Working condition detecting method, device and system

A detection method and detection device technology, applied in the field of automation, can solve the problems of low reliability, low sensor sensitivity, short life, etc., and achieve the effect of improving reliability and sensitivity and avoiding complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 As shown, it is a flowchart of an embodiment of the working condition detection method of the present invention, and the method includes:

[0027] Step 101, collecting the image information of the belt conveyor;

[0028] Step 102 , analyzing and processing the above image information to determine the working condition of the above belt conveyor.

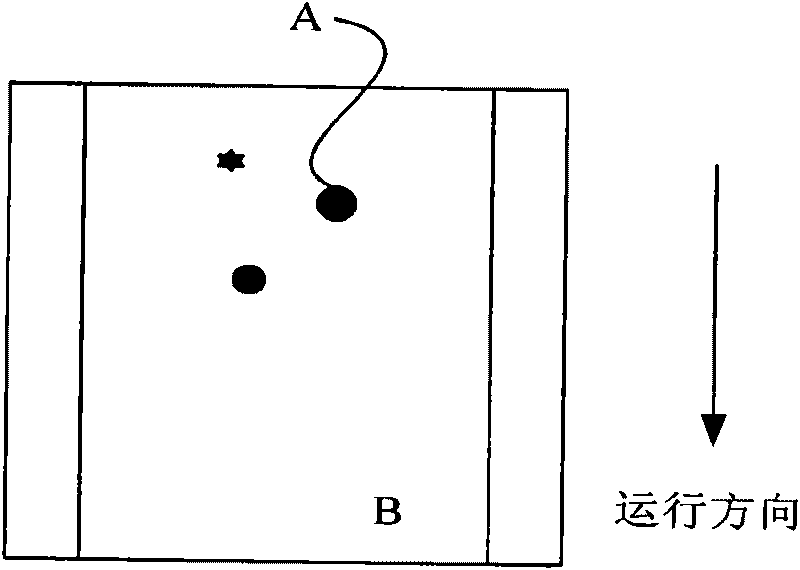

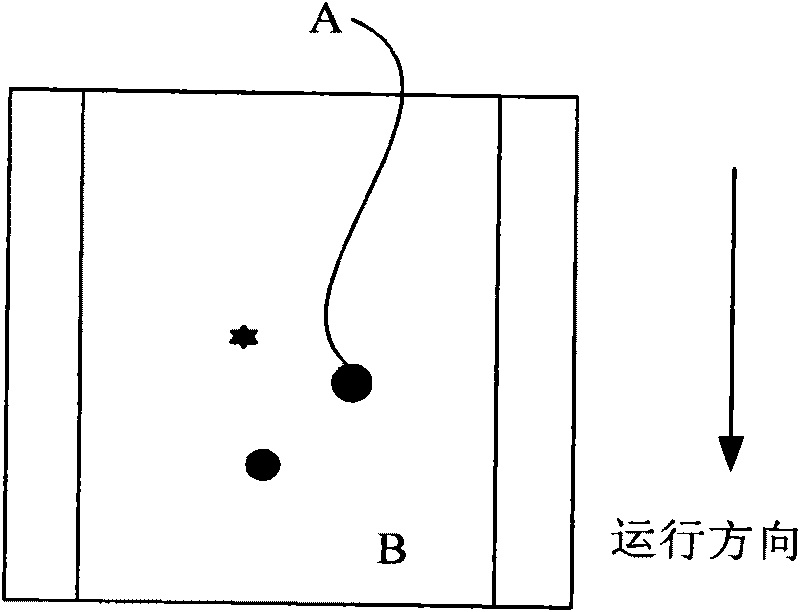

[0029] In the above step 101, the image information of the belt conveyor can be collected by setting a plurality of cameras above the belt conveyor; in the above step 102, the working conditions of the belt conveyor include many parameters, such as the belt conveyor Running speed, degree of deviation, degree of longitudinal tearing of the conveyor belt, distinction between smoke and dust, detection of stockpiling, detection of for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com