Wind power boosting efficient hydroelectric generation method and system

A pressurization system, wind power technology, applied in the direction of hydroelectric power generation, renewable energy power generation, engine components, etc., can solve the problem of not considering the transfer of water kinetic energy, the insufficient and efficient use of water energy, and the lack of pressure water pipes issues such as performance improvement and optimization to achieve the effect of improving utilization efficiency and power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

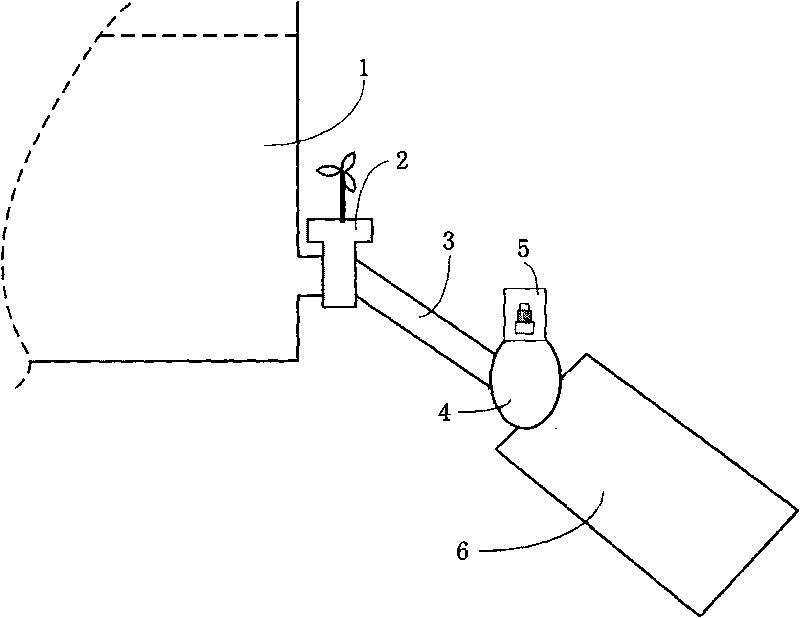

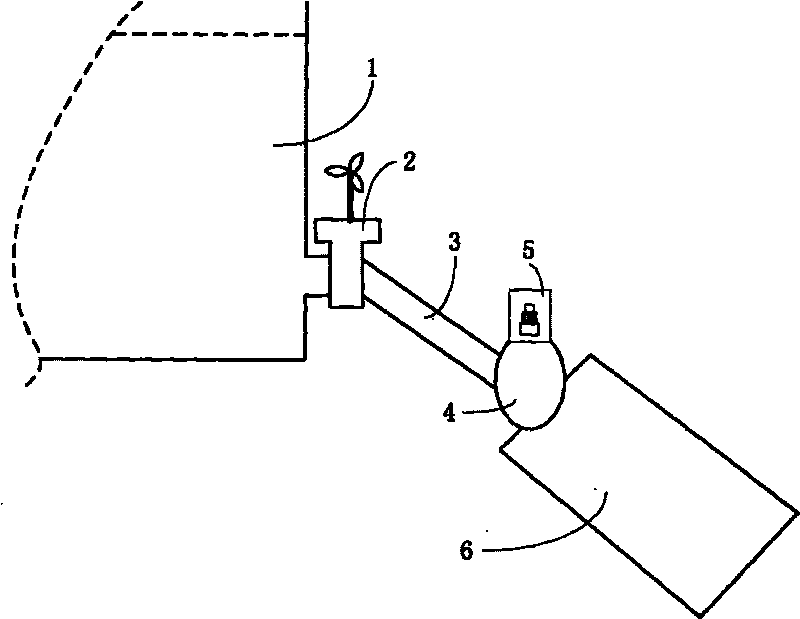

[0059] As shown in the figure, 1 is a reservoir, 2 is an external wind booster, 3 is a pressure diversion pipe, 4 is a water turbine, 5 is a generator, and 6 is a draft tube. The external wind booster 2 is directly connected to the reservoir 1, the water inlet of the pressure water pipe 3 is connected to the external power booster 2, and the water outlet of the pressure water pipe 3 is connected to the water inlet of the water turbine 4. The water outlet of the water turbine 4 is directly connected with the water inlet of the large-diameter draft tube 6 .

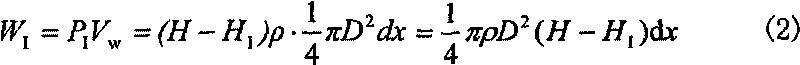

[0060] Taking the pressure diversion pipe 3 with a diameter of 8m as an example, for the water turbine 4, if the water flow velocity of the pressure diversion pipe 3 is 8m / s, without considering the change of the water flow velocity after passing through the water turbine 4 and the influence of other factors, If the diameter of the draft pipe 6 is twice the pipe diameter of the pressure diversion pipe 3, when the draft pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com