Fuel injection electronic control unit injector of diesel engine

A diesel engine and fuel injection technology, which is applied in engine control, fuel injection control, engine components, etc., can solve problems such as increased leakage, reduced strength and stiffness, and large volume of high-pressure pipelines, so as to reduce harmful emissions and improve fuel injection. Oil characteristics, improving the effect of in-cylinder combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

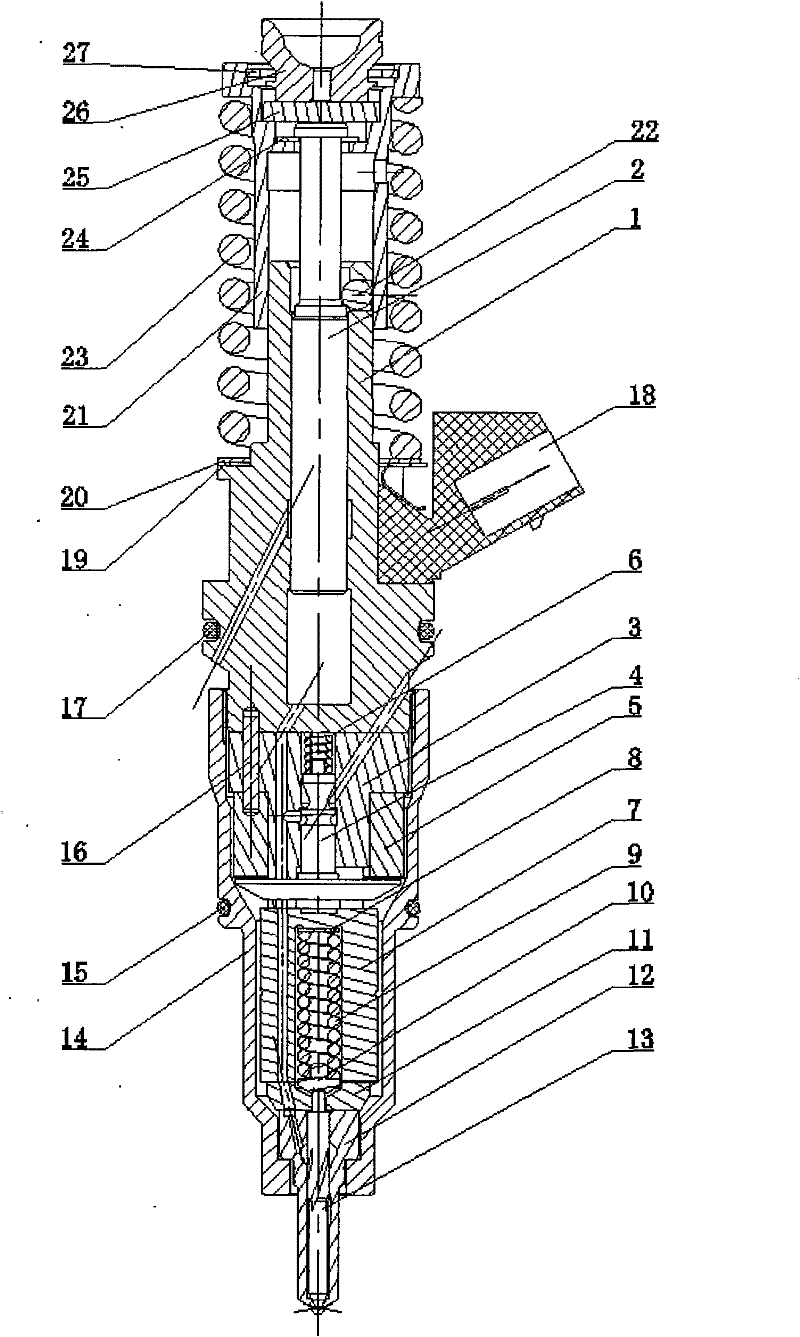

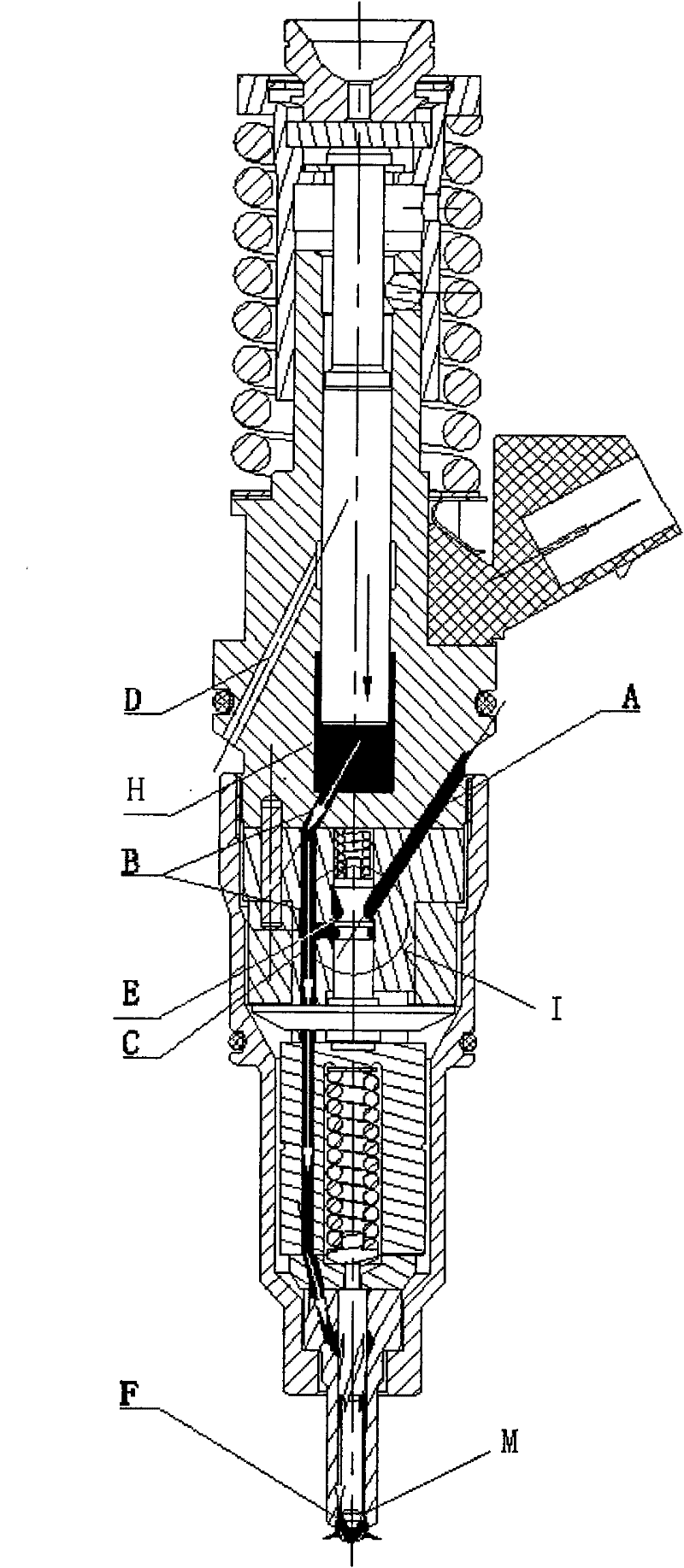

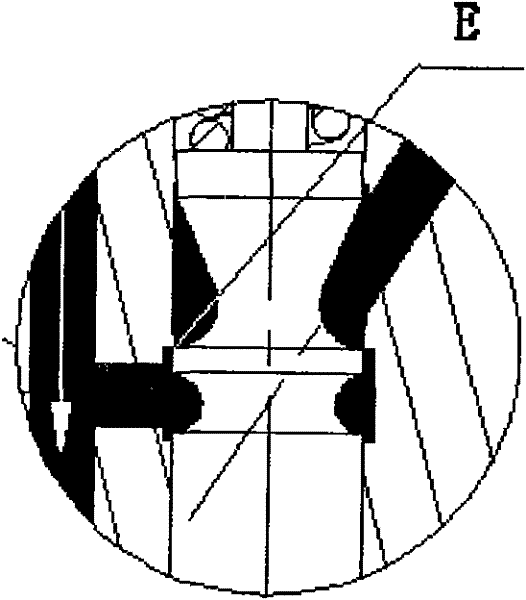

[0022] Such as figure 1 As shown, the diesel engine fuel injection electronically controlled pump nozzle of the present invention includes a plunger coupling, a plunger spring 23, a plunger spring seat 7, a retaining ring 26, a rocker pad 27, a plunger pad 25, an opening stop Ring 24, lock ball 22, fuel injector nut 14, solenoid valve, socket 18 and fuel injector. The fuel injector and the electromagnetic valve are stacked in the fuel injector nut from bottom to top and connected with the plunger couple with threaded pretightening; the plunger spring 23, the circlip 26, the rocker pad 27 and The plunger spacer 25 is fixed on the plunger spring seat 7, and is fixed and limited by the lock ball 22 through the open retaining ring 24 and the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com