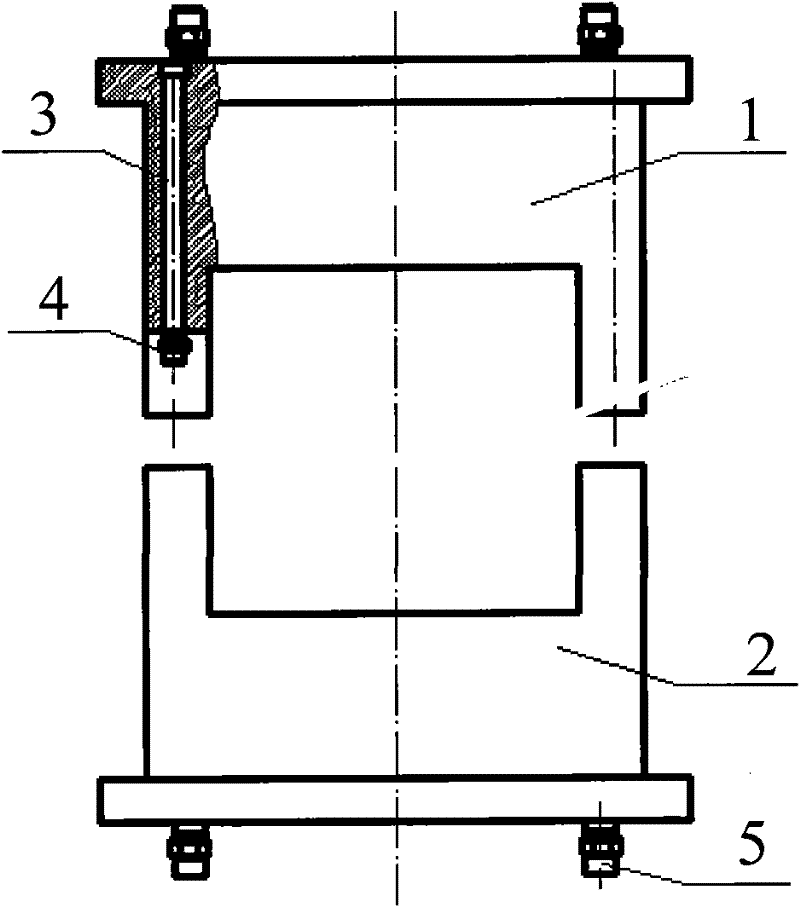

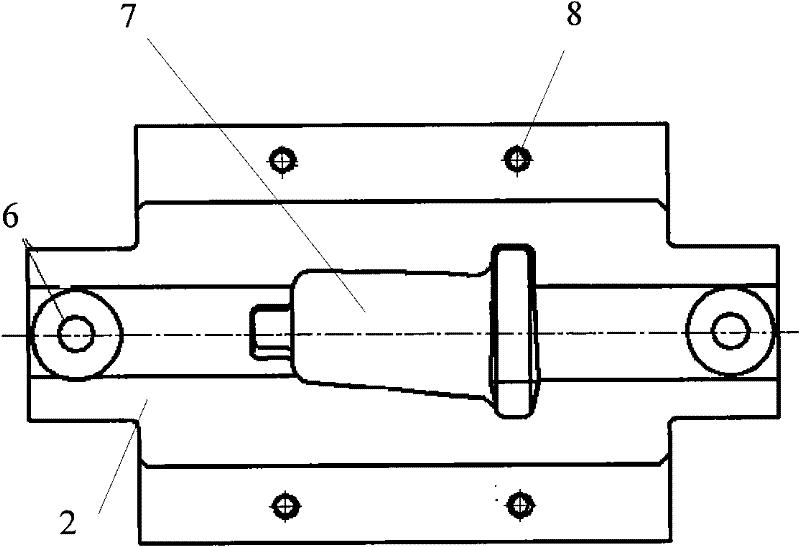

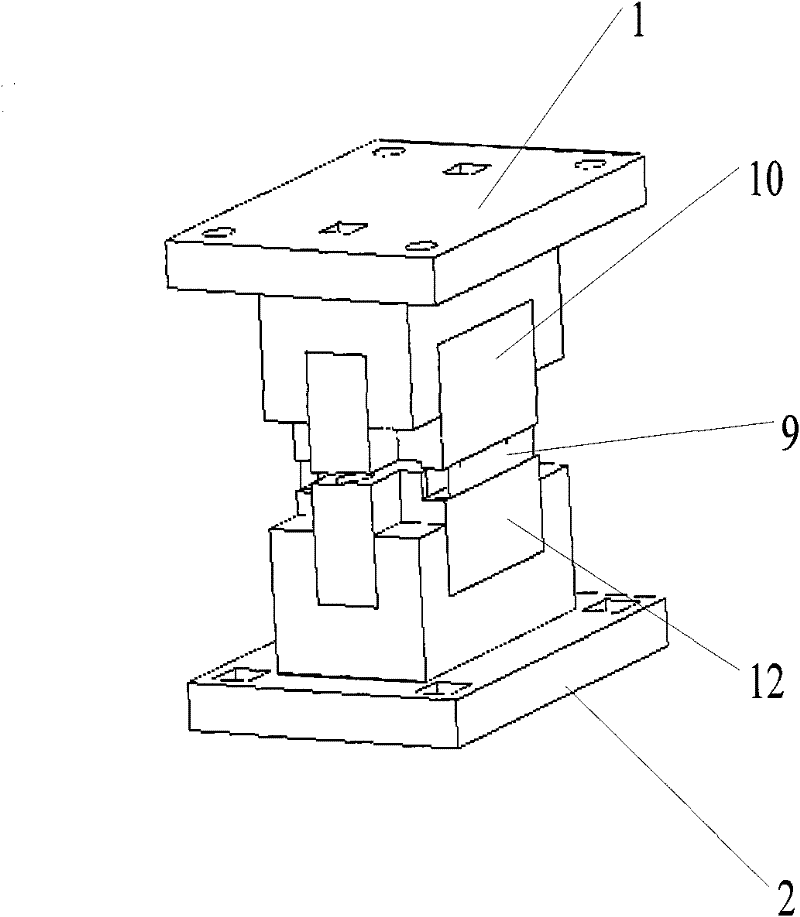

[0031] Fix the two bearing pads on both sides of the lower mold base with bolts respectively, fix the lower mold base in the isothermal forming heater with bolts, fix the upper and lower molds on the upper and lower mold bases with bolts respectively, and the mold and mold base The matching clearance of the surface is ≤0.5mm.

[0032] Fix the isothermal forming heater on the hydraulic press, energize and heat the isothermal forming heater, raise the temperature of the upper and lower molds and upper and lower mold bases to 930°C, and keep them warm for 5 hours.

[0033] Take the blade blank from the high-temperature rotary hearth furnace and put it into the upper and ...

Embodiment 2

[0036] Apply a lubricant on the surface of the pre-forged titanium alloy blade blank, and the thickness of the lubricant is 0.4mm; preheat the high-temperature rotary hearth furnace to 950±10°C, and then place the blade blank in the high-temperature rotary hearth furnace. The blade blank is heated to 950±10°C.

[0037] Fix the two bearing pads on both sides of the lower mold base with bolts respectively, fix the lower mold base in the isothermal forming heater with bolts, fix the upper and lower molds on the upper and lower mold bases with bolts respectively, and the mold and mold base The matching clearance of the surface is ≤0.5mm.

[0038] Fix the isothermal forming heater on the hydraulic press, energize and heat the isothermal forming heater, raise the temperature of the upper and lower molds and upper and lower mold bases to 920°C, and keep them warm for 4 hours.

[0039] Take the blade blank from the high-temperature rotary hearth furnace and put it into the upper and ...

Embodiment 3

[0042] Apply a lubricant on the surface of the pre-forged titanium alloy blade blank, and the thickness of the lubricant is 0.5mm; preheat the high-temperature rotary hearth furnace to 950±10°C, and then place the blade blank in the high-temperature rotary hearth furnace. The blade blank is heated to 950±10°C.

[0043] Fix the two bearing pads on both sides of the lower mold base with bolts respectively, fix the lower mold base in the isothermal forming heater with bolts, fix the upper and lower molds on the upper and lower mold bases with bolts respectively, and the mold and mold base The matching clearance of the surface is ≤0.5mm.

[0044] Fix the isothermal forming heater on the hydraulic press, energize the isothermal forming heater to heat, raise the temperature of the upper and lower molds and the upper and lower mold bases to 900°C, and keep them warm for 3 hours.

[0045] Take the blade blank from the high-temperature rotary hearth furnace and put it into the upper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com