Manufacturing method of LED lamp string

A technology of LED light strings and manufacturing methods, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., and can solve problems that affect product use and life, difficult to achieve sealing, and difficult to control appearance consistency. problem, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

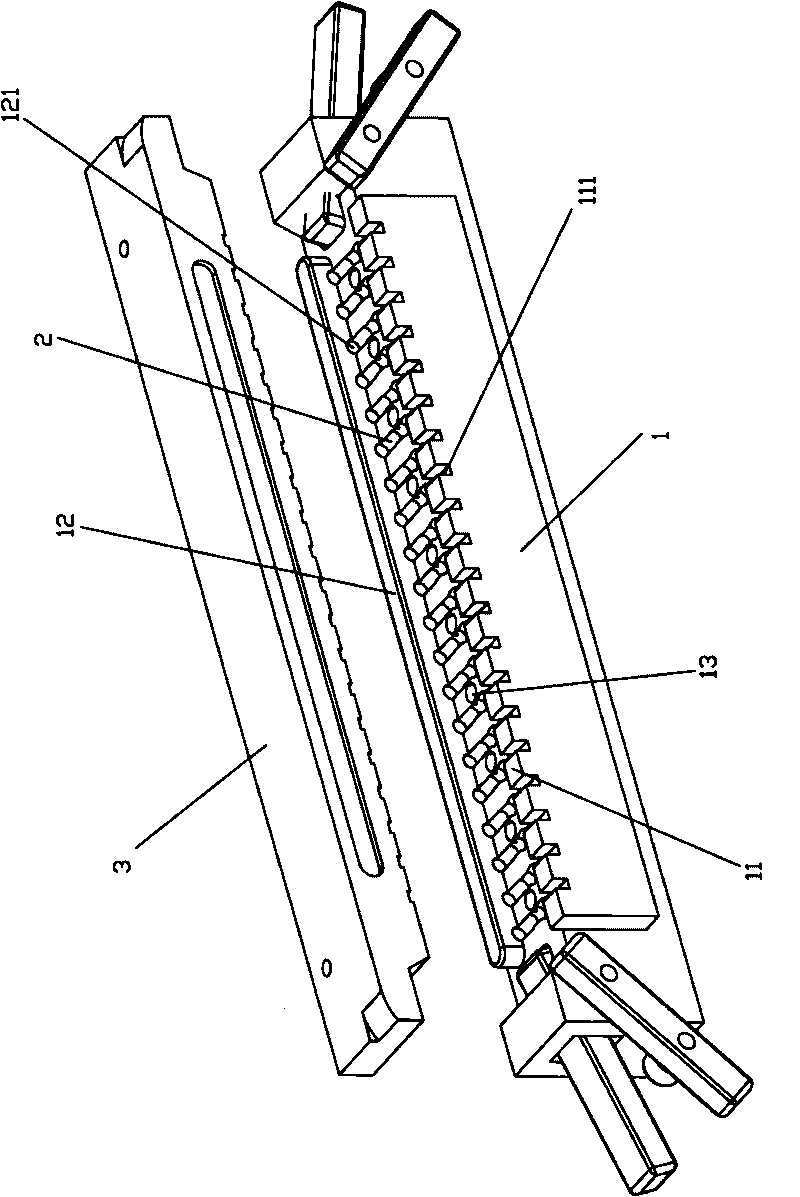

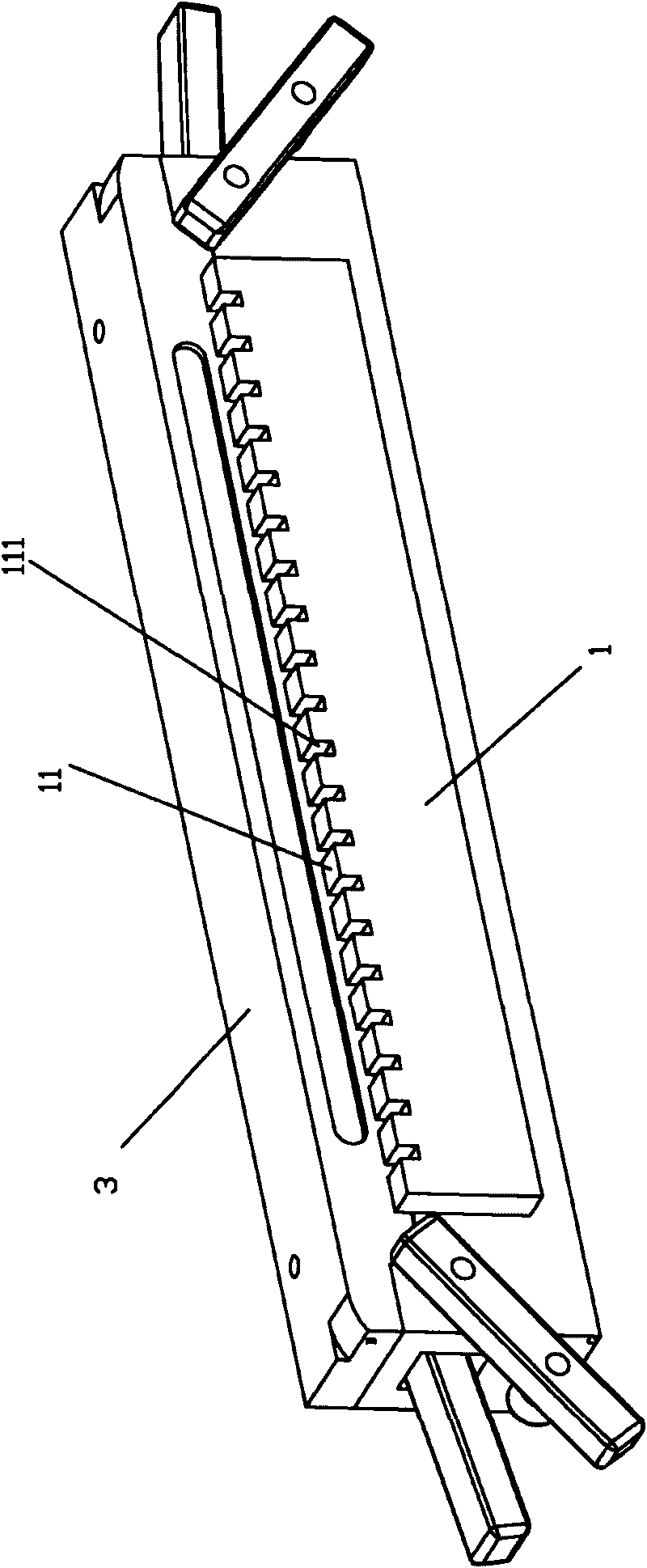

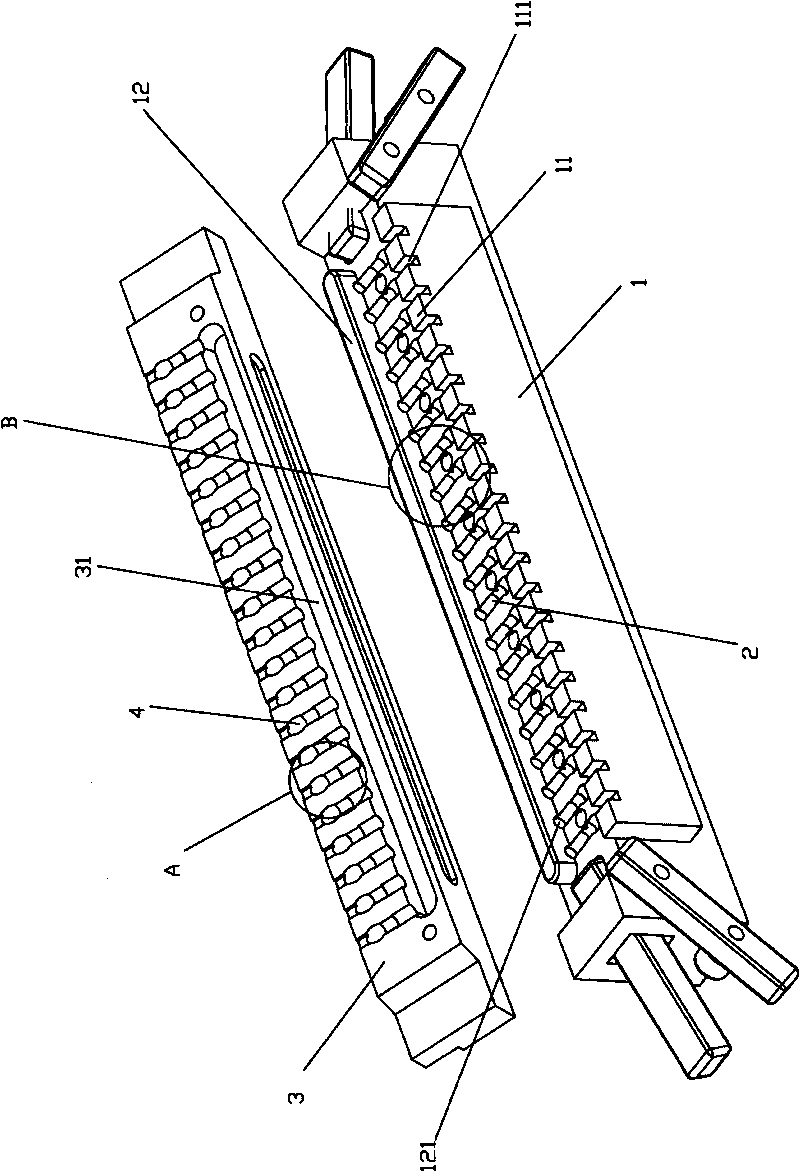

[0020] Referring to the accompanying drawings, a manufacturing method of an LED light string according to the present invention is manufactured by using the following mold, which includes:

[0021] The lower mold 1 has a plurality of lower concave cavities 2 arranged side by side along the length direction along the length direction, and the front end of the lower cavity 2 is provided with a long front boss 11 along the length direction. The long front boss 11 is provided with a plurality of recesses 111 corresponding to the lower cavity 2, and the rear end of the lower cavity 2 is provided with a long rear boss 12 arranged along the length direction. The front side of the boss 12 is provided with a plurality of front holes 121 corresponding to the lower cavity 2, and the lower half of each front hole 121 is respectively connected with the corresponding lower cavity 2;

[0022] An upper mold 3 that can be mold-closed with the lower mold, the bottom end of the upper mold 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com