Light-emitting diode module

A technology of light-emitting diodes and circuit boards, which is applied in the field of light-emitting diode modules, can solve problems such as poor contact between light-emitting diode light strips and flexible circuits, insufficient joint strength to resist, and limited joint area, so as to reduce the risk of poor contact or falling off The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

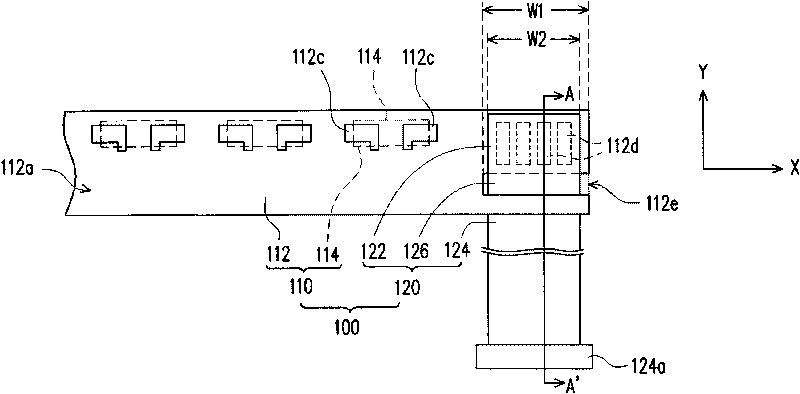

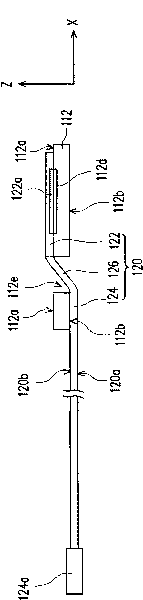

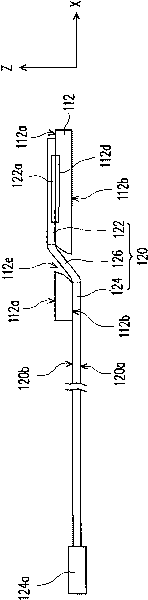

[0039] figure 1 is a schematic top view of a light emitting diode module according to an embodiment of the present invention, and Figure 2A as well as Figure 2B for along figure 1 The cross-sectional schematic diagram of the A-A' section line in the middle. Please refer to figure 1 and Figure 2A , the LED module 100 of this embodiment is suitable for electrical connection with a control circuit board (not shown), and the LED module 100 includes an LED light bar 110 and a flexible circuit 120 . The LED light bar 110 includes a circuit board 112 and a plurality of LED elements 114 . The circuit board 112 has a first surface 112a (or called an upper surface), a second surface 112b (or called a lower surface) opposite to the first surface 112a, a plurality of first contacts 112c, and a plurality of second contacts 112d and a slot 112e, and the first contact 112c and the second contact 112d are located on the first surface 112a. The LED element 114 is disposed on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com