Vacuum clamp for machining porous sheet and using method thereof

A technology of vacuum clamping and thin plate, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing equipment, etc., can solve the problems of difficult and thin plate workpiece machining accuracy, inability to achieve positioning, etc., and achieves high machining accuracy, good implementation effect and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

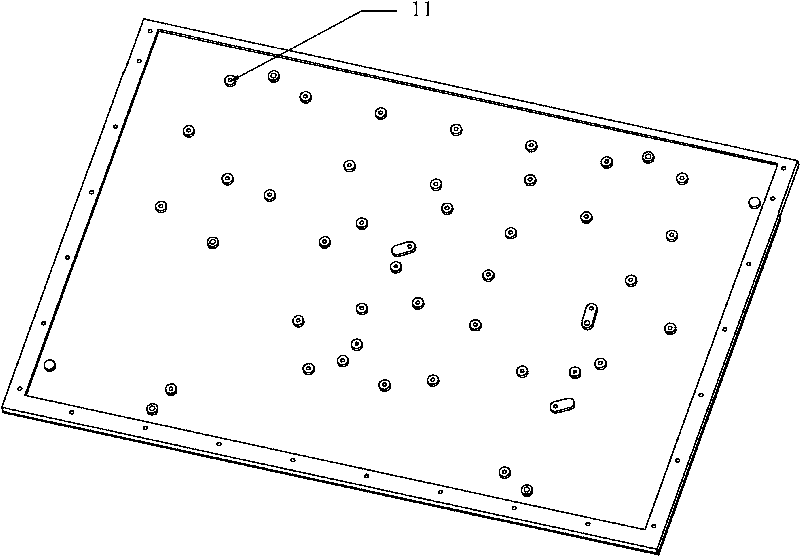

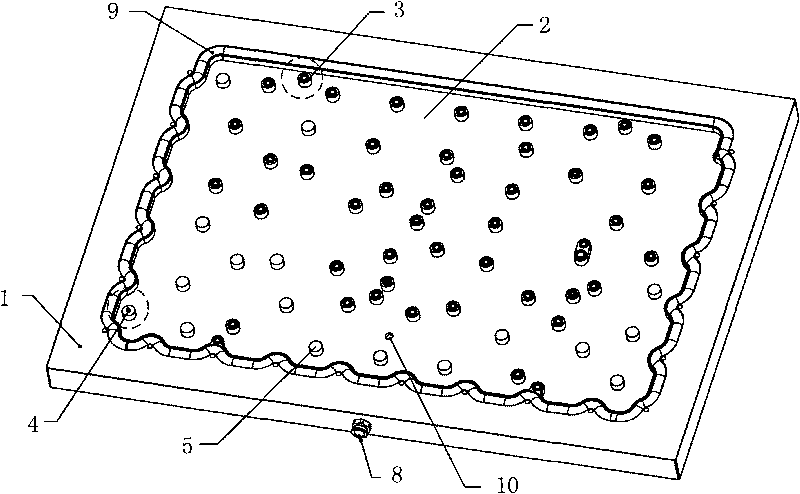

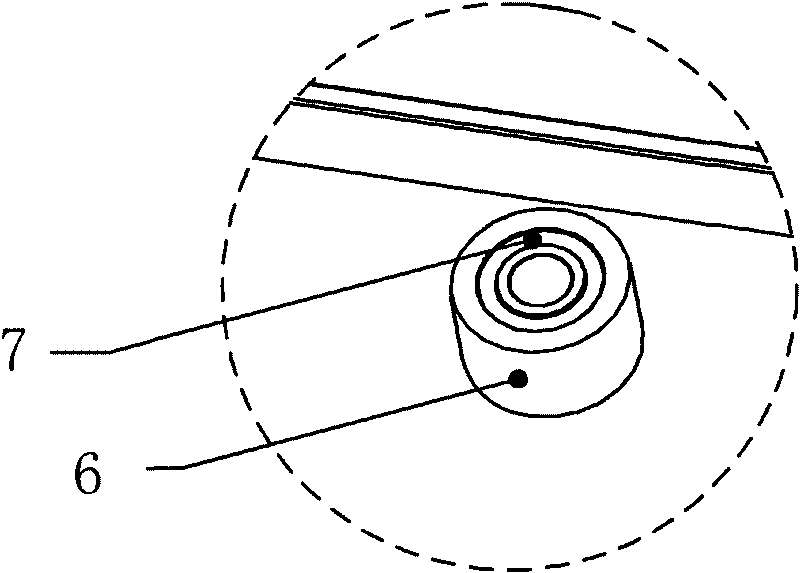

[0028] Such as Figure 1~5 The shown vacuum fixture for porous thin plate processing involves parts to be processed, including a substrate 1, a positioning device, an air guiding device, a vacuum generating device and a sealing device, and its special feature is that: the substrate 1 is distributed with A shallow cavity 2 adapted to the shape of the workpiece to be processed, and air guide holes 10 are distributed in the shallow cavity 2 . Thus, during the processing, the shallow cavity 2 can form a vacuum cavity with the bottom surface of the processed part, and the processed part can be adsorbed on the substrate 1 . At the same time, the positioning device restricts the movement of the processed part on the base plate 1, so that the processed part is in a reliable clamping state for machining. The air guiding device connects the substrate 1 and the vacuum generating device. The sealing device includes a sealing strip 9 and a through-hole sealing element 3. The sealing strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com