Residual chlorine removal test device for secondary water supply tail end filter element

A test device and secondary water supply technology, which is applied in the direction of testing water, material inspection products, instruments, etc., can solve the problems of wasting water, achieve the effect of saving water and improving test efficiency

Pending Publication Date: 2022-06-21

重庆昕晟环保科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]

Although the above method can accurately test the effect of the filter to remove residual chlorine, because it uses the method of directly discharging the filtered water, it is a great waste of water.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

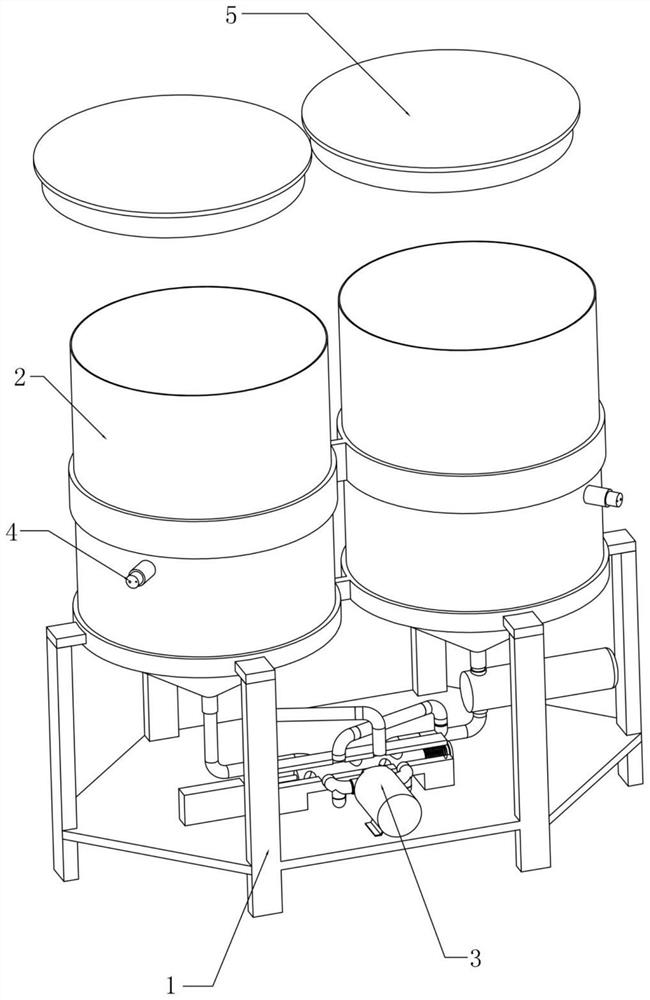

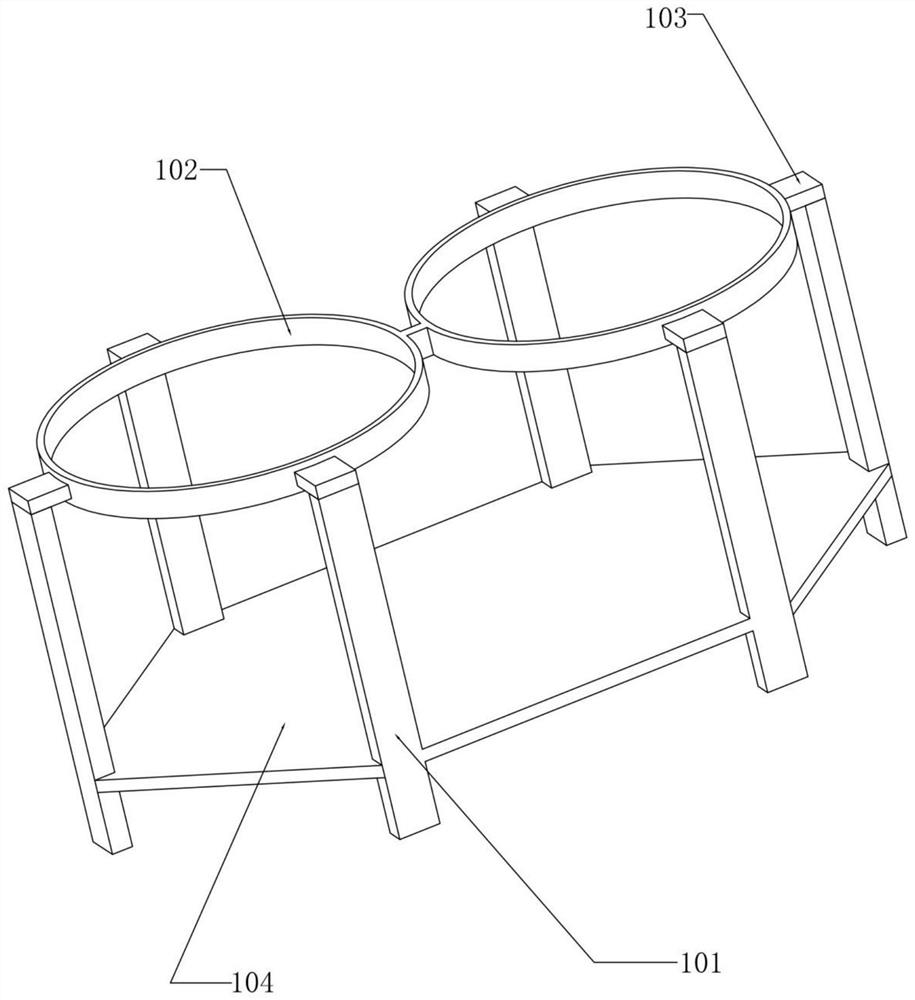

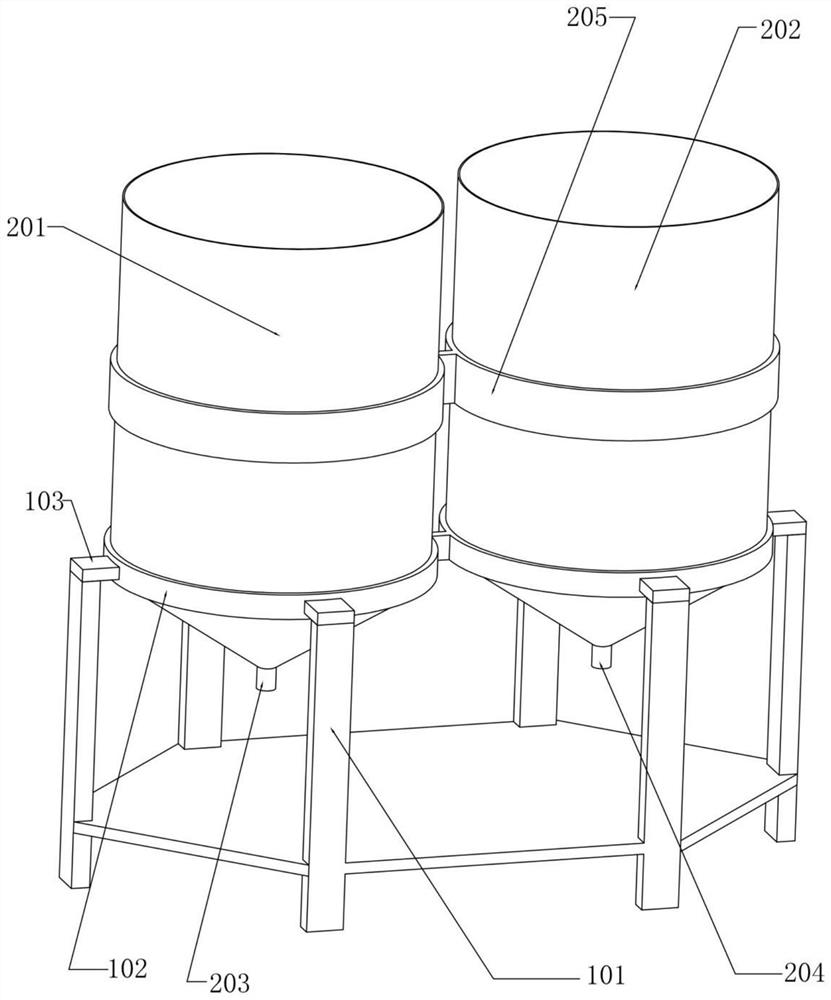

The invention provides a secondary water supply tail end filter element residual chlorine removal test device which comprises a bottom frame assembly, a filter barrel assembly, a filter exchange assembly, a residual chlorine detection assembly and a barrel cover, and the whole device takes the bottom frame assembly as a setting basis; a main barrel and an interchange barrel in the filter barrel assembly are arranged left and right, a filter interchange assembly is connected between the main barrel and the interchange barrel, any main pipeline at the bottom ends of the main barrel and the interchange barrel can be connected with a filter, and function interchange of the main barrel and the interchange barrel as a liquid chlorine adding barrel or a residual chlorine testing barrel can be realized through transverse movement of an interchange valve core in an interchange valve; meanwhile, connection and disconnection between the main barrel and the interchange barrel can be achieved; residual chlorine detection assemblies are arranged on the side walls of the main barrel and the interchange barrel at the same height, and the residual chlorine removal effect of the filter element can be detected; by adding original water once, the purpose of removing residual chlorine of the filter can be achieved, water sources are saved, and meanwhile a traditional pipeline valve device is omitted.

Description

technical field [0001] The invention relates to the technical field of residual chlorine test devices, in particular to a secondary water supply end filter element removal test device for residual chlorine. Background technique [0002] The safety of drinking water for high-level secondary water supply is a major issue related to the health and safety of the people, and the chlorination disinfection method is a drinking water disinfection process that will be adopted in my country for a long time to come. However, various disinfections caused by residual chlorine The drinking water safety problems caused by by-products cannot be ignored. The development of the household water purifier market is based on this background. At present, a variety of activated carbon filter water purifiers have appeared in the domestic market. Since the actual purification effect of each filter element is different, it is necessary to check the various specifications before leaving the factory. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/18G01N35/10

CPCG01N33/18G01N35/1009Y02A20/152

Inventor 程立高晓昆刘新贵

Owner 重庆昕晟环保科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com