A current type double pwm high performance magnetic levitation high speed motor control system

A technology for high-speed motors and control systems, applied in the direction of current controllers, etc., can solve problems such as low power factor, large starting current, and energy waste, and achieve the effects of reducing the probability of damage, small device resistance, and reduced load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The invention will be further described below with reference to the accompanying drawings and specific embodiments.

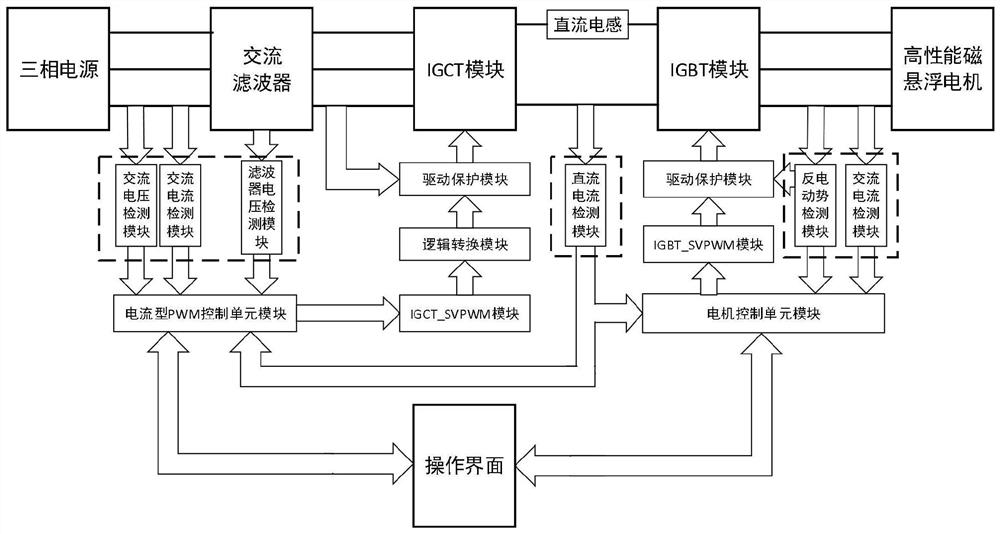

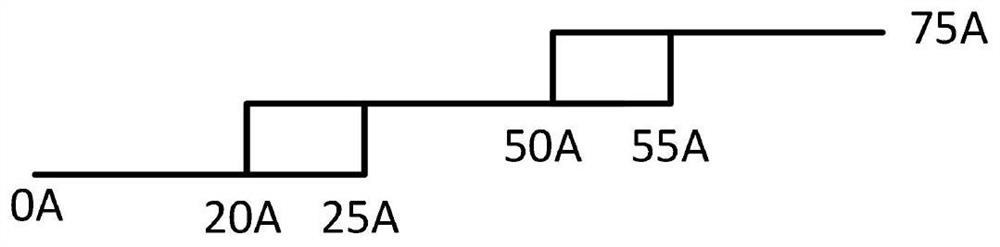

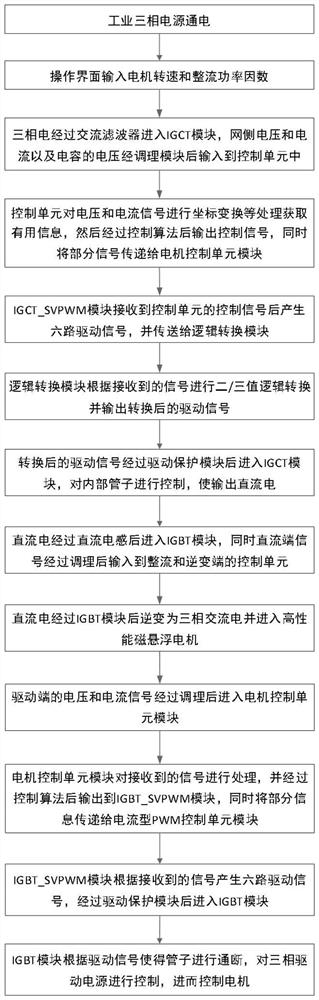

[0043]Such asfigure 1 ,image 3 As shown in the present invention, the motor is required from the normal start to the rated power operation, and the three-phase industrial electricity is entered into the IGCT module after passing the filter, and the voltage and current at this time. As and the voltage at the filter in the filter passes through the segment conditioning circuit, it enters the rectifier PWM control unit module, and the control module obtains useful information after the coordinate shift, the phase-locked loop, etc., combined with the control policy to obtain a control signal, and output To the IGCT_SVPWM module, the partial information is passed to the motor control unit module. The six-way drive signal generated by the IGCT_SVPWM module is logically converted to the drive protection module, then enter the IGCT module, control the output DC power valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com