Silicon wafer transferring arm and use method thereof

An arm, silicon wafer technology, applied in the field of silicon wafer transfer arm, can solve the problem of not being able to transfer silicon wafers at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

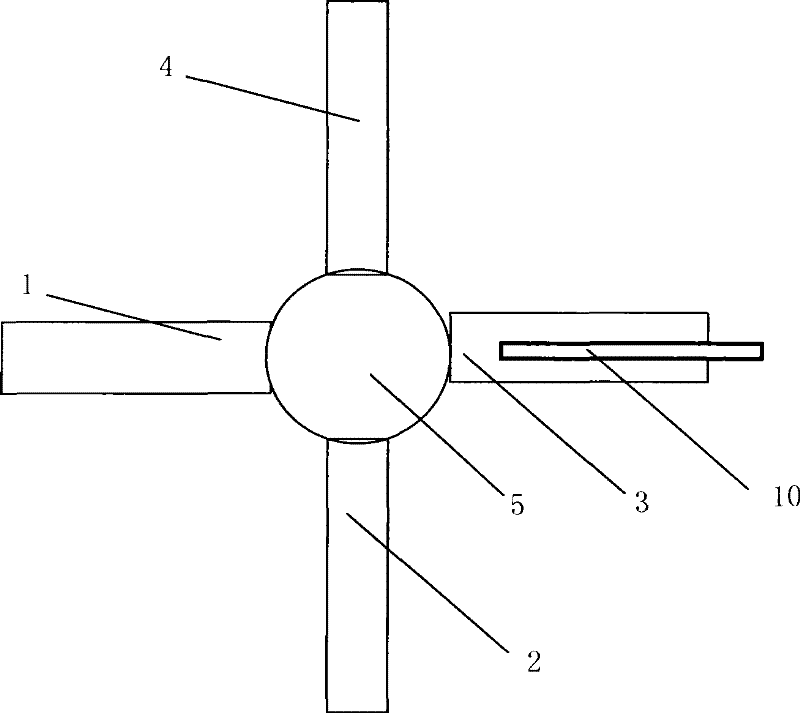

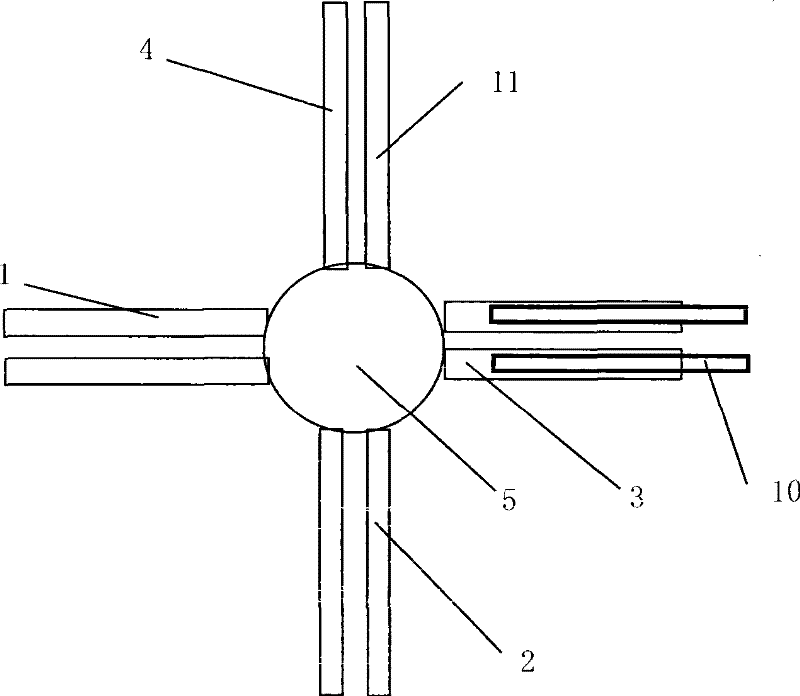

[0024] Such as figure 1 As shown, the silicon wafer transfer arm of the present invention includes arm supports 1, 2, 3, 4, which are respectively fixedly connected to the connector 5, and the arm supports 1, 2, 3, 4 form a cross shape with each other. The connector 5 is connected with the rotation control shaft, and the rotation control shaft is connected with the driving motor. The drive motor controls the rotation of the connector 5 by driving the rotation of the rotation control shaft.

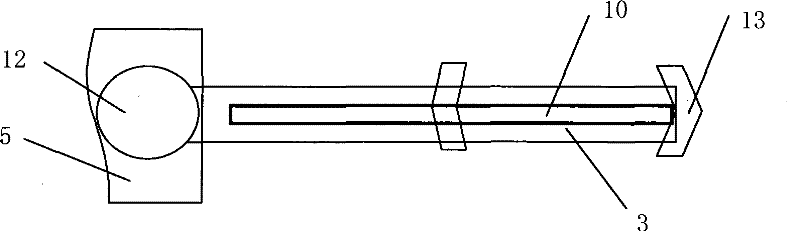

[0025] Such as image 3 , Figure 4 As shown, each arm bracket includes two clamping handles 11, and the two clamping handles 11 form a scissors shape, so that the arm bracket becomes a clamp that can be opened and closed. The curvature of the edge of the silicon wafer 10 is suitable. The silicon wafer 10 can be clamped along the circular edge of the silicon wafer 10 when the clips are closed.

[0026] The arc portion of the clamping handle 11 is fixedly provided with a plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com