Continuous-rotation heat accumulating type air preheater

An air preheater, regenerative technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve problems affecting the service life of burner refractories, combustion effects and system stability, and achieve The effect of improving the overall combustion effect, improving the sealing condition, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The preferred embodiment of the continuous rotary regenerative air preheater of the present invention is:

[0019] It includes a cylindrical heat storage body. The upper and lower parts of the cylindrical heat storage body are respectively equipped with an upper wind cover and a lower wind cover. The upper wind cover and the lower wind cover are respectively fixed on the frame body. The cylindrical heat storage body is connected with a rotary driving device;

[0020] External seals are respectively provided between the outer circumferences of the upper wind cover and the lower wind cover and the outer circumference of the cylindrical heat storage body;

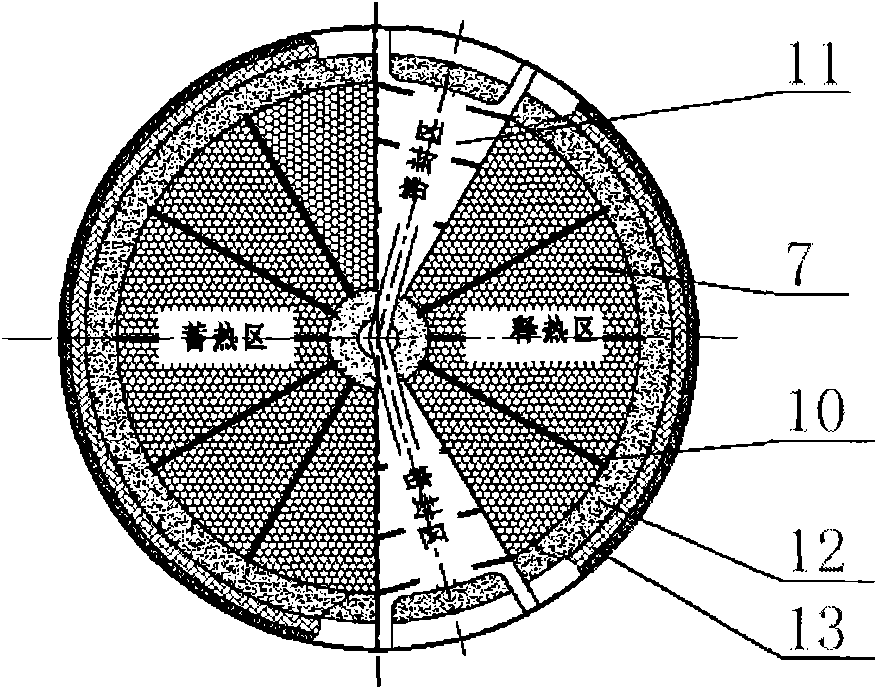

[0021] The upper hood is provided with a high-temperature flue gas inlet and a high-temperature air outlet, and a fire-resistant partition wall is provided between the high-temperature flue gas inlet and high-temperature air outlet, and an upper internal seal is provided between the fire-resistant partition wall and the...

specific Embodiment

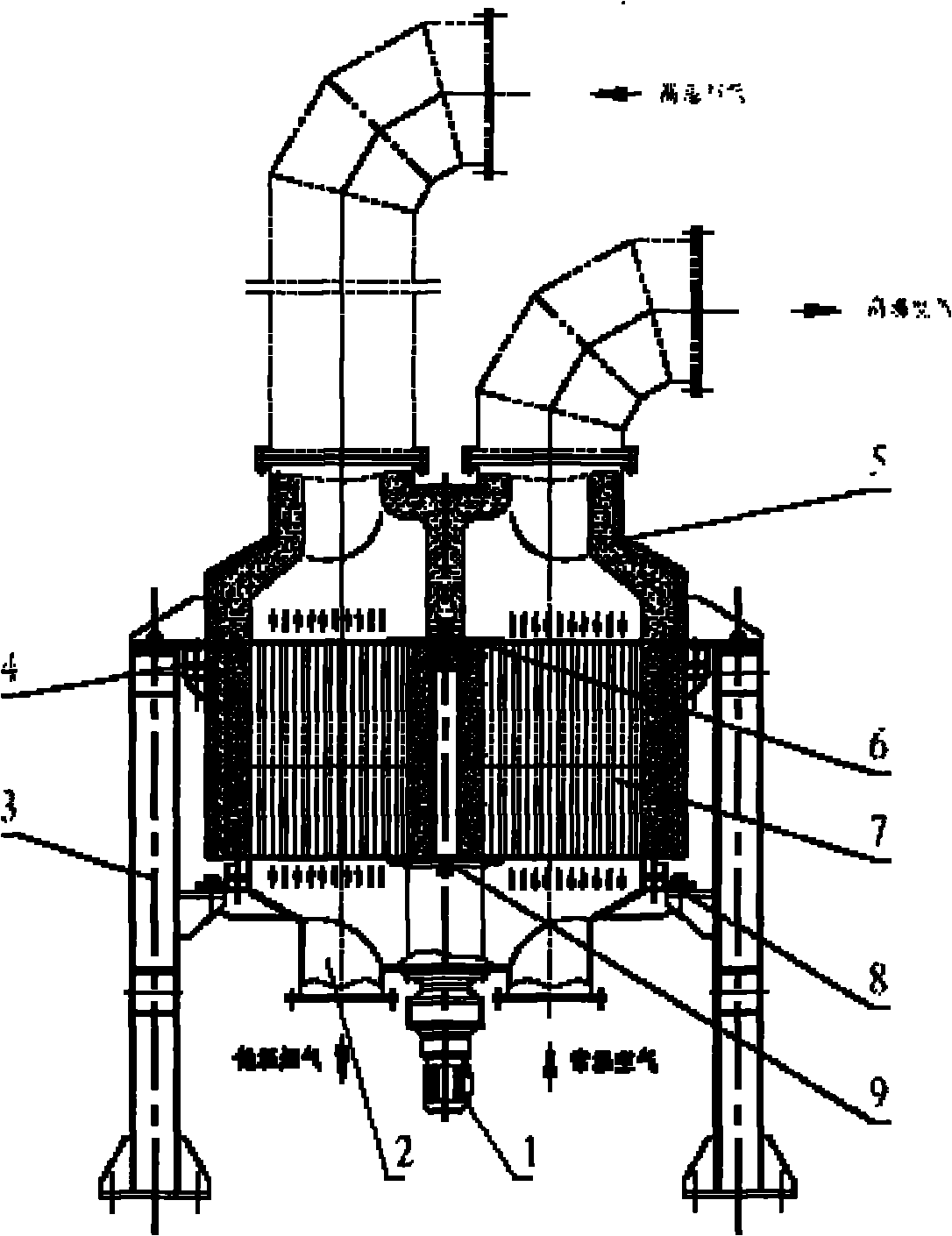

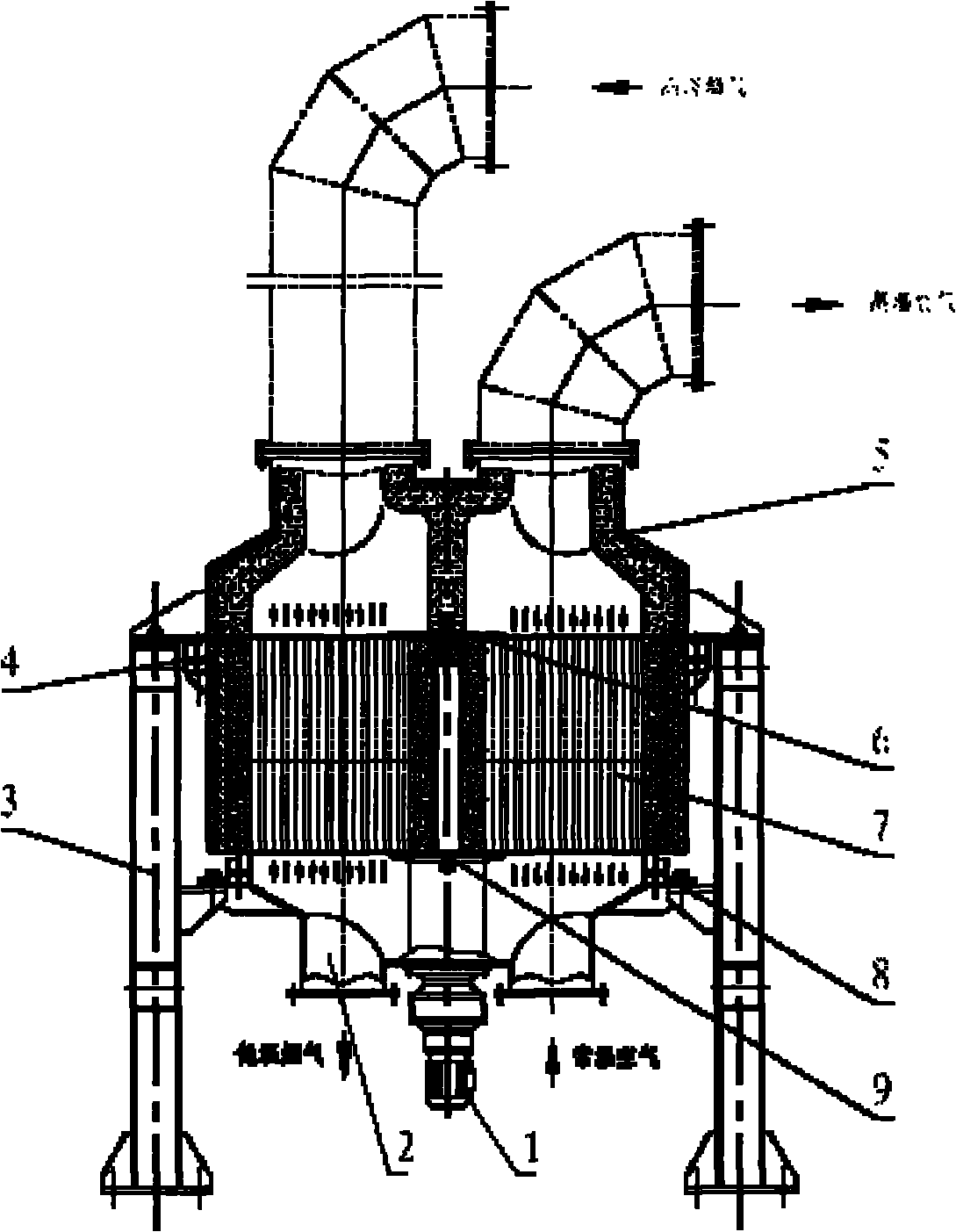

[0034] Such as figure 1 As shown, the equipment includes a driving device 1, a lower wind cover 2, an upper wind cover 5, a frame body 3, an upper water seal 4, a lower water seal 8, an upper inner seal 6, a lower inner seal 9, a heat storage body 7, etc. part.

[0035] The center of the bottom of the regenerator 7 is provided with a shaft extending out to connect with the drive device 1. The regenerator 7 is concentrically installed on the lower wind cover 2, driven by the drive device 1, and rotates at a constant speed between the lower wind cover 2 and the upper wind cover 5. , The lower windshield 2 and the upper windshield 5 are firmly connected with the frame body 3 .

[0036] The upper and lower hoods 2 and 5 are conical cylinder structures, and two pipe holes are symmetrically opened on the conical surface to discharge smoke and air respectively. A steel partition is set between the two pipe holes.

[0037] The outer seals between the upper and lower windshields 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com