Vacuum valve

A technology of vacuum valve and valve core, which is applied in the direction of lifting valve, valve details, valve device, etc., and can solve the problem of complex decomposition operation process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0046]

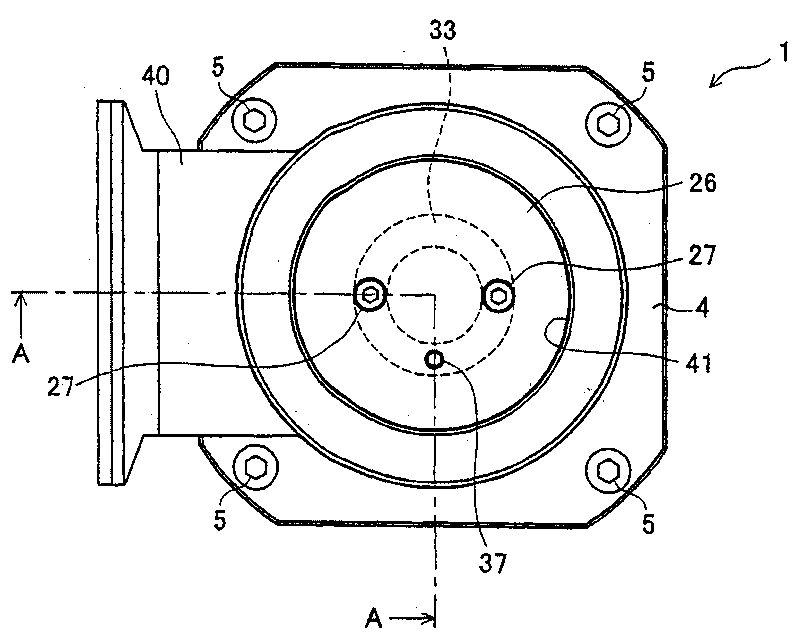

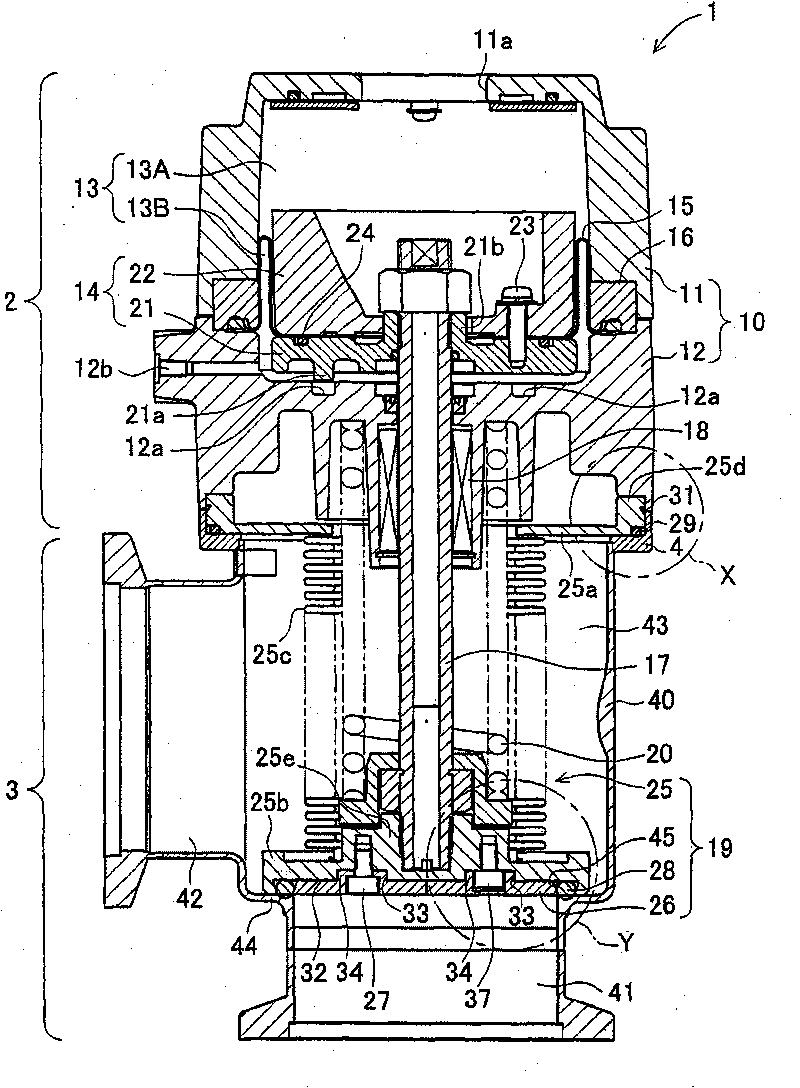

[0047] figure 1 is a bottom view of the vacuum valve 1. figure 2 yes figure 1 The AA profile.

[0048] The vacuum valve 1 has a drive unit 2 and a valve unit 3 . The driving part 2 and the valve part 3 are connected by four bolts 5 to form the appearance of the vacuum valve 1 .

[0049] Such as figure 2 As shown, the valve part 3 is arranged in the valve housing 40 . The first port 41 and the second port 42 of the valve housing 40 communicate via a valve chamber 43 . A valve seat 44 is formed on the inner surface of the valve chamber 43 . The valve body 19 is provided in the valve chamber 43 , and the valve body 19 can abut against the valve seat 44 or be separated from the valve seat 44 . In the valve chamber 43 of the valve housing 40, a bellows 25 as an example of a partition wall is arranged, and the bellows 25 is expandable and contractible according to the movement of the valve body 19. As shown in FIG. The connecting portion 4 is fixed to the outer ...

no. 2 approach

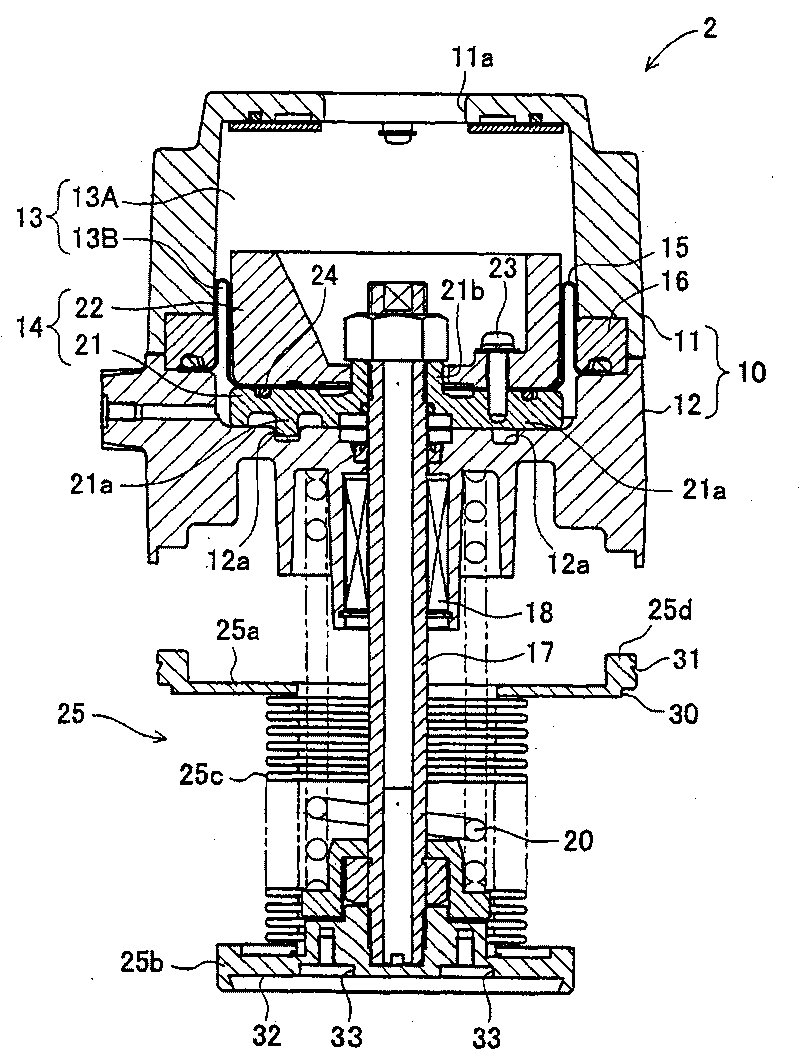

[0083] Next, a second embodiment of the present invention will be described with reference to the drawings. Figure 6 It is a cross-sectional view of a vacuum valve 1A according to a second embodiment of the present invention.

[0084] The vacuum valve 1A of the second embodiment is mainly different from the first embodiment in the connection structure of the drive unit 2 and the valve unit 3 . Therefore, here, the description will focus on points different from those of the first embodiment. In addition, about the same structure as 1st Embodiment, the same code|symbol as 1st Embodiment is attached|subjected in drawing, and description is abbreviate|omitted suitably.

[0085] The cylinder 10 is configured such that a closing member 62 and a cover 63 are attached to a cylindrical cylinder valve housing 61 , and a piston 68 is loaded to form a piston chamber 13B. The cylinder valve housing 61 is formed with an operation port 61a to communicate with the piston chamber 13B. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com