Gravity heat pipe radiator for LED lamp radiation

A technology of gravity heat pipes and LED lamps, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., and can solve problems such as loss of gravity, poor heat dissipation effect, and poor gas-liquid circulation. , to achieve the effect of ensuring the gravity cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not intended to limit the present invention. The scope of protection of the present invention is subject to the content recorded in the claims. Without departing from the protection scope of the present invention.

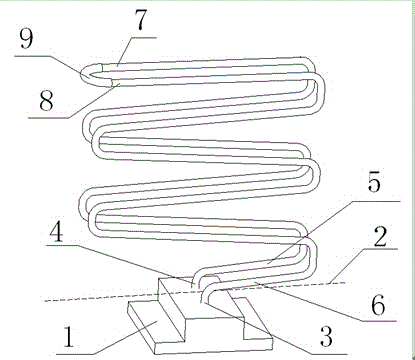

[0013] The overall structure of this embodiment is as follows figure 1 As shown, the rotation axis 2 is first determined on the horizontally placed evaporation chamber 1, and then the evaporation port 3 and the return port 4 are set on both sides of the rotation axis, and the evaporation pipeline 6 is drawn from the evaporation port 3 and circles upwards to the top. An evaporation horizontal tube 8 is formed. The evaporation horizontal tube is roughly parallel to the rotation axis 2. The evaporation pipelines are all in the same plane. The highest end of the evaporation horizontal tube has a connecting tube 9, which extends in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com