A multi-fuel heating furnace

A heating furnace, multi-fuel technology, applied in solid heating fuels, combustion methods, household stoves/stoves, etc., can solve the problems of small-area tent heating, which are not well solved, unable to maintain continuous combustion, and high use costs, Achieve the effect of good high altitude adaptability, strong service support ability, and extended fire sealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

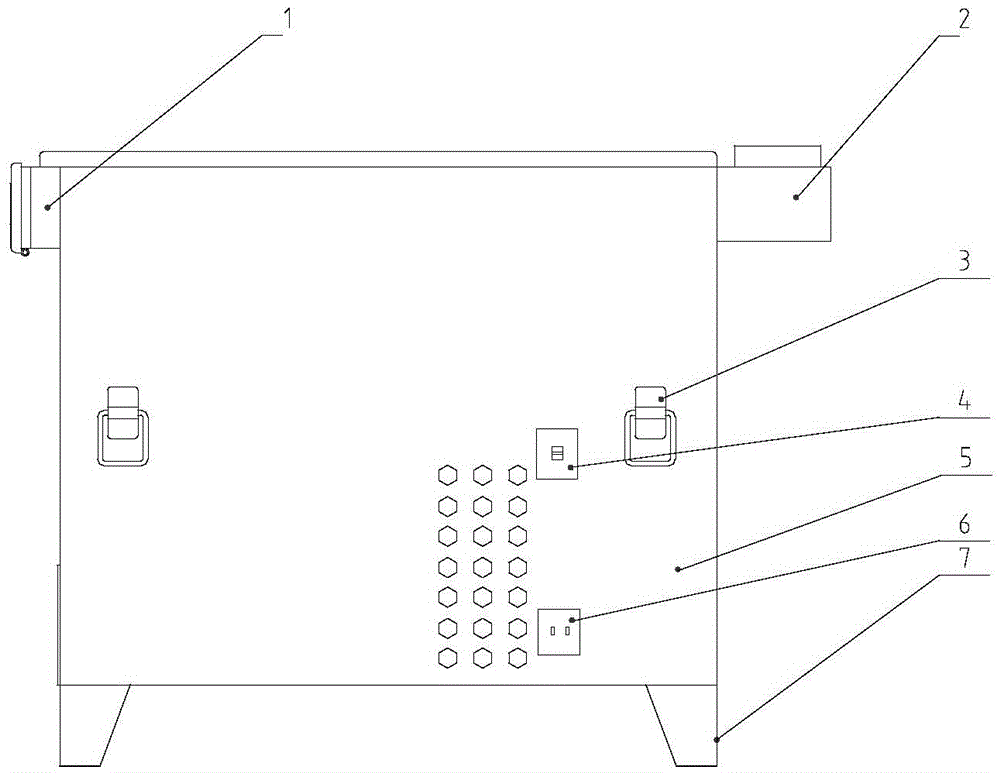

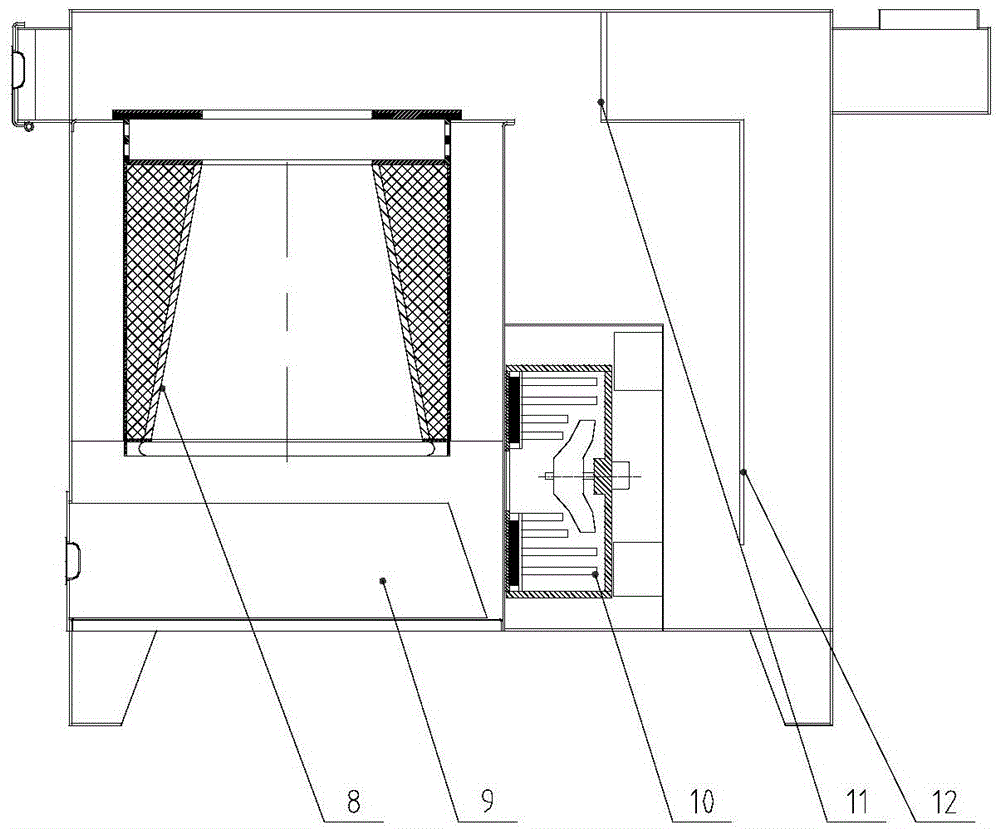

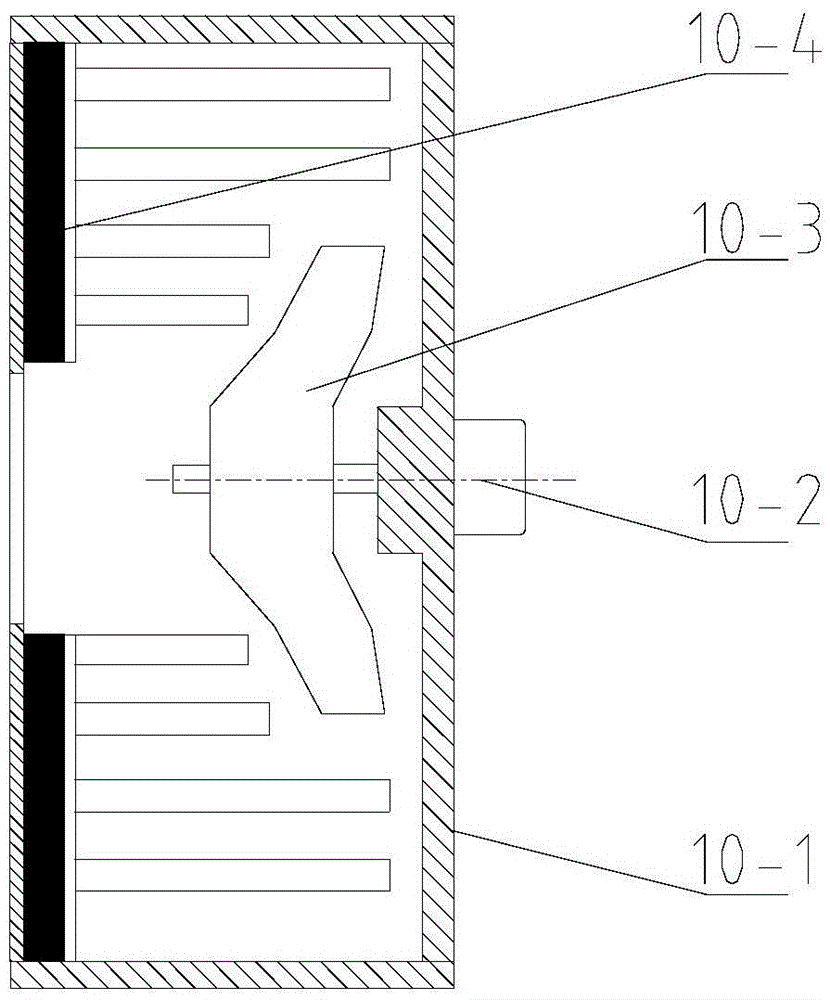

[0021] Such as figure 1 and 2 As shown, the present invention comprises a furnace body 5, and a furnace core assembly 8 is arranged in the furnace hearth of the furnace body. The furnace core assembly 8 is used for burning coal and can be taken out from the furnace body 5, and a relatively The large space is used for burning firewood or dry animal dung, etc., thereby increasing the consumption of firewood and dry animal dung, and improving the heat supply; the burned ash falls into the ash hopper 9 below the furnace, and the ash hopper 9 can be drawn out for The shovel-shaped structure, in addition to collecting ash, can also shovel coal; the lower part of the furnace body 5 and one side of the furnace are provided with a compartment, which communicates with the outside world through a number of small holes, and a thermoelectric blower 10 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com