Method for manufacturing micromodule

A manufacturing method and technology for micro-components, which are applied to manufacturing tools, glass pressing, glass manufacturing equipment, etc., can solve problems such as increased manufacturing cost, low degree of freedom, differences between micro-components and expected results, and achieve optimal utilization, Simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

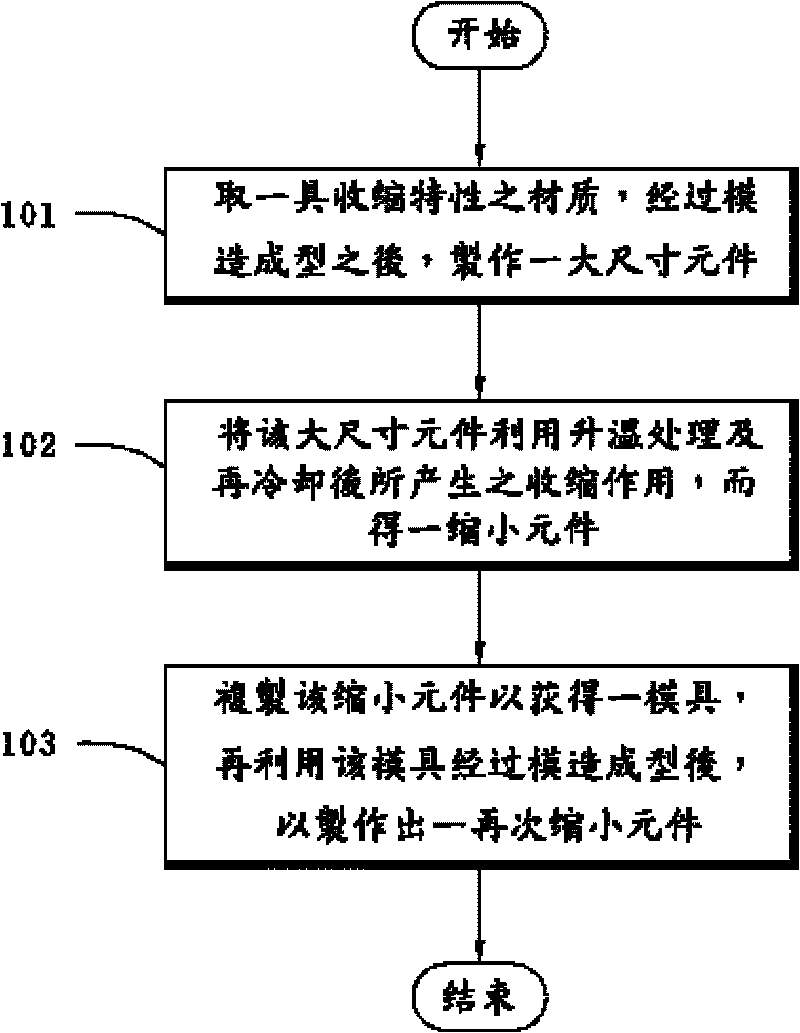

[0018] The present invention is a manufacturing method of micro-components. Since the current technology of micro-components is not easy to grasp the accuracy, and the degree of freedom of the produced micro-components is not high, in order to reduce the difficulty of making micro-components and improve the shape of micro-components degrees of freedom, so the present invention provides the following new micro-component process technology, its processing steps please refer to figure 1 Shown:

[0019] Step 101: firstly, a large-size component is produced by molding with a shrinkable material (such as silicon dioxide), and the shape of the large-size component can be regular or irregular;

[0020] Step 102 heats up the large-sized component, the temperature of the heating process ranges from about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com