High bandwidth multimode fiber

A multi-mode optical fiber and high-bandwidth technology, which is applied in the field of optical communication, can solve problems such as the negative impact of multi-mode bandwidth, and achieve the effects of simple and effective manufacturing methods, improved bending resistance, and reduced microbending loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

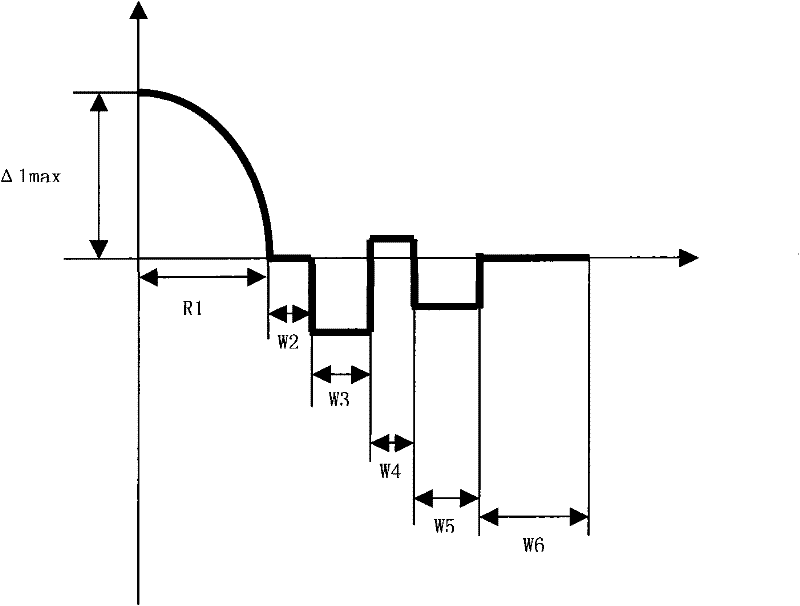

[0045] According to the design of the technical plan (as attached figure 1 Shown), and the manufacturing method of the present invention, prepared a group of prefabricated rods and drawing, adopting the double-layer coating of multimode optical fiber and the drawing speed of 600 m / min, the structure and main performance parameters of the optical fiber are shown in Table 1.

[0046] Table 1

[0047]

[0048] 1 turn 7.5mm bend

Embodiment 2

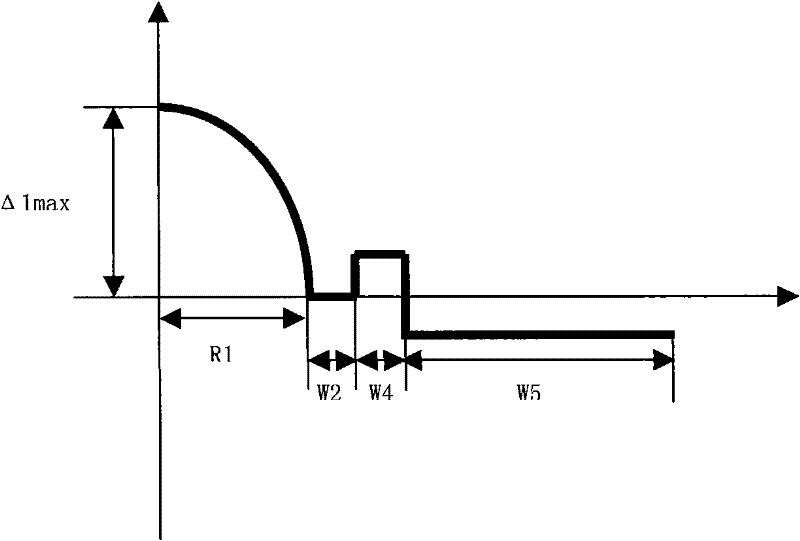

[0050] According to attached figure 2 According to the design and the manufacturing method of the present invention, a group of prefabricated rods were prepared and drawn, using double-layer coating of multimode optical fiber and a drawing speed of 600 m / min. The structure and main performance parameters of the optical fiber are shown in Table 2.

[0051] Table 2

[0052]

[0053] 1 turn 10mm bend

Embodiment 3

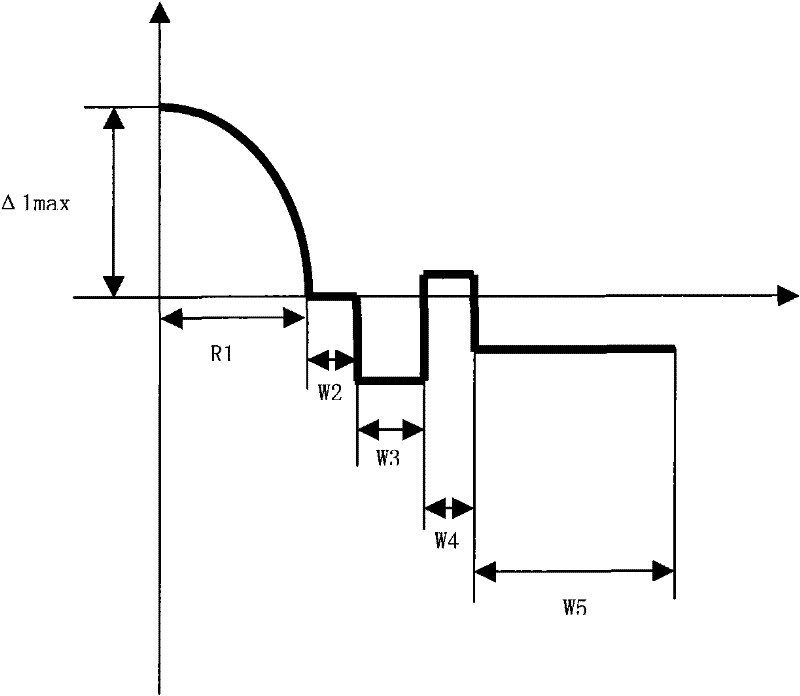

[0055] According to attached image 3 According to the design and the manufacturing method of the present invention, a group of preforms were prepared and drawn, using double-layer coating of multimode optical fiber and a drawing speed of 600 m / min. The structure and main performance parameters of the optical fiber are shown in Table 3.

[0056] table 3

[0057]

[0058] full injection bandwidth

[0059] The optical fiber refractive index profiles of the fourth to eighth embodiments of the present invention are as follows Figure 4-8 As shown, the main difference between the fourth embodiment and the third embodiment is that the relative refractive index difference Δ5% of the depressed outer cladding changes in a curve along the radial direction, and the curve is arc-shaped; the fifth embodiment and the first The main difference between the three embodiments is that the relative refractive index difference Δ5% of the sunken outer cladding is linearly decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com