Method for manufacturing bodiless lacquer sculptures

A production method and sculpture technology, applied in decorative arts, decorative structures, etc., can solve the problems of unable to fully restore the sculpture effect, single surface effect, unable to meet the various effects of sculpture creation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

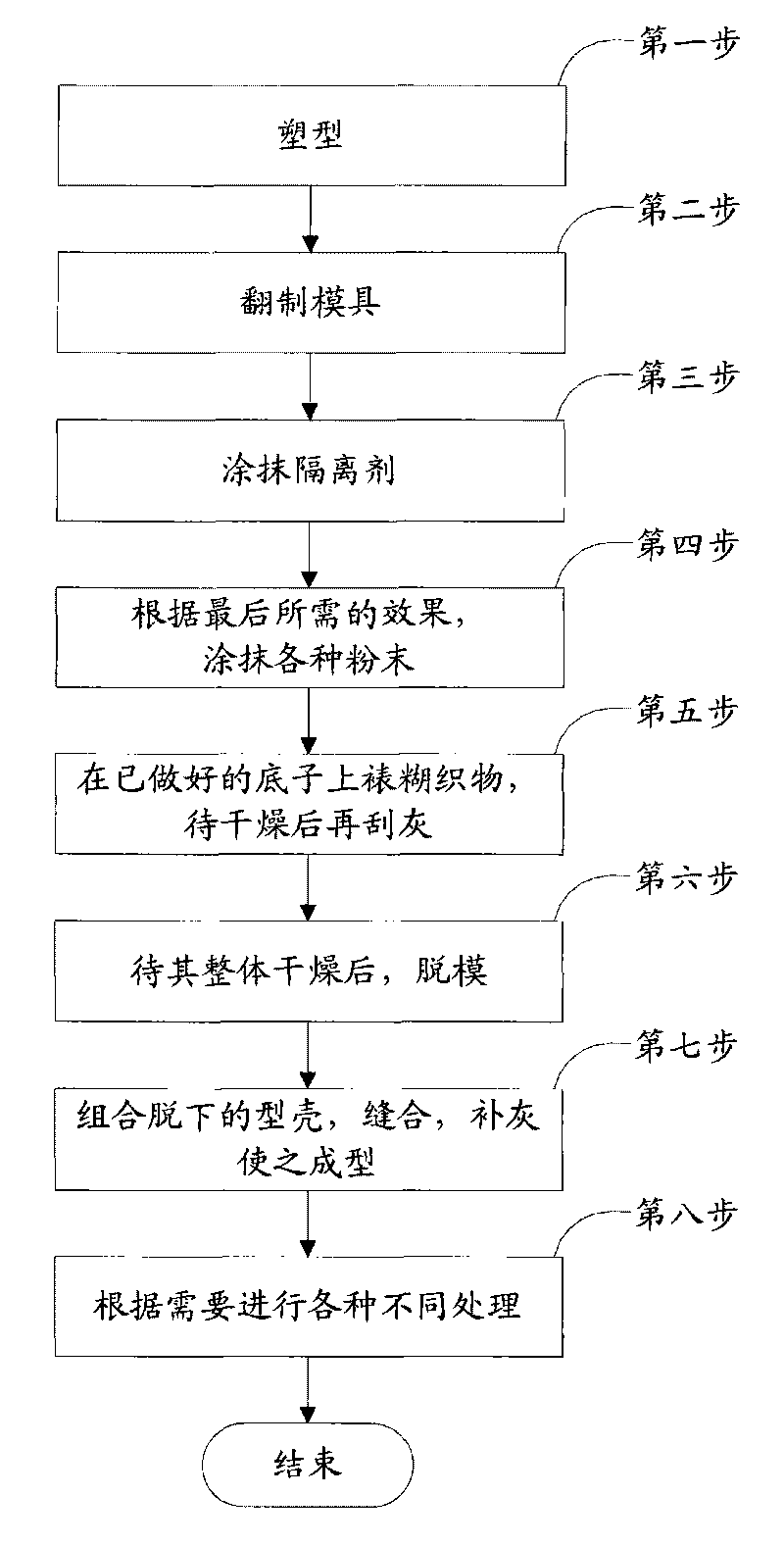

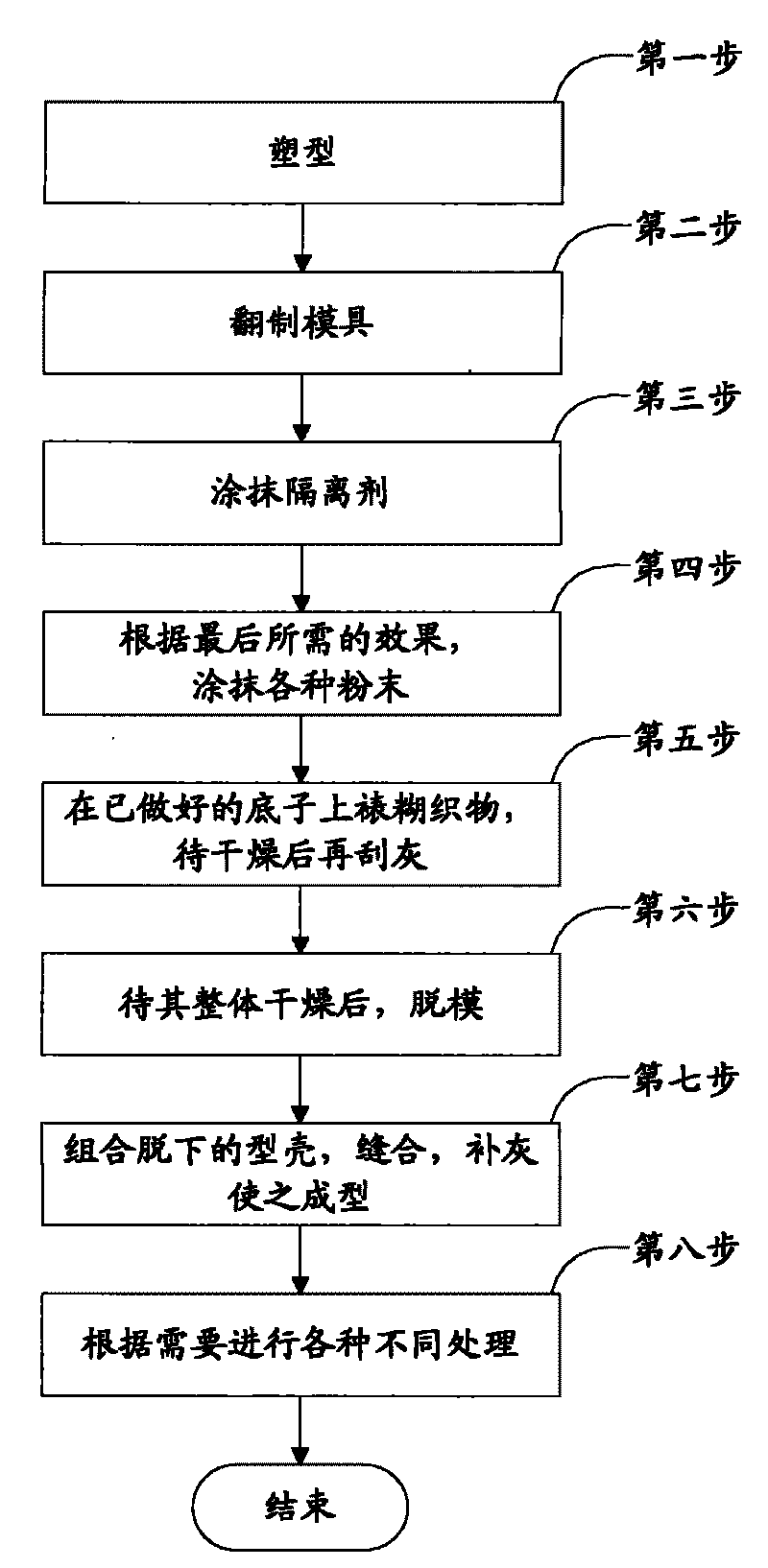

[0021] In order to accurately restore the surface texture effect of sculptural art works by the process of bodiless lacquer, the present invention provides a production method of bodiless lacquer sculpture works, see figure 1 shown, including the following main steps:

[0022] Step 1: Shape with 'sculpting clay'.

[0023] Step 2: Remake the mold.

[0024] Step 3: Apply the release agent.

[0025] Step 4: Apply various powders according to the final desired effect. For example, if you need a copper effect at the end, add copper powder, etc.; if you need a stone effect, add white powder and cyan powder.

[0026] Step 5: Paste the fabric on the finished base, scrape the dust after drying, and paste the fabric. Repeat this process 3-4 times.

[0027] Step 6: After the whole is dry, trim the shell and demould.

[0028] Step 7: Assemble the removed shell, sew it, fill the ash, and make it shape.

[0029] Step 8: Carry out various treatments according to the needs, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com