Sinking headframe double-layer sheave wheel platform system

A skywheel platform and derrick technology, which is applied in the direction of sinking, drilling equipment, shaft equipment, etc., can solve the problem that it is difficult to arrange lifting equipment on the single-layer skywheel platform of the derrick, achieve overall stability and force, and reduce the height of the center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

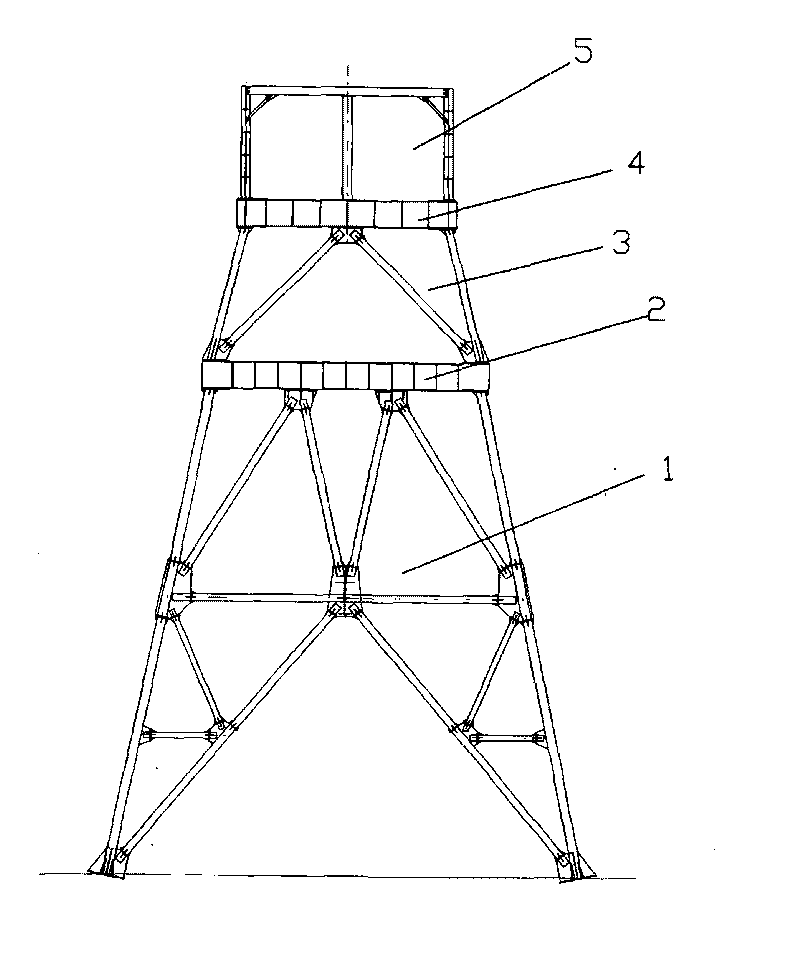

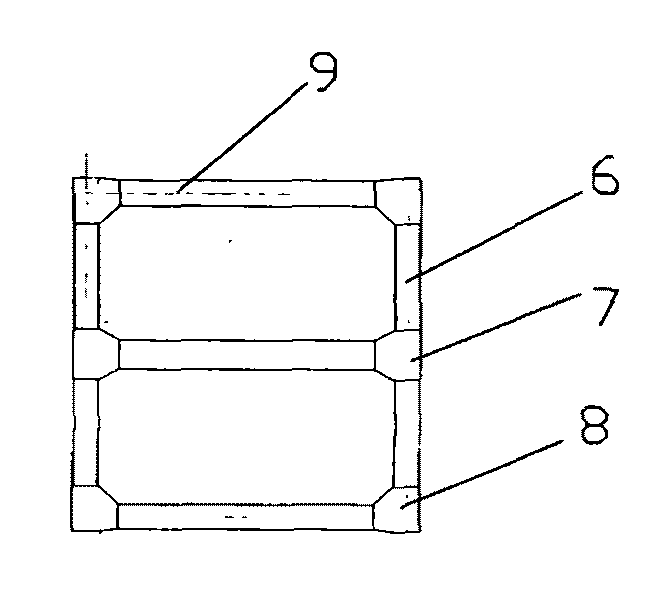

[0016] figure 1 The middle is the front view of the double-layer sky wheel platform of the derrick, which consists of the derrick body I 1, the mesh-shaped sky wheel platform 2, the derrick body II 3, the Japanese-shaped sky wheel platform 4, the sky wheel house 5, the short support I 6, the middle node 7, Corner node 8, long support 9, short support II 10, and short support III11 are composed, and the upper part of the derrick body I 1 is connected to the mesh-shaped sky wheel platform 2, the derrick body II 3, the sun-shaped sky wheel platform 4, and the sky wheel house 5 in sequence. The double-layer skywheel platform system of the sinking derrick is composed of a Japanese-shaped skywheel platform 4 and a mesh-shaped skywheel platform 2 to form a double-layer skywheel platform system.

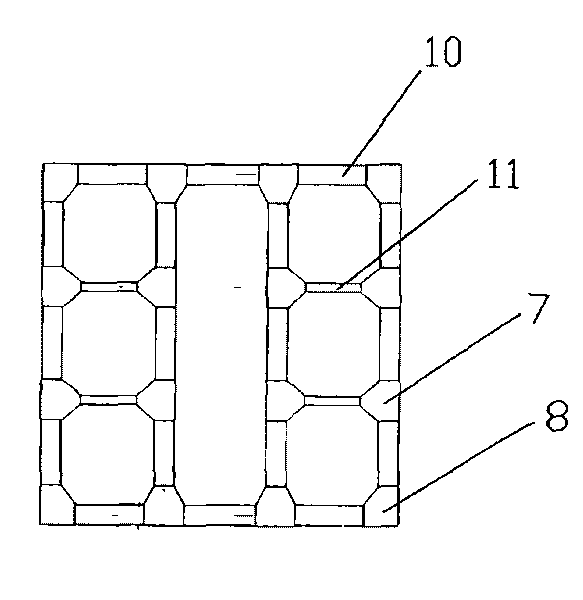

[0017] figure 2 Middle: The mesh-shaped skywheel platform 2 is composed of short support II 10, corner node 8, middle node 7, and short support III11, and its short support II 10 is sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com