Method for manufacturing composite hose

A manufacturing method and composite hose technology, which is applied in the hose field, can solve problems such as internal stress at the bonding point, large difference in pipe diameter, and influence on bonding strength, so as to achieve the effect of reliable bonding and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

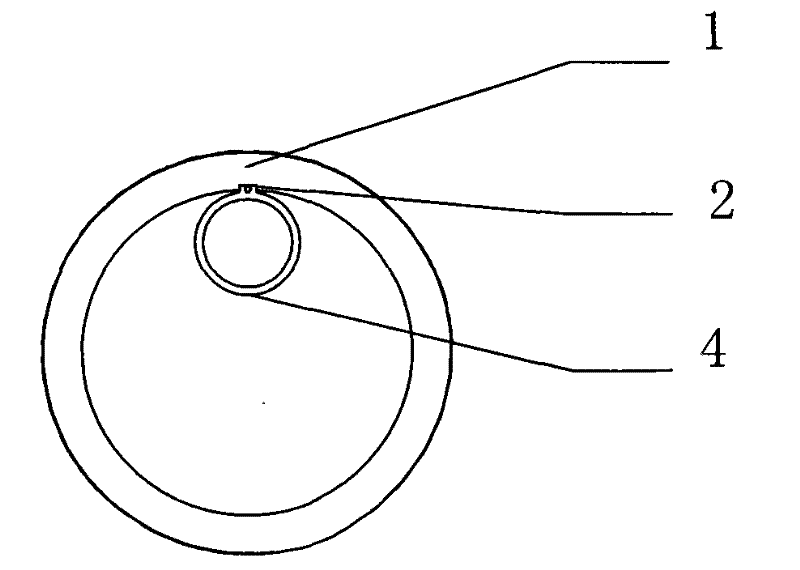

[0021] The composite hose finished product of this embodiment is as figure 1 As shown, the small-diameter tube 4 is adhered to the inner wall of the large-diameter tube 1 by glue 2 .

[0022] The manufacturing process of the composite hose is as follows:

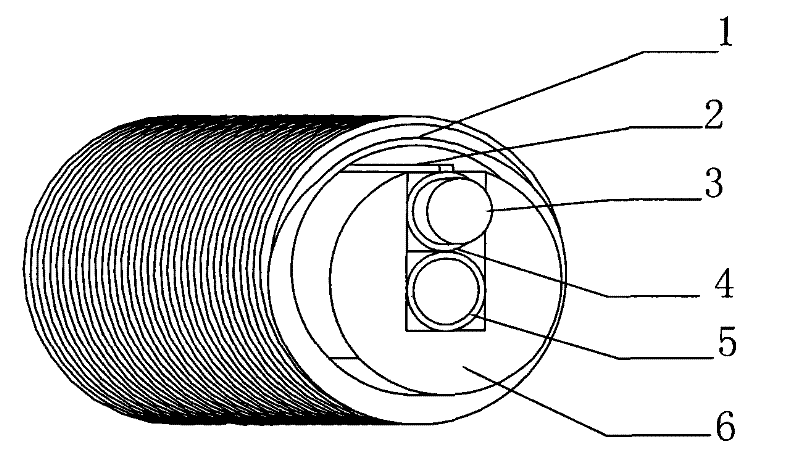

[0023] first step see figure 2 ——Insert the small-diameter tube 4 coated with a strip of viscose 2 (cold glue or hot-melt glue) in the length direction of the outer surface, the silicone inflation hose 5 and the support mandrel 6 with grooves into the large-diameter tube 1 successively; the support core The section of the rod 6 is C-shaped, and the outer diameter matches the inner diameter of the large-diameter pipe 1, so the shape of the large-diameter pipe 1 can be maintained. The inflatable hose 5 is located at the bottom of the groove, the small-diameter tube 3 is located at the upper part of the groove, and the tube is lined with a support mandrel 3, and the outer surface coated with glue 2 is adjacent to the inner s...

Embodiment 2

[0028] The composite hose of this embodiment is manufactured according to special needs, and the finished product structure is also as figure 1 As shown, the manufacturing process is:

[0029] 1) The small-diameter tube 4 is integrated with the special hot-melt adhesive 2 and the heating wire 8 by co-extrusion (see Image 6 );

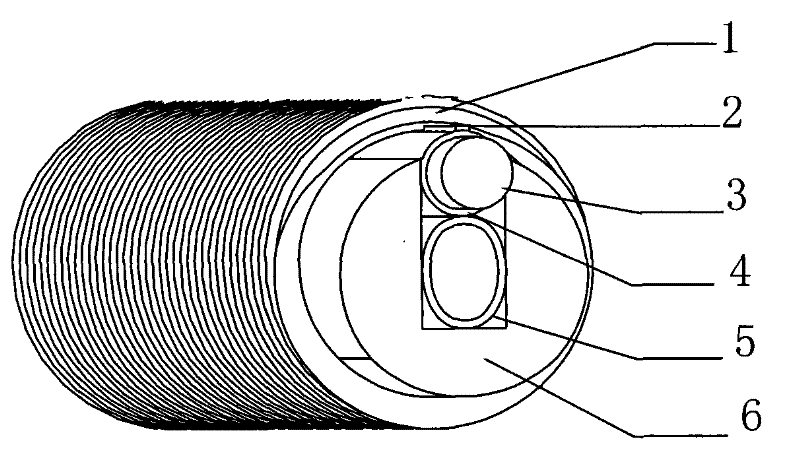

[0030] 2) The large-diameter tube 1 is positioned in the support frame 7 , and the outer surface of the large-diameter tube 1 that is coated with adhesive on the corresponding small-diameter tube 4 abuts against the support frame 7 . The support frame of this embodiment is formed by combining two halves with a semicircular concave cross section (obviously, other structural forms with a "concave" cross section are also possible).

[0031] 3) When the large-diameter pipe 1 is positioned by means of the support frame 7 , the outer surface of the large-diameter pipe corresponding to the small-diameter pipe 4 coated with the outer surface of the glue 2 le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com