Method for controlling well depth positioning in deposit drilling

A control method and a technology for positioning wells, which are applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

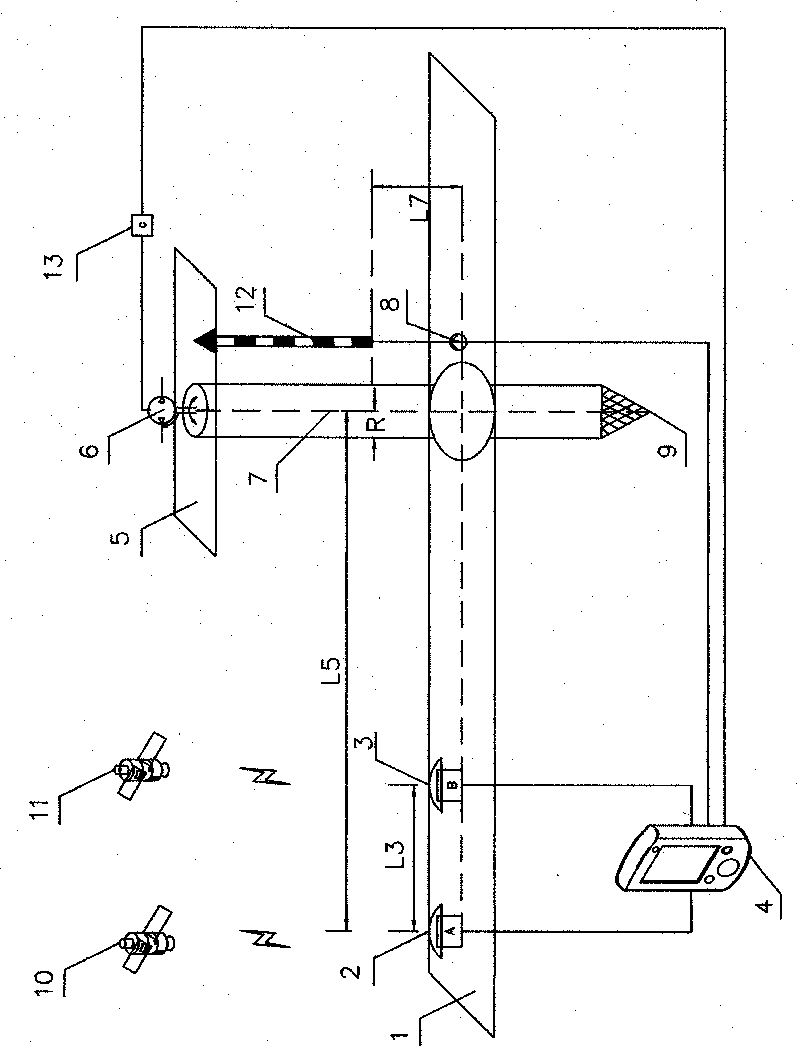

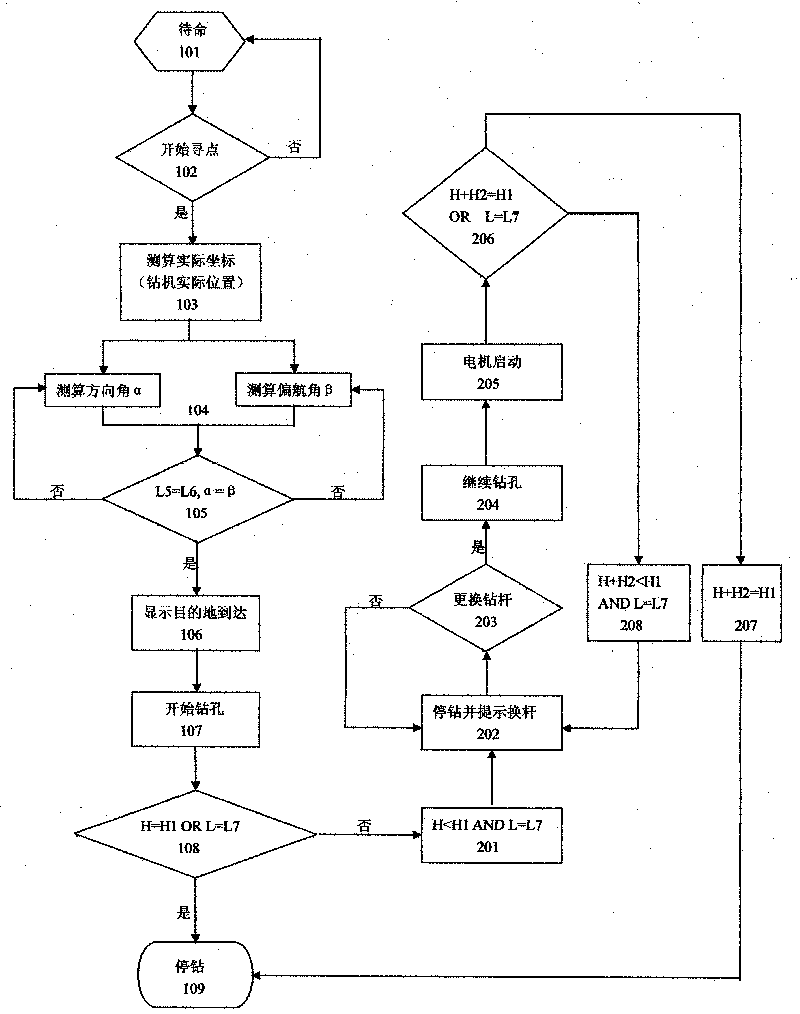

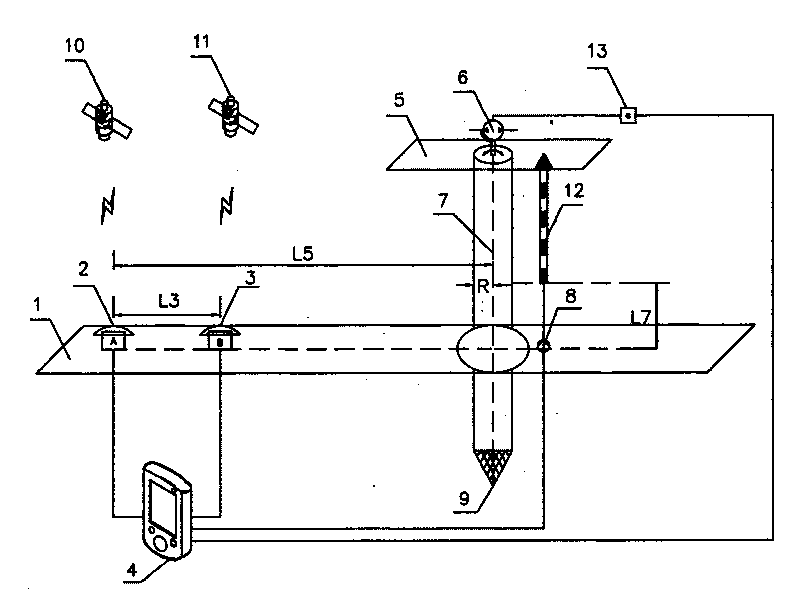

[0015] Step 101 is a standby program. When the measuring device is started, it enters the step 102 of starting to find a point. The positions of the two GPS antennas 2 and 3 are respectively A point and B point, the distance from A point to B point and the distance from A point to the drill pipe. The distance of 7 can be measured by laser rangefinder 8, which are constants L3 and L4 respectively, and the radius of the drill rod is R, then the distance from point A to the center of drill rod 7 is constant L5=L4+R. The GPS module measures the current location coordinates (longitude, latitude, elevation) of the drilling rig and stores them in the vehicle-mounted terminal device. The coordinates are WGS84 longitude and latitude coordinates, which are converted into Beijing May 4th coordinates (X1, Y1, Z1) through the parameter conversion of the vehicle-mounted terminal device 4, which is the step 103 of the actual position of the drilling rig. The coordinate map of the drilling po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com